Method for regenerating FCC waste catalyst via microwave assistance

A waste catalyst, microwave-assisted technology, used in molecular sieve catalysts, chemical instruments and methods, catalyst regeneration/reactivation, etc., can solve the problems of no longer reuse, long operation time, complicated process, etc., to achieve structural integrity and recovery rate. High, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

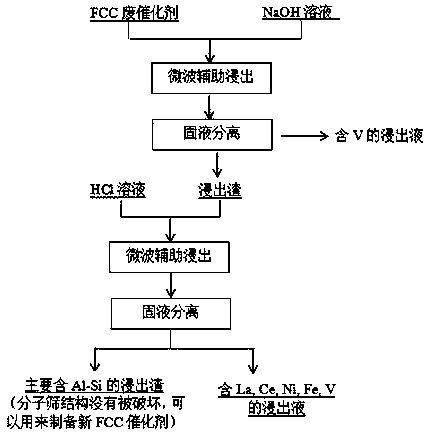

[0020] Such as figure 1 Shown, this microwave-assisted regeneration FCC spent catalyst method, its specific steps are as follows:

[0021] Step 1. First, the spent FCC catalyst (chemical composition includes the following mass percentage components: Al25.95%, Si18.39%, Ce2.05%, La1.09%, V0.59%, Fe0.48%, Ni0. 56%) in a muffle furnace at 600°C for 1 hour, and then mixed with a sodium hydroxide solution with a concentration of 0.1mol / L according to a liquid-solid ratio of 5:1mL / g. After the microwave radiation power is 1600W, the microwave leaching temperature is Alkali leaching at 90°C for 30 minutes to obtain alkali leaching slag and vanadium-containing leaching solution; the removal rate of V after alkali leaching was 32.3%;

[0022] Step 2. Mix the alkali leaching slag obtained in step 1 with the hydrochloric acid solution with a concentration of 5wt% according to the liquid-solid ratio of 10:1mL / g, and then acid-leach for 30min under the conditions of microwave radiation po...

Embodiment 2

[0026] Such as figure 1 Shown, this microwave-assisted regeneration FCC spent catalyst method, its specific steps are as follows:

[0027] Step 1. First, the spent FCC catalyst (chemical composition includes the following mass percentage components: Al26.04%, Si18.69%, Ce2.01%, La1.11%, V0.59%, Fe0.46%, Ni0. 52%) in a muffle furnace at 600°C for 4 hours, and then mixed with a sodium hydroxide solution with a concentration of 0.5mol / L according to a liquid-solid ratio of 5:1mL / g. After the microwave radiation power is 1800W, the microwave leaching temperature is Alkali leaching at 100°C for 30 minutes yielded alkali leaching slag and vanadium-containing leaching solution; the removal rate of V after alkali leaching was 35.59%;

[0028] Step 2. Mix the alkali leaching slag obtained in step 1 with the hydrochloric acid solution with a concentration of 6wt% according to the liquid-solid ratio of 5:1mL / g, and then acid-leach for 20 minutes under the conditions of microwave radiati...

Embodiment 3

[0031] Such as figure 1 Shown, this microwave-assisted regeneration FCC spent catalyst method, its specific steps are as follows:

[0032] Step 1. First, the spent FCC catalyst (chemical composition includes the following mass percentage components: Al26.04%, Si18.69%, Ce2.01%, La1.11%, V0.59%, Fe0.46%, Ni0. 52%) in a muffle furnace at 700°C for 2 hours, and then mixed with a sodium hydroxide solution with a concentration of 0.8mol / L at a liquid-solid ratio of 15:1mL / g, then the microwave radiation power is 400W, and the microwave leaching temperature is Alkali leaching at 50°C for 60 minutes yielded alkali leaching slag and vanadium-containing leaching solution; the removal rate of V after alkali leaching was 27.7%;

[0033] Step 2. Mix the alkali leaching residue obtained in step 1 with the hydrochloric acid solution with a concentration of 1wt% according to the liquid-solid ratio of 3:1mL / g, and then acid-leach for 60min under the conditions of microwave radiation power of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com