Powder grinding device for producing water-soluble coating

A technology of water-soluble paint and grinding device, which is applied in the direction of grain processing, etc., can solve the problem of filter clogging and other problems, and achieve the effect of preventing clogging, efficient grinding and solving clogging

Active Publication Date: 2018-06-15

宁波隆锐机械制造有限公司

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a powder grinding device for producing water-soluble paints, to solve the problem that the filter screen is prone to clogging after powder grinding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

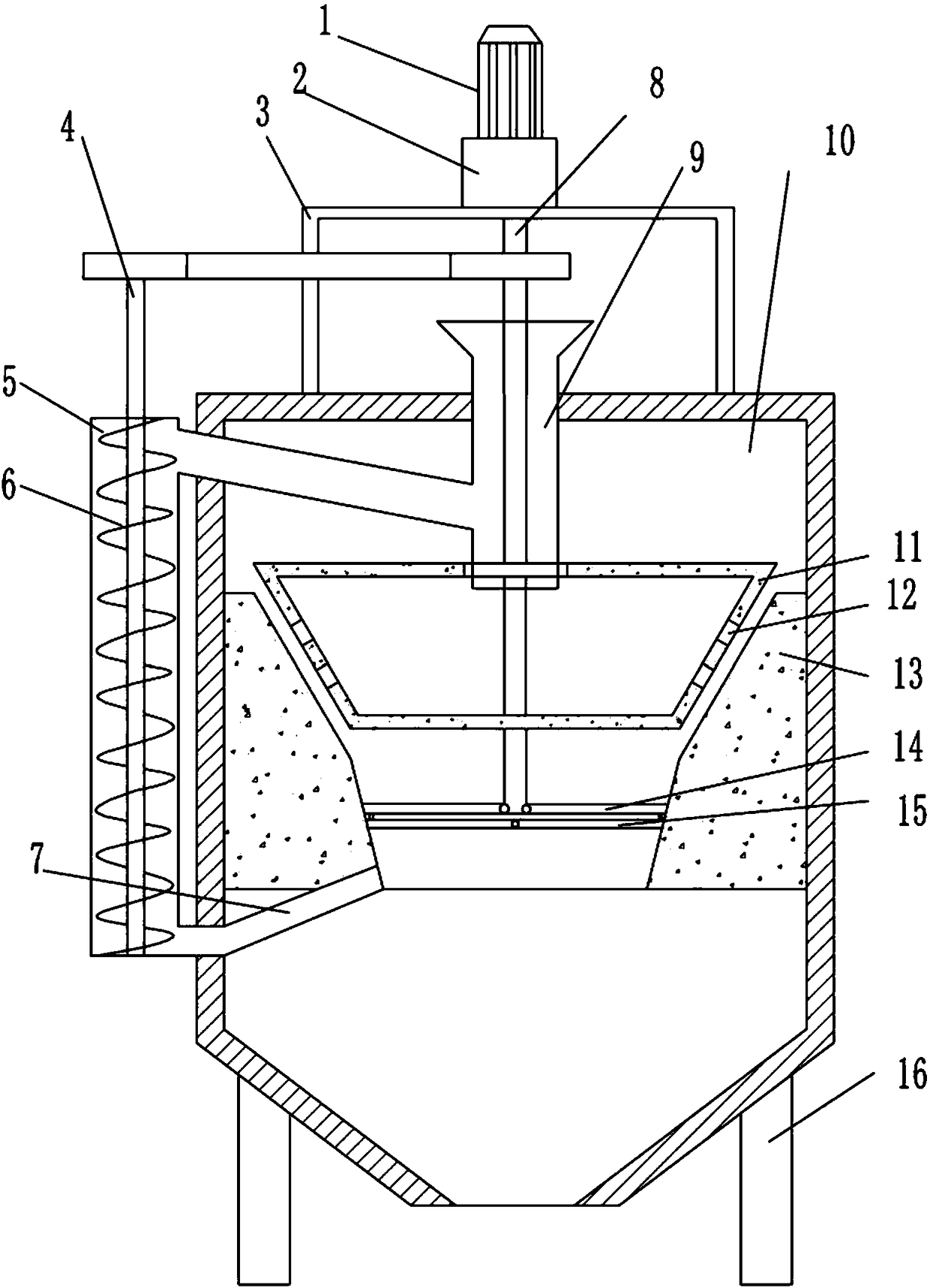

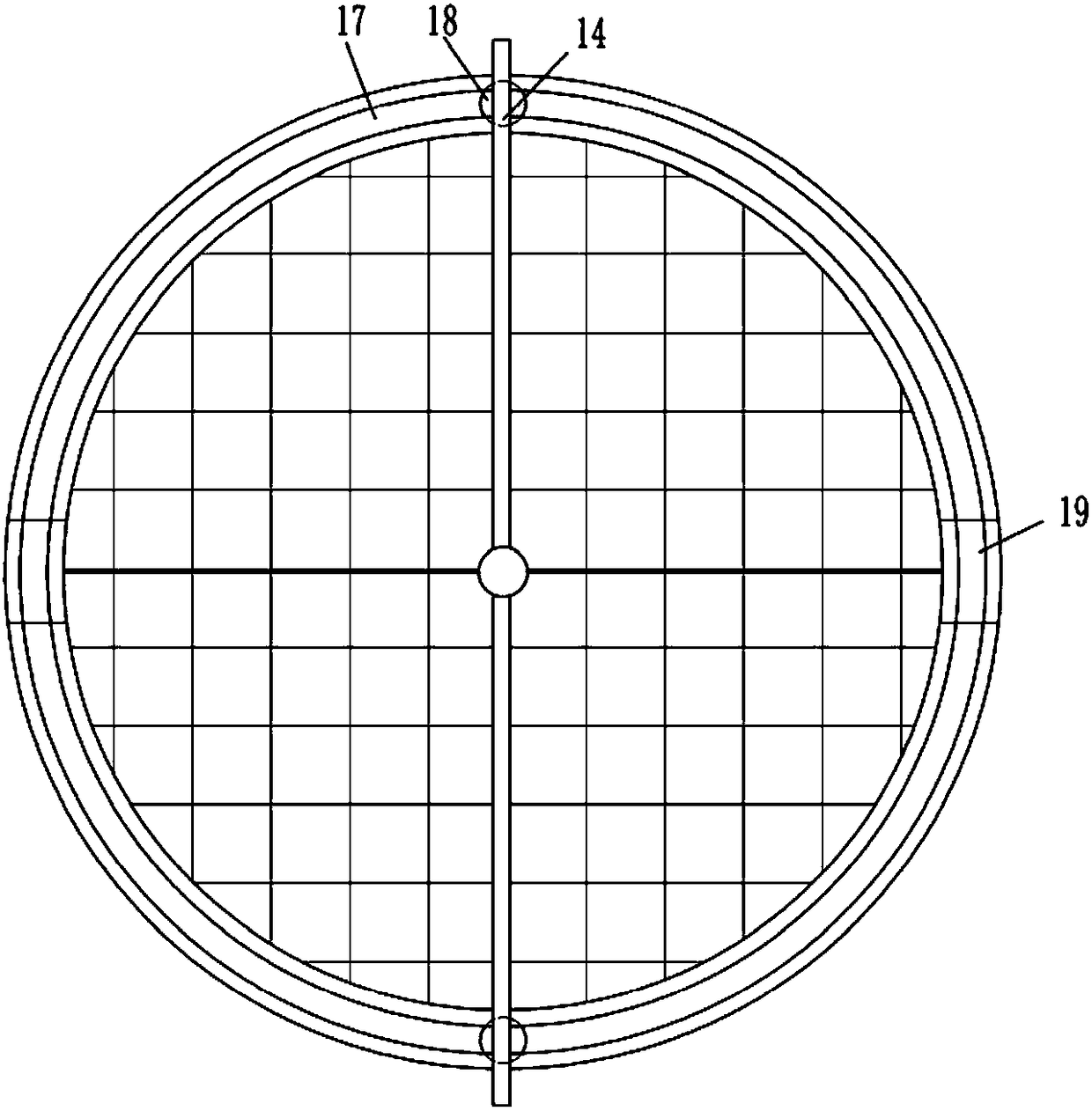

The invention belongs to the technical field of powder processing equipment, and particularly discloses a powder grinding device for producing a water-soluble coating. The powder grinding device comprises a processing barrel and a circulating barrel; a movable grinding block and a fixed grinding block which can be coordinated to grind powder are arranged in the processing barrel; the interior of the movable grinding block is hollow; sieve holes are formed in the side wall of the movable grinding block; a funnel-shaped channel is formed in the fixed grinding block; a fixed shaft is arranged onthe inner wall of the movable grinding block, and a closed curve sliding chute is formed in the inner wall of the movable grinding block; semicircular filter screens are hinged to the two sides of thefixed shaft; grooves are formed in the circumferential lines of the filter screens; a motor is arranged at the upper end of the processing barrel and is connected with a rotating shaft, and the rotating shaft can drive the movable grinding block to rotate; two movable rods are hinged to the bottom end of the rotating shaft and are connected in the sliding chute and the grooves in a sliding mode;a circulating material port is formed in the fixed grinding block; a spiral conveying mechanism is connected outside the circulating material port; and the upper end of the circulating barrel communicates with a feeding pipe. According to the scheme of the powder grinding device, the phenomenon that the filter screens are blocked after the powder is ground can be avoided, and unqualified powder can be circularly ground.

Description

technical field [0001] The invention belongs to the technical field of powder material processing equipment, in particular to a powder material grinding device for producing water-soluble paint. Background technique [0002] Grinding of powder is needed in the production of water-soluble paint. The traditional powder mill uses a central axis to rotate, and then drives two cylindrical grinding wheels to grind the powder in the grinding plate. When the existing device screens the processed powder, it only has a filter plate at the bottom of the discharge port to screen the powder. This screening method is easy to block the screening hole, which is not conducive to the discharge of the material. Contents of the invention [0003] The object of the present invention is to provide a powder material grinding device for producing water-soluble paint, so as to solve the problem that the filter screen is easily blocked after the powder material is ground. [0004] In order to achi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02C19/00B02C23/02B02C23/14B02C23/16B02C23/00

CPCB02C19/00B02C23/00B02C23/02B02C23/14B02C23/16B02C2023/165

Inventor 王健

Owner 宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com