Preparation method of Pd-M nano composite catalyst loaded with reduced graphene oxide (RGO)

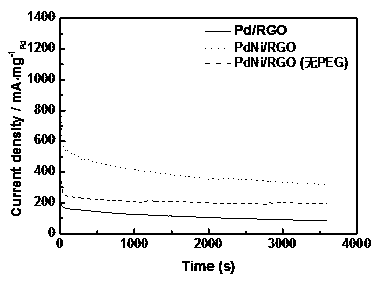

A nano-composite and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as low stability, complicated processing process, and easy agglomeration of catalysts, so as to achieve improved catalytic performance, simple synthesis method, and improved catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for preparing the PdCo / RGO catalyst by the next step chemical reduction method under the protection condition of polyPEG, the specific steps are as follows:

[0039](1) Preparation of GO: First, 115 mL of 98% concentrated H 2 SO 4 , 5g natural scaly graphite powder and 2.5gNaNO 3 Mix and stir for 4h, place the mixed solution in an ice bath, and add 15gKMnO 4 ; Place the above mixed solution in a water bath at 35°C, stir for 0.5h; then transfer the liquid to 230mL deionized water at 98°C, let it stand for 5min, add warm water to dilute to 550mL, add 35mLH 2 o 2 remove the remaining H 2 SO 4 and KMnO 4 ; Finally, wash with 5% HCl solution and deionized water, filter with suction, and then centrifuge to obtain GO colloid, and freeze-dry the colloid to obtain GO.

[0040] (2) The preparation method of PdCo / RGO composite catalyst synthesized in the next step under PEG protection conditions: Weigh 10 mg GO prepared in (1) and ultrasonically disperse in 50 mL...

Embodiment 2

[0046] Utilize the method for preparing PdNi / RGO catalyst by next-step chemical reduction under PEG protection conditions, its specific steps are as follows:

[0047] (1) Preparation of GO: First, 115 mL of 98% concentrated H 2 SO 4 , 5g natural scaly graphite powder and 2.5gNaNO 3 Mix and stir for 4h, place the mixed solution in an ice bath, and add 15gKMnO 4 ; Place the above mixed solution in a water bath at 35°C, stir for 0.5h; then transfer the liquid to 230mL deionized water at 98°C, let it stand for 5min, add warm water to dilute to 550mL, add 35mLH 2 o 2 to remove the remaining H 2 SO 4 and KMnO 4 ; Finally, wash with 5% HCl solution and deionized water, filter with suction, and then centrifuge to obtain GO colloid, and freeze-dry the colloid to obtain GO.

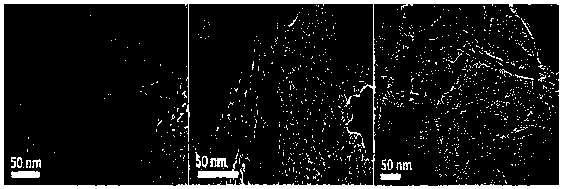

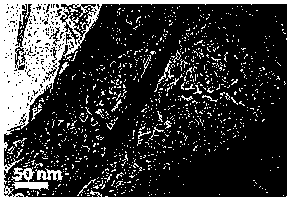

[0048] (2) PEG protection conditions The preparation method of the next step to synthesize PdNi / RGO composite catalyst: Weigh 10 mg GO prepared in (1) and ultrasonically disperse in 20 mL ultrapure water for...

Embodiment 3

[0054] The method for preparing the PdCu / RGO catalyst by chemical reduction method in the next step of PEG protection condition, its concrete steps are as follows:

[0055] (1) Preparation of GO: First, 115 mL of 98% concentrated H 2 SO 4, 5g natural scaly graphite powder and 2.5gNaNO 3 Mix and stir for 4h, place the mixed solution in an ice bath, and add 15gKMnO 4 ; Place the above mixed solution in a water bath at 35°C, stir for 0.5h; then transfer the liquid to 230mL deionized water at 98°C, let it stand for 5min, add warm water to dilute to 550mL, add 35mLH 2 o 2 Restore the remaining H 2 SO 4 and KMnO 4 ; Finally, wash with 5% HCl solution and deionized water, filter with suction, and then centrifuge to obtain GO colloid, and freeze-dry the colloid to obtain GO.

[0056] (2) PEG protection conditions The preparation method of the next step to synthesize PdCu / RGO composite catalyst: Weigh 10 mg GO prepared in (1) and ultrasonically disperse in 5 mL ultrapure water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com