Heat treatment process of drill rod pipe body

A technology of drill pipe and process, which is applied in the field of heat treatment process of pipe body, can solve the problems that the tensile properties of drill pipe body cannot meet the requirements, and it is difficult to meet the technical requirements of V150 steel grade drill pipe, etc., and achieve simple heat treatment steps, Good impact performance and reasonable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

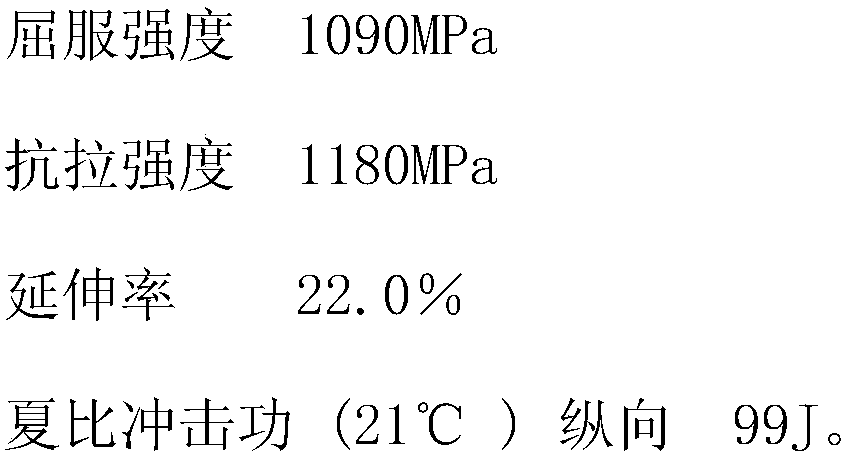

Examples

Embodiment Construction

[0019] The invention will be described in further detail below through specific embodiments.

[0020] The drill pipe body of a certain company is used, and its chemical composition is C: 0.26, Cr: 0.98, Mo: 0.64, V: 0.005, Si: 0.22, Mn: 0.75, Cu: 0.03, S: 0.001, P: 0.008, The balance is Fe, and the unit is mass percent. Follow the steps below for heat treatment:

[0021] ①Quenching

[0022] a. Transport the drill pipe body to a step-by-step quenching furnace whose temperature is raised to 910°C, and keep it warm for 60 minutes;

[0023] b. After the drill pipe body comes out of the furnace, it enters the quenching liquid at 23°C within 15 seconds. The quenching liquid is tap water and rotates at a rate of 88 rpm. The quenching time is 40 seconds, and the temperature of the quenching liquid is adjusted by the cooling tower. , The drill pipe body rotates at a certain speed for rapid and uniform quenching to form a fine and uniform grain structure.

[0024] ② Tempering

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com