A kind of preparation method of c/c composite material high temperature anti-oxidation coating

A high-temperature anti-oxidation, composite material technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of inability to deposit the coating, poor electrical conductivity, increased difficulty, etc., to change the breakdown discharge mechanism, improve electrical conductivity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

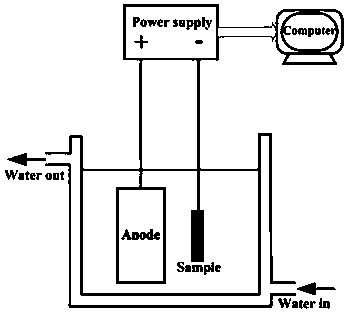

Embodiment 1

[0039] Configure Y (NO 3 ) 3 with Al(NO 3 ) 3 The molar ratio is 3:1, the total concentration is 1mol / L aqueous solution, add 10g / L nano-silicon powder, high-purity graphite is used as anode, C / C composite material is used as cathode, and the surface area ratio of anode and cathode is 2:1. Such as figure 1 shown. Turn on the pulse power supply and adjust the voltage to 120V, the deposition time is 5min, and the solution temperature is maintained at 20±5°C. After the preparation is completed, put it into a vacuum sintering furnace for sintering, the sintering temperature is 1600° C., and the sintering time is 3 hours. The final coating thickness obtained was 86 μm with a porosity of 14.9%.

Embodiment 2

[0041]The same process as in Example 1 was adopted, the deposition voltage was 150V, the deposition time was 5 min, and the same sintering process as in Example 1 was adopted. The final coating thickness obtained was 88 μm with a porosity of 15.5%.

Embodiment 3

[0043] The same process as in Example 1 was adopted, the deposition voltage was 150V, the deposition time was 10 min, and the same sintering process as in Example 1 was adopted. The final coating thickness obtained was 98 μm with a porosity of 14.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com