Multi-meter integrated acquisition communication terminal box

A terminal box and communication technology, applied in the field of power equipment, can solve the problems of insufficient mechanical strength of polymer materials, unutilized and popularized use, low thermal deformation temperature, etc., and achieve excellent thermal stability, good physical and mechanical properties, and decomposition temperature. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A multi-meter-in-one collection communication terminal box, which includes a box body, and the box body is prepared according to the following process:

[0017] Step 1) Mix chlorinated butyl rubber, EPDM rubber, methyl vinyl silicone rubber, polycarbonate and glass fiber according to the mass ratio of 80:50:20:10:1 to obtain a mixture, and mix The materials were blended in a single-screw extruder, granulated to obtain the base resin, and then entered into an internal mixer for banburying. The banburying temperature was 70°C and the banburying time was 3 minutes to prepare the main material;

[0018] Step 2) Mix boron nitride, silicon carbide and alumina according to the mass ratio of 2:1:1, put them into a ball mill and ball mill to 200 mesh powder, which is auxiliary material A;

[0019] Step 3) Mix molybdenum disulfide and graphite according to the mass ratio of 2:1 to obtain a mixture, then add it to N-methylpyrrolidone accounting for twice the weight of the mixture,...

Embodiment 2

[0023] A multi-meter-in-one collection communication terminal box, which includes a box body, and the box body is prepared according to the following process:

[0024] Step 1) Mix chlorinated butyl rubber, EPDM rubber, methyl vinyl silicone rubber, polycarbonate and glass fiber according to the mass ratio of 80:50:20:10:1 to obtain a mixture, and mix The materials were blended in a single-screw extruder, granulated to obtain the base resin, and then entered into an internal mixer for banburying. The banburying temperature was 70°C and the banburying time was 3 minutes to prepare the main material;

[0025] Step 2) Mix boron nitride, silicon carbide and alumina according to the mass ratio of 2:1:1, put them into a ball mill and ball mill to 200 mesh powder, which is auxiliary material A;

[0026] Step 3) Mix molybdenum disulfide and graphite according to the mass ratio of 2:1 to obtain a mixture, then add it to N-methylpyrrolidone accounting for twice the weight of the mixture,...

Embodiment 3

[0030] The performance test of the casing prepared by the present invention:

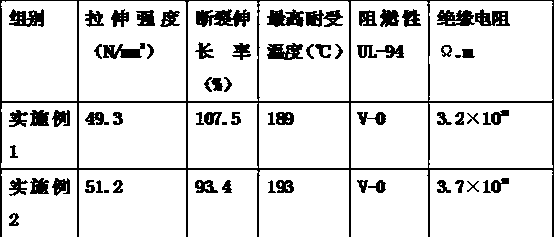

[0031] 1. The tensile strength, elongation at break, high temperature resistance, flame retardancy, and insulation performance of the boxes prepared in Example 1 and Example 2 of the present invention are better, and the specific test results can be seen in Table 1:

[0032] Table 1

[0033]

[0034] 2. Corrosion resistance: soak the box body material in 10% dilute hydrochloric acid solution or 8% sodium hydroxide solution or 8% sodium chloride solution for 480 hours, there is no obvious change in the appearance and performance parameters. The box material has good acid, alkali and salt resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com