Polishing device for outer surfaces of brake linings

A brake pad and outer surface technology, which is applied in the field of brake pad outer surface grinding devices, can solve the problems of increased production costs, large changes in friction coefficient, and low processing efficiency of brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

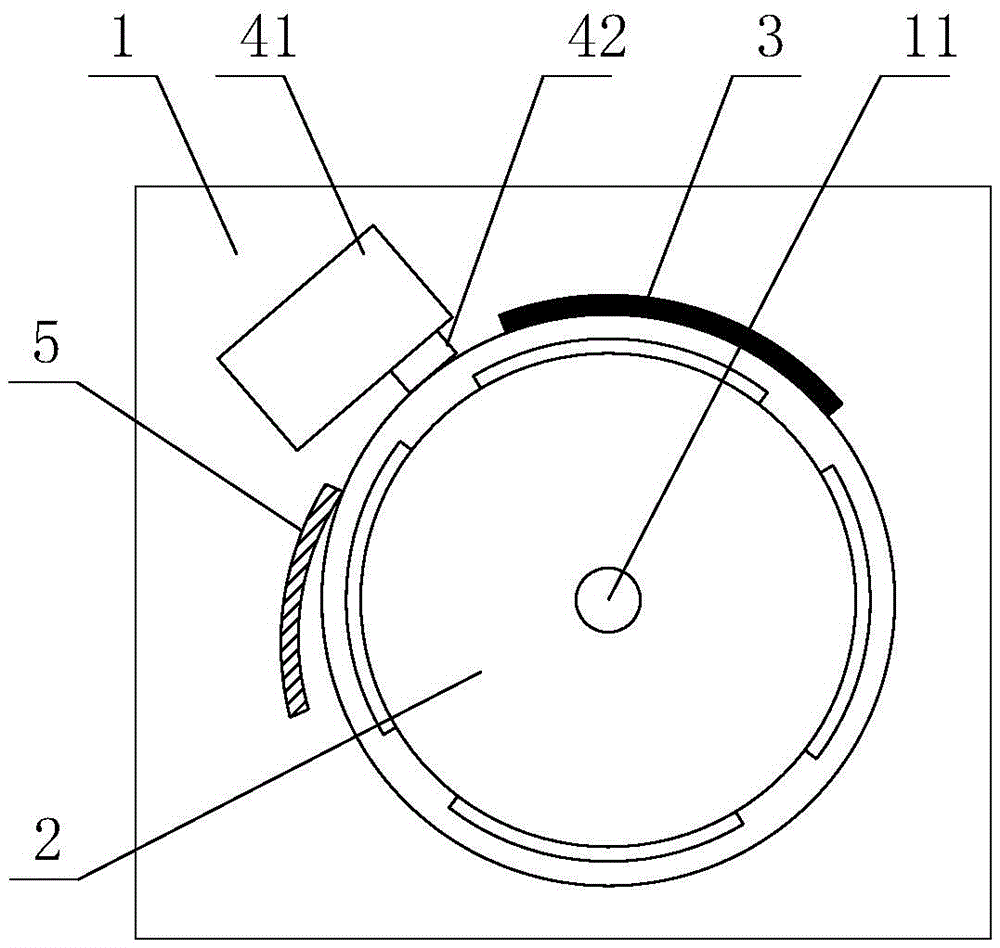

[0014] like figure 1 as shown, figure 1 It is a structural schematic diagram of a grinding device for the outer surface of a brake pad proposed by the present invention.

[0015] refer to figure 1 , a kind of brake pad outer surface polishing device that the present invention proposes, comprises: base 1, round table 2, polishing mechanism;

[0016] The base 1 is provided with a vertically arranged rotating shaft 11, and the round table 2 is rotatably mounted on the base 1 through the rotating shaft 11. The round table 2 includes a mounting part and a supporting part, the mounting part is located above the supporting part, and the outer diameter of the supporting part is larger than that of the mounting part. diameter, the outer wall of the installation part is provided with a plurality of brake pad installation positions, and the plurality of brake pad installation positions are evenly distributed on the outer circumference of the installation part. On the base 1 and on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com