Broken wood shaving device for building materials

A wood shaving and chipping technology, which is applied in the field of wood shaving devices for building materials, can solve the problems of waste, discarding, etc., achieve a good closing effect, and prevent the effect of flying wood chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

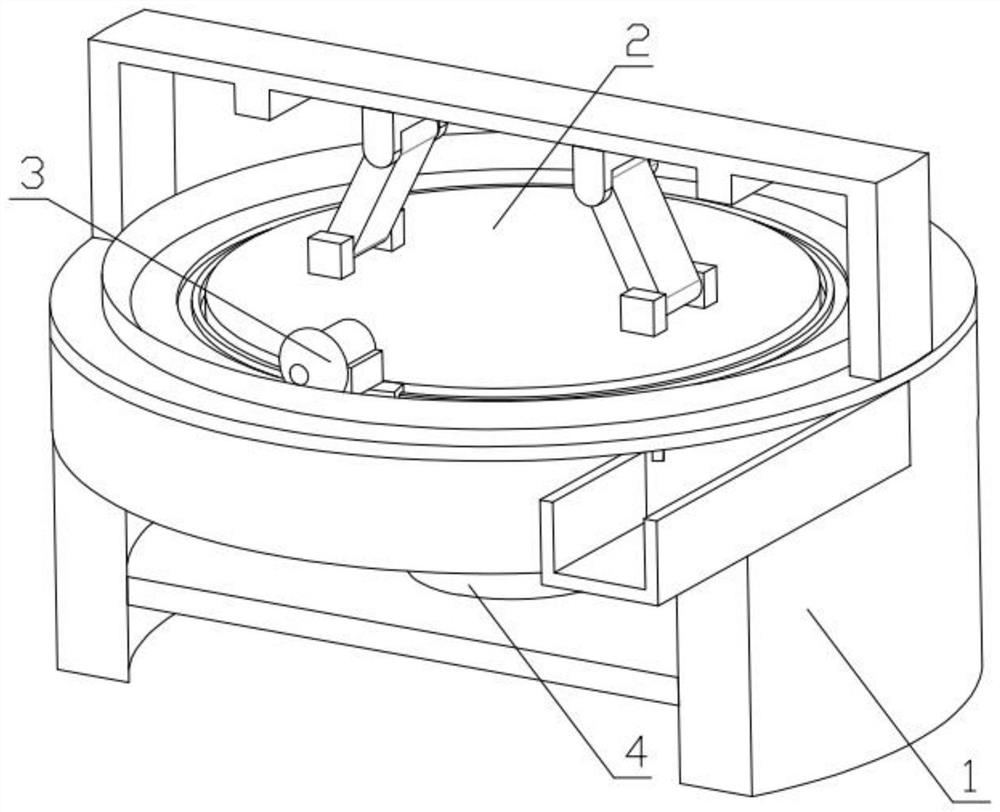

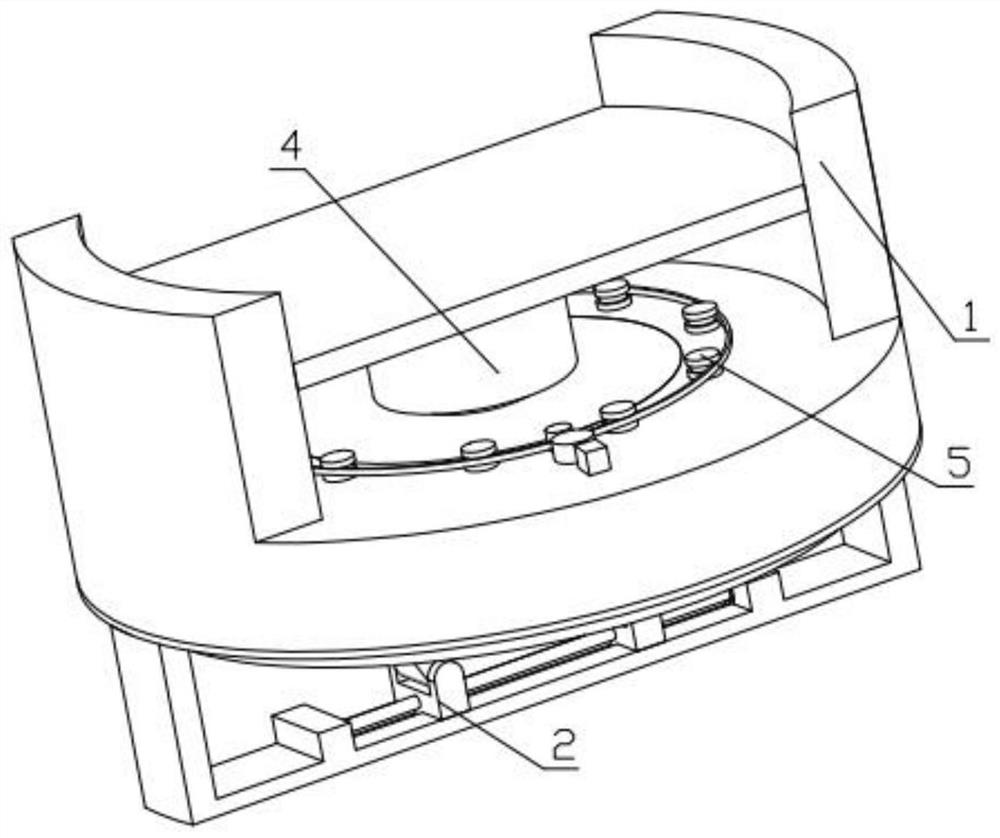

[0040] Combine below Figure 1-17 Description of this embodiment, a wood chipping device for building materials, including a circular cavity base 1, an upper sealing top cover 2, a shaving pushing mechanism 3, a rotating mechanism 4 and a shaving mechanism 5, the upper sealing top cover 2 Fixedly installed on the circular cavity base 1, the rotating mechanism 4 is fixedly installed on the circular cavity base 1, the shaving mechanism 5 is fixedly installed on the circular cavity base 1, and the shavings pushing mechanism 3 is fixedly installed on the circular cavity body base 1.

specific Embodiment approach 2

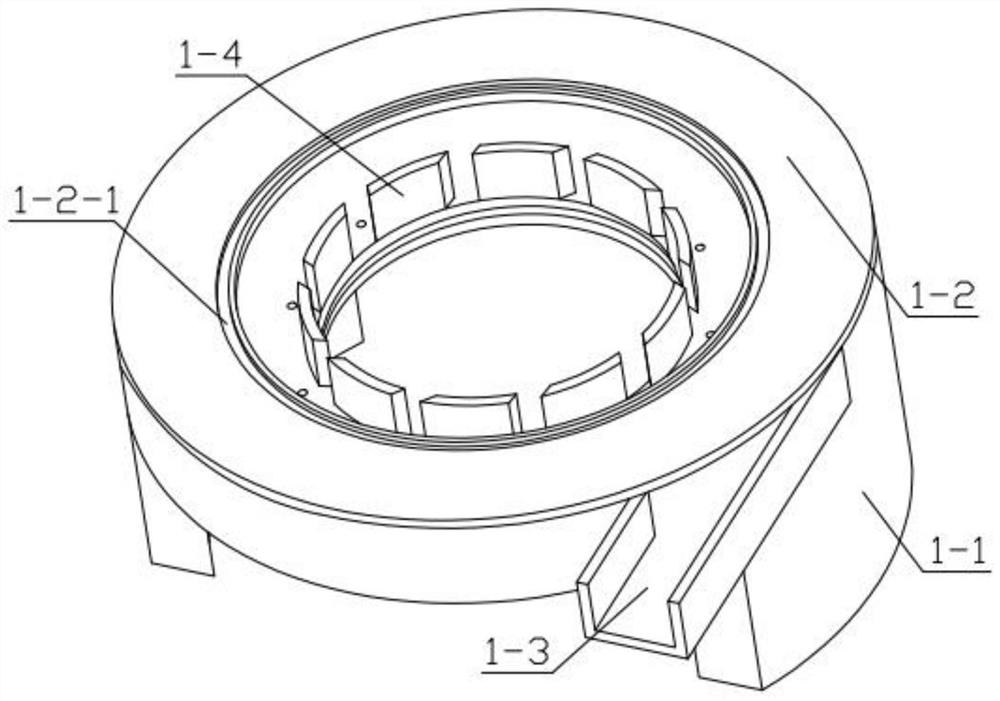

[0042] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 1, the circular cavity base 1 includes a main cavity base 1-1, an annular cover 1-2, a discharge chute 1-3, and an arc-shaped spacing plate 1-4, the base of the main cavity 1-1 is fixed with a discharge chute 1-3, the base of the main cavity 1-1 is fixed with a ring cover 1-2, and the ring cover 1-2 is provided with a ring chute 1-2-1, the arc-shaped spacing plate 1-4 is fixedly installed on the main cavity base 1-1.

specific Embodiment approach 3

[0044] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the second embodiment, the upper sealing top cover 2 includes a U-shaped frame 2-1, a circular sealing cover 2-2, a hinged leg 2-3, a slider 2- 4. Two-way threaded rod 2-5, motor 2-6 for sealing, motor 2-6 for sealing is fixedly installed on U-shaped frame 2-1, output end of motor 2-6 for sealing is fixedly installed with two-way threaded rod 2-6 5. The other end of the two-way threaded rod 2-5 is rotatably installed in the groove provided on the U-shaped frame 2-1, the slider 2-4 is threadedly connected with the two-way threaded rod 2-5, and the slider 2-4 is slidably installed on the In the groove provided on the U-shaped frame 2-1, the slide block 2-4 is hinged with the hinged leg 2-3, and the other end of the hinged leg 2-3 is hinged with the circular sealing cover 2-2, and the U-shaped frame 2 -1 is fixedly installed on the annular cover 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com