Gingko compound grain and preparation method thereof

A compound grain and ginkgo technology, which is applied in the field of food processing, can solve the problems of difficult detoxification, damage to the nutritional content of ginkgo fruit, limit the application and medicinal value of ginkgo fruit, and achieve the effect of enhancing the beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

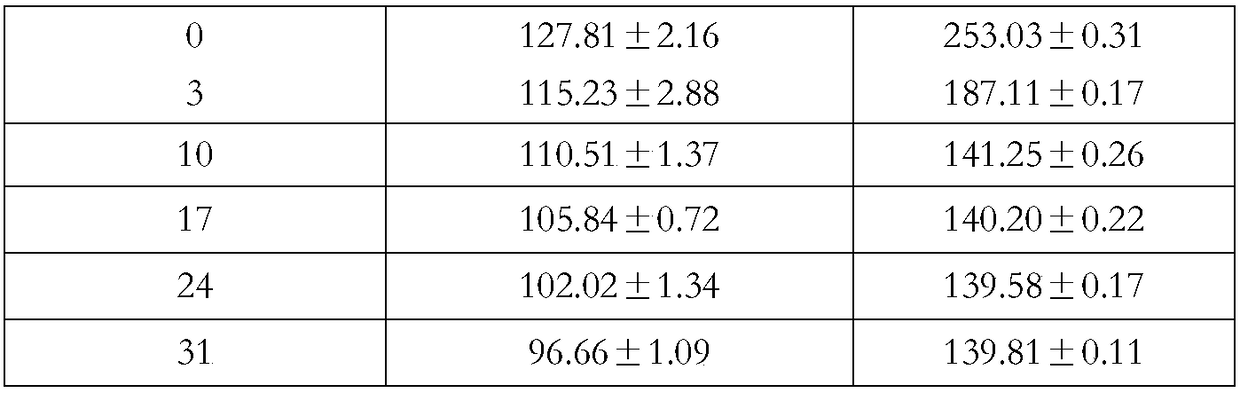

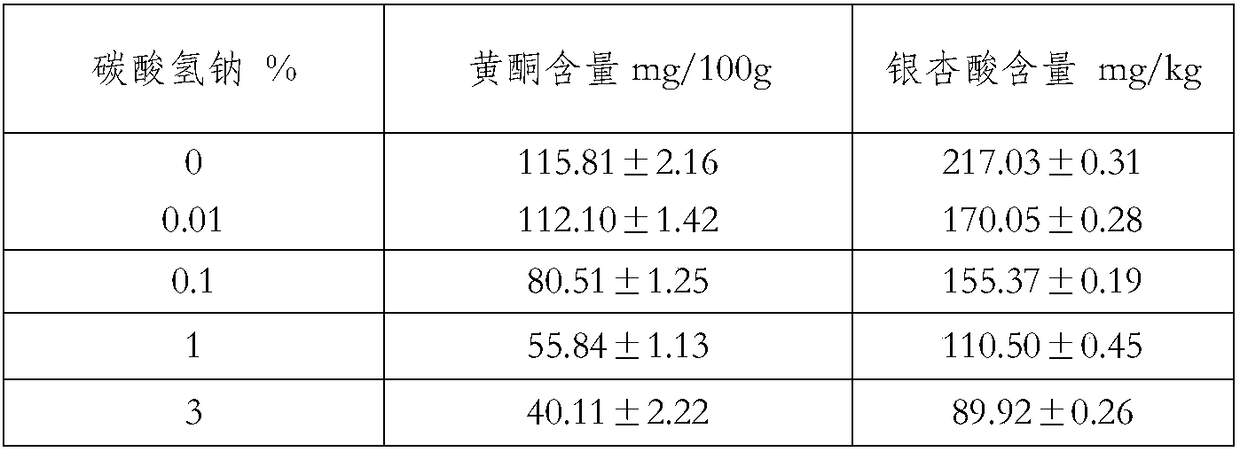

Embodiment 1

[0021] First, shell the ginkgo fruit with a sheller, crush it with a beater, add it to an enzymatic hydrolysis tank with stirring, add water twice the weight of the shelled ginkgo fruit, and stir to form a suspension. The temperature of the ginkgo fruit suspension is raised to 20° C., and the compound bacteria and enzyme preparation are added at the same time. The total amount of the compound bacteria and enzyme preparation is 0.1% of the mass of the shelled ginkgo fruit, and the temperature is kept for 24 hours. The composition of complex bacteria and enzyme preparation is two kinds of Saccharomyces cerevisiae, Lactobacillus plantarum, amylase, and sodium bicarbonate. After fermentation, the suspension was dried by a tumble dryer, then pulverized into 40 meshes, and adjusted to 20% moisture in a mixer. Then enter the twin-screw extruder for extrusion, the screw speed is 100r / min, and the barrel outlet temperature is 180°C. The extruded material was dried and crushed to 80 me...

Embodiment 2

[0023] First, shell the ginkgo fruit with a sheller, crush it with a beater, add it to an enzymatic hydrolysis tank with stirring, add water twice the weight of the shelled ginkgo fruit, and stir to form a suspension. The temperature of the ginkgo fruit suspension was raised to 50° C., and the compound bacteria and enzyme preparation were added at the same time. The total amount of the compound bacteria and enzyme preparation was 5% of the mass of the shelled ginkgo fruit, and kept for 3 hours. The composite bacteria and the enzyme preparation are composed of saccharomyces cerevisiae, lactobacillus plantarum, amylase and sodium bicarbonate. The post-fermentation suspension was dried by a tumble dryer, then pulverized into 40 meshes, and adjusted to 30% moisture in a mixer. Then enter the twin-screw extruder for extrusion, the screw speed is 200r / min, and the barrel outlet temperature is 100°C. The extruded material is dried and crushed to 80 mesh. Ginkgo powder and 80 mesh ri...

Embodiment 3

[0025] First, shell the ginkgo fruit with a sheller, crush it with a beater, add it to an enzymatic hydrolysis tank with stirring, add water twice the weight of the shelled ginkgo fruit, and stir to form a suspension. The temperature of the ginkgo fruit suspension is raised to 30° C., and the compound bacteria and enzyme preparation are added at the same time. The total amount of the compound bacteria and enzyme preparation is 2% of the mass of the shelled ginkgo fruit, and the temperature is kept for 10 hours. The composite bacteria and the enzyme preparation are composed of two or four kinds of Saccharomyces cerevisiae, Lactobacillus plantarum, amylase, and sodium bicarbonate. The post-fermentation suspension was dried by a tumble dryer, then pulverized into 60 meshes, and then adjusted to 30% moisture in a mixer. Then enter the twin-screw extruder for extrusion, the screw speed is 150r / min, and the barrel outlet temperature is 130°C. The extruded material is dried and crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com