Filtering fabric having three-dimensional structure and preparation method thereof

A technology for filtering fabrics and three-dimensional structures, applied in fabrics, filtration separation, membrane filters, etc., can solve the problems of low temperature resistance, weak mechanical properties of filter fabrics, etc., and achieve the effect of low cost, light weight and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

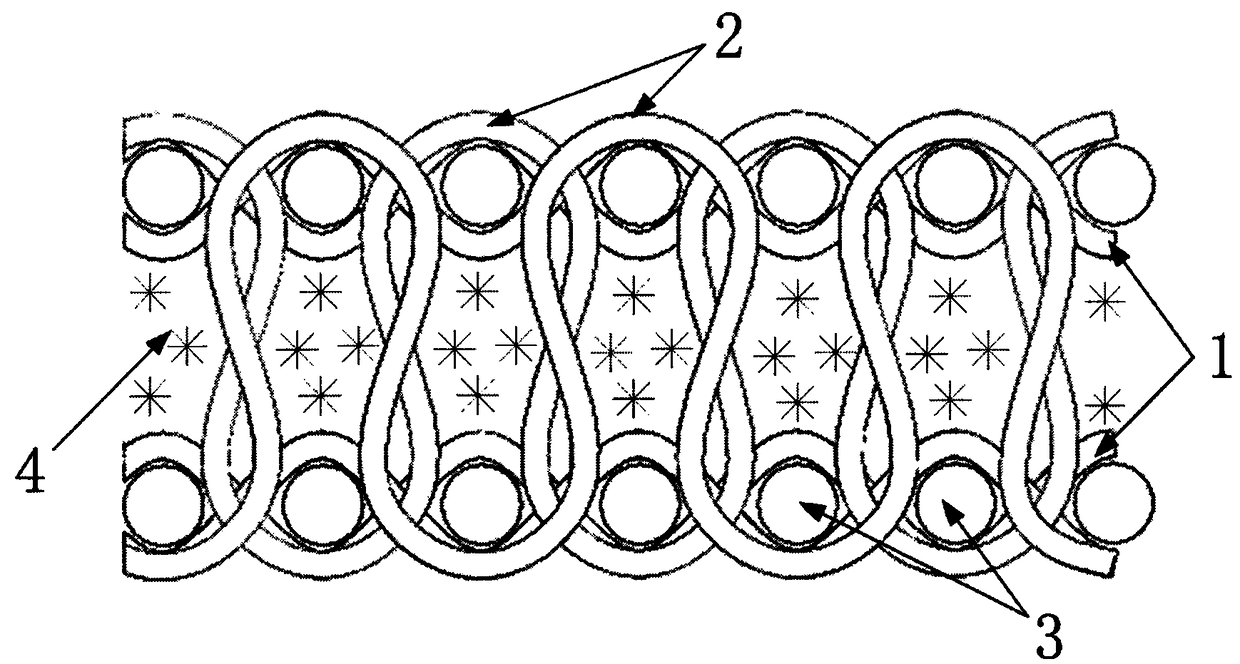

[0024] 1. Three-dimensional structured liquid filter fabric

[0025] Select polyester fiber as warp yarn 1, weft yarn 3 and spacer yarn 2, and the fineness is 200tex. Weaving on a three-dimensional arrow shaft loom, using a spacer to control the height of the spacer yarn 2 during the weaving process. The multi-shed weaving method is adopted, and the multi-stroke cylinder is used as the transmission mechanism to control the movement of the heald frame to control the movement of the warp, and the rapier mechanism is used for weft insertion. The warp and weft density are 20 threads / cm, the fabric design width is 40 cm, and the length is 40 cm. The spacer is an aluminum foil plate with a length of 50 cm, a height of 5 mm, and a width of 1 mm. The filter material 4 adopts a carbon nanotube film (Suzhou Jiedi Nano Material Co., Ltd.) with a length of 40 cm, a width of 5 mm, and a thickness of 10 microns.

[0026] 2. Preparation method

[0027] (1) Three-dimensional spacer fabric...

Embodiment 2

[0033] 1. High temperature resistant three-dimensional structure liquid filter fabric

[0034] Aramid fiber is selected as warp yarn 1, weft yarn 3 and spacer yarn 2, and the fineness is 300tex. Weaving on a three-dimensional arrow shaft loom, using a spacer to control the height of the spacer yarn 2 during the weaving process. The multi-shed weaving method is adopted, and the multi-stroke cylinder is used as the transmission mechanism to control the movement of the warp 1 by controlling the lifting of the heald frame, and the rapier mechanism is used for weft insertion. The warp and weft density are 18 threads / cm, the fabric design width is 40 cm, and the length is 40 cm. The spacer is an aluminum foil plate with a length of 50 cm, a height of 5 mm, and a width of 1 mm. The filter material 4 adopts a carbon nanotube film (Suzhou Jiedi Nano Material Co., Ltd.) with a length of 40 cm, a width of 5 mm, and a thickness of 10 microns.

[0035] 2. Preparation method

[0036] (1...

Embodiment 3

[0042] 1. High-strength three-dimensional structure liquid filter fabric

[0043]Aramid fiber is selected as warp yarn 1, weft yarn 3 and spacer yarn 2, and the fineness is 200tex. Weaving on a three-dimensional arrow shaft loom, using a spacer to control the height of the spacer yarn 2 during the weaving process. The multi-shed weaving method is adopted, and the multi-stroke cylinder is used as the transmission mechanism to control the movement of the warp 1 by controlling the lifting of the heald frame, and the rapier mechanism is used for weft insertion. The warp and weft density are 20 threads / cm, the fabric design width is 40 cm, and the length is 40 cm. The spacer is an aluminum foil plate with a length of 50 cm, a height of 5 mm, and a width of 1 mm. The carbon nanotube film (Suzhou Jiedi Nano Material Co., Ltd.) is 40 cm in length, 5 mm in width, and 10 microns in thickness.

[0044] 2. Preparation method

[0045] (1) Three-dimensional spacer fabric structure woven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com