Palm activated carbon fiber and preparation method and application thereof

A technology of activated carbon fiber and palm fiber, which is applied in the direction of fiber chemical characteristics, chemical instruments and methods, carbon compounds, etc., can solve the problems of heating equipment energy consumption, large amount of protective gas, cumbersome operation steps, and increased preparation costs, so as to avoid The effect of equipment corrosion and environmental pollution, simple preparation process and fast preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Present embodiment provides a kind of preparation of palm activated carbon fiber, comprising:

[0030] (1) Wash the palm fiber with distilled water, remove the surface dust, and then put it in a constant temperature blast drying oven at 103±2°C for 24 hours;

[0031] (2) Heat the cleaned and dried palm fiber from room temperature to 700°C at a heating rate of 4°C / min, and keep it at 700°C for 60 minutes. The whole process is in a nitrogen gas atmosphere, and the flow rate of nitrogen gas is 200mL / min, feed water vapor while keeping warm, the water vapor flow rate is 3g / min, after the heat preservation finishes, cool down to room temperature naturally, and make palm activated carbon fiber.

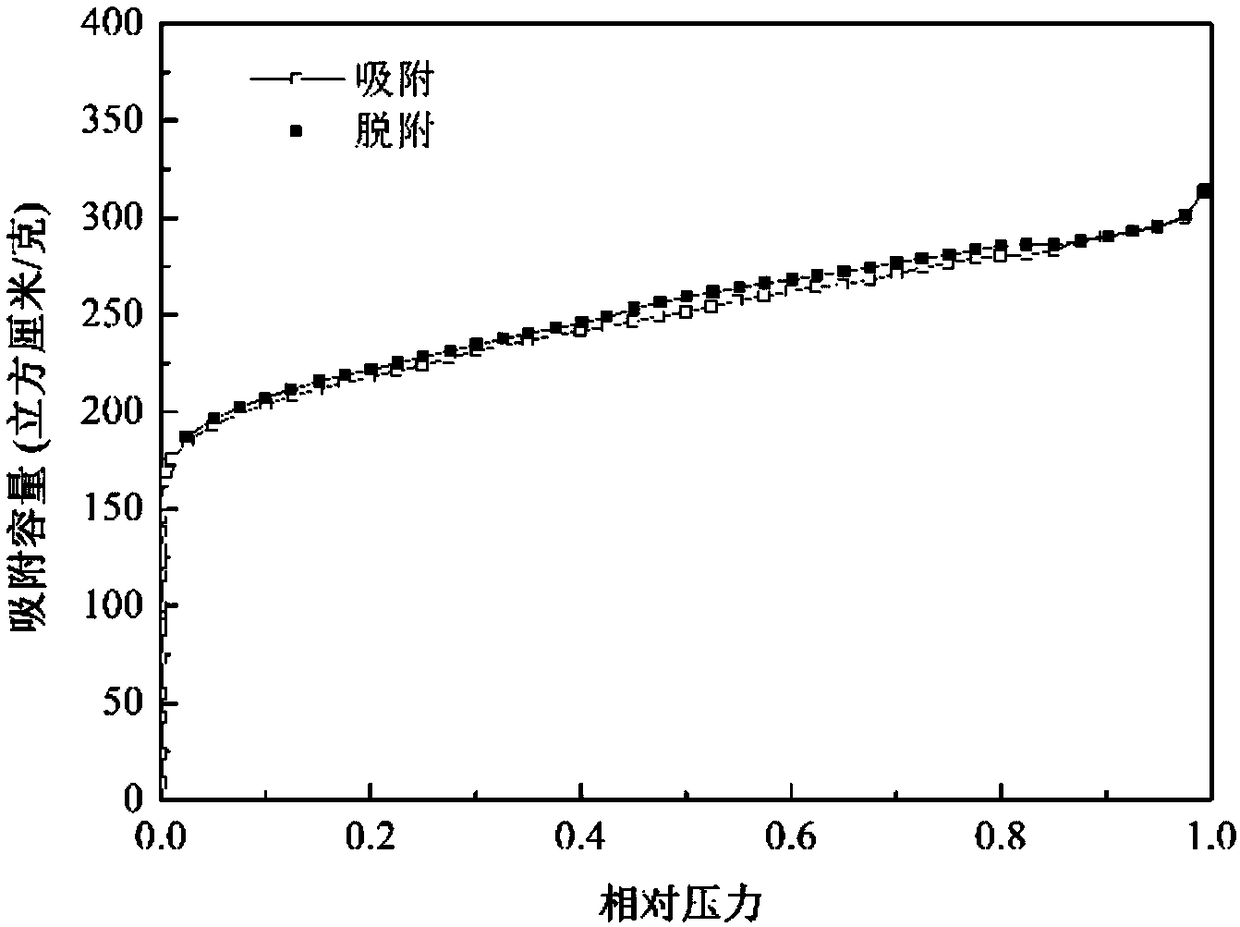

[0032] Adopt the Autosorb-1 nitrogen adsorption instrument that Quantachrome instrument company provides, the nitrogen adsorption-desorption curve figure that obtains (see figure 1 ), the specific surface area of the palm activated carbon fiber that adopts multi-point BET method ...

Embodiment 2

[0034] Present embodiment provides a kind of preparation of palm activated carbon fiber, comprising:

[0035] (1) Wash the palm fiber with distilled water, remove the surface dust, and then put it in a constant temperature blast drying oven at 103±2°C for 24 hours;

[0036] (2) Heat the cleaned and dried palm fiber from room temperature to 800°C at a heating rate of 4°C / min, and keep it at 800°C for 20 minutes. The whole process is in a nitrogen gas atmosphere, and the flow rate of nitrogen gas is 200mL / min, feed water vapor while keeping warm, the water vapor flow rate is 3g / min, after the heat preservation finishes, cool down to room temperature naturally, and make palm activated carbon fiber.

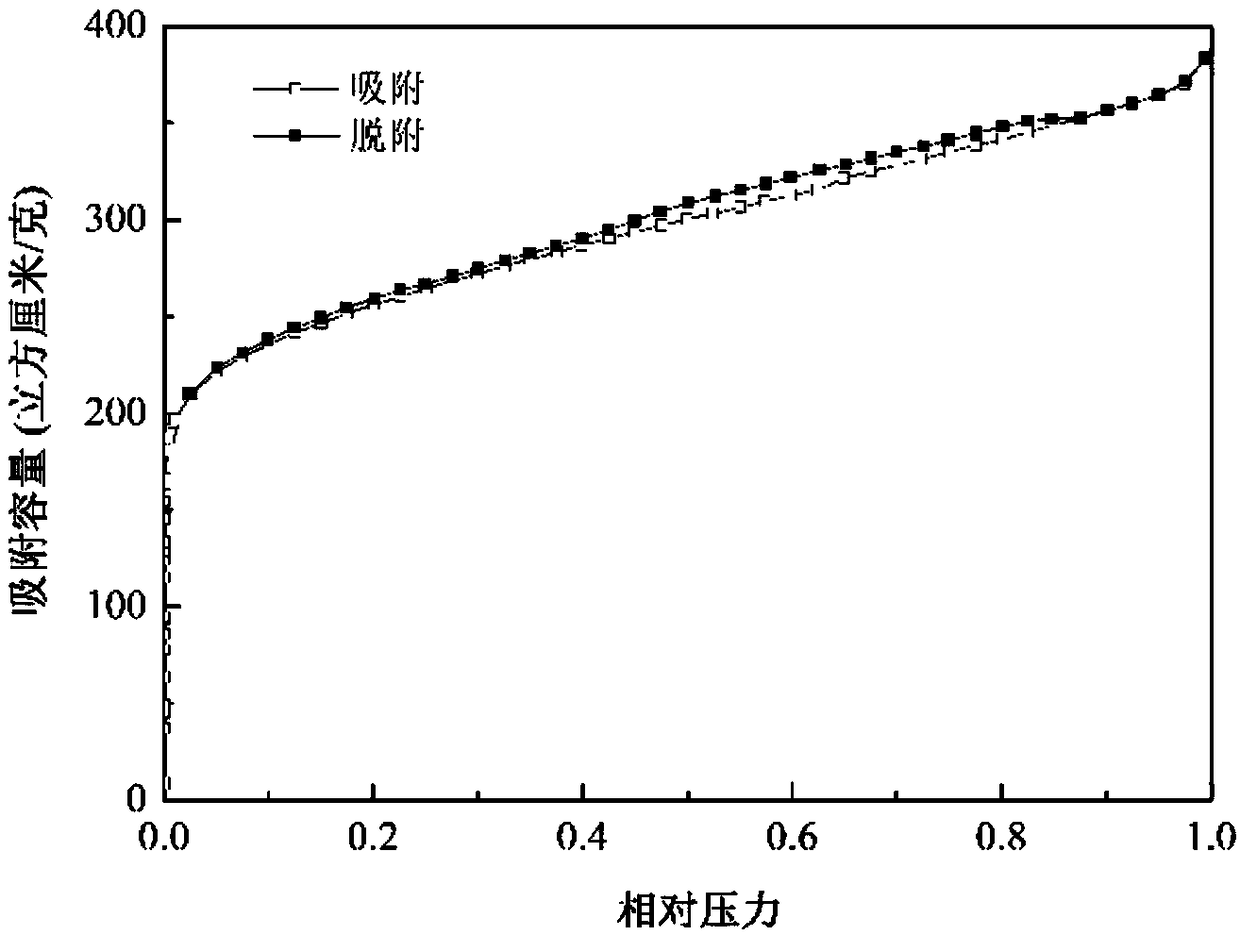

[0037] Adopt the Autosorb-1 nitrogen adsorption instrument that Quantachrome instrument company provides, the nitrogen adsorption-desorption curve figure that obtains (see figure 2 ), the specific surface area of the palm activated carbon fiber that adopts multi-point BET method...

Embodiment 3

[0039]Present embodiment provides a kind of preparation of palm activated carbon fiber, comprising:

[0040] (1) Wash the palm fiber with distilled water, remove the surface dust, and then put it in a constant temperature blast drying oven at 103±2°C for 24 hours;

[0041] (2) Heat the cleaned and dried palm fiber from room temperature to 800°C at a heating rate of 4°C / min, and keep it at 800°C for 40 minutes. The whole process is in a nitrogen gas atmosphere, and the flow rate of nitrogen gas is 200mL / min, feed water vapor while keeping warm, the water vapor flow rate is 3g / min, after the heat preservation finishes, cool down to room temperature naturally, and make palm activated carbon fiber.

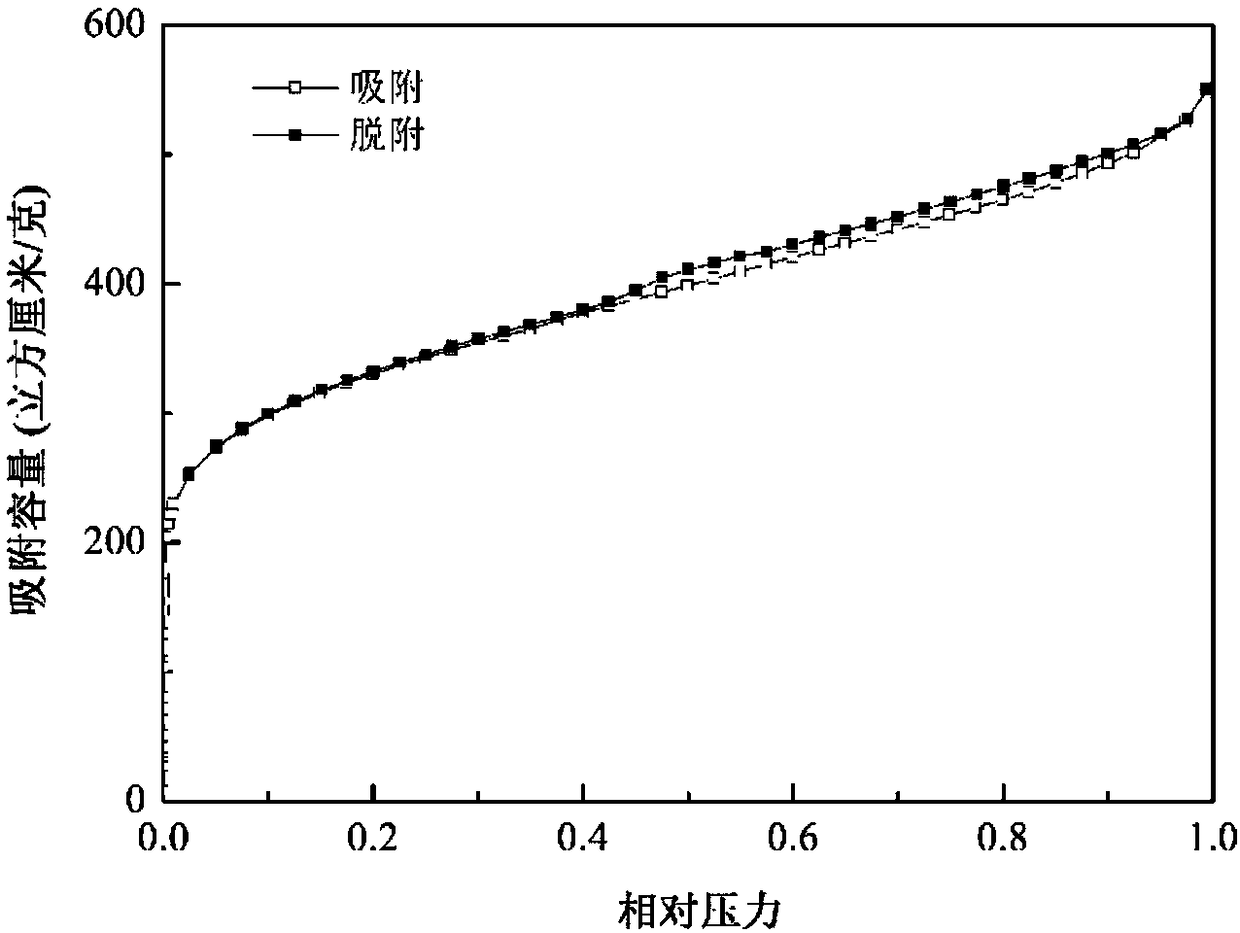

[0042] Adopt the Autosorb-1 nitrogen adsorption instrument that Quantachrome instrument company provides, the nitrogen adsorption-desorption curve figure that obtains (see image 3 ), the specific surface area of the palm activated carbon fiber that adopts multi-point BET method t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com