Water-based coating composition

A technology of water-based coatings and compositions, which is applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc. It can solve the problems of water-based coating compositions such as gloss stability and insufficient weather resistance of the smooth coating film, and achieve storage stability. Excellent, excellent corrosion resistance, less change in gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

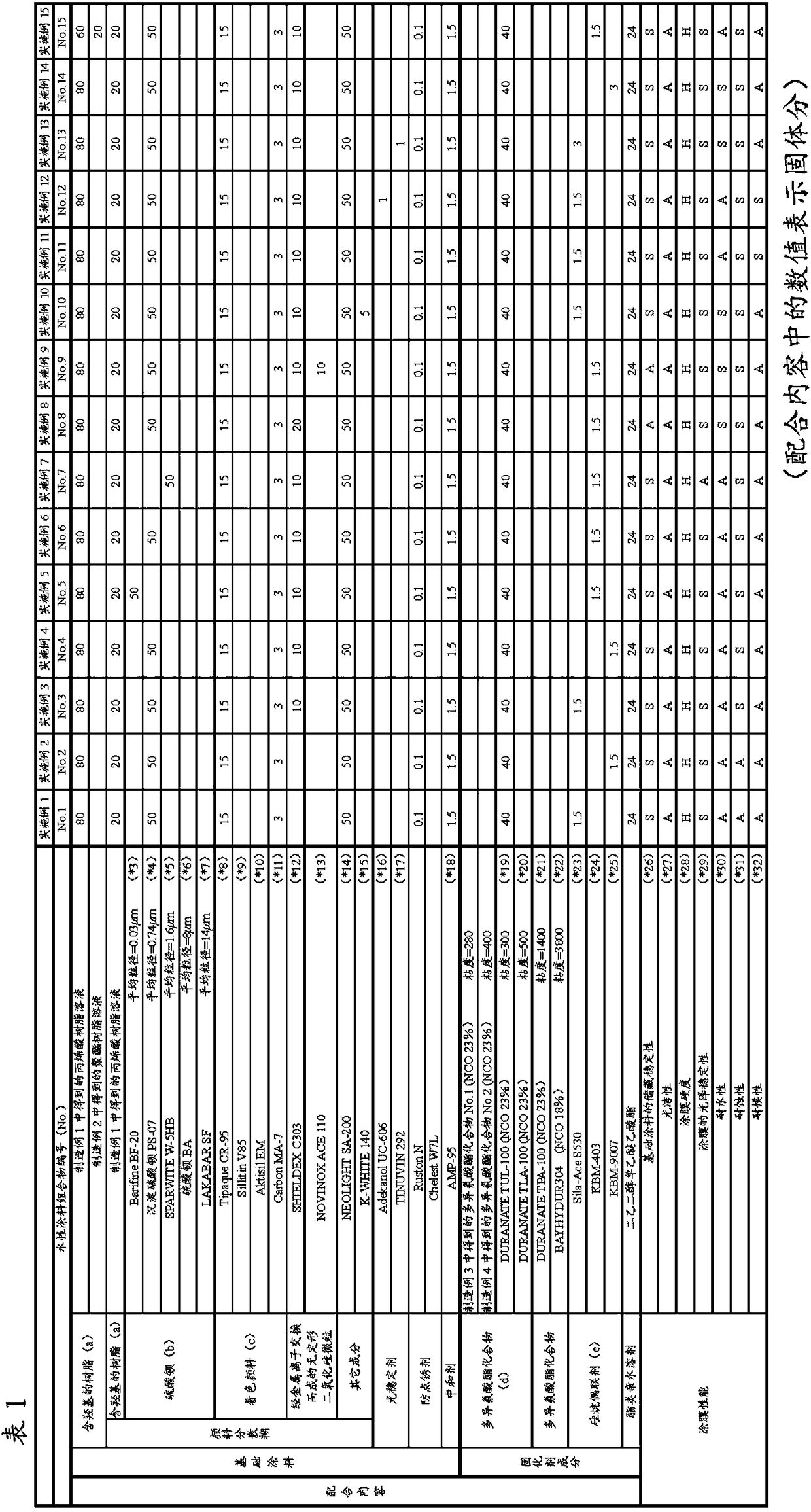

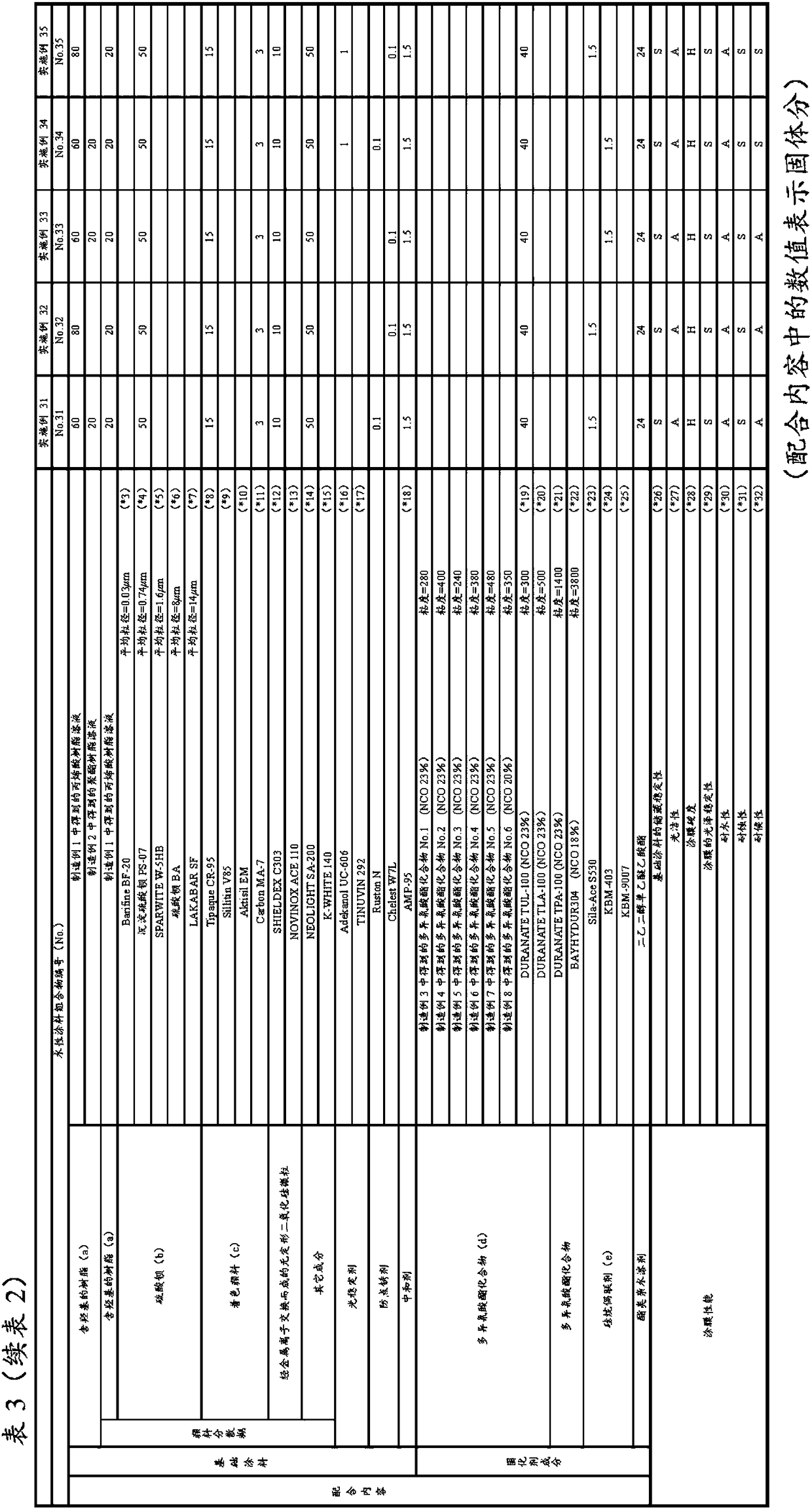

Examples

manufacture example 1

[0112] Production example 1: Production example of acrylic resin solution

[0113] 368.6 parts of ethylene glycol monobutyl ether was charged into a 2-liter four-necked flask equipped with a stirrer, a thermometer, a reflux tube, and a nitrogen introduction tube, and after replacing with nitrogen, the mixture was kept at 85° C. while stirring.

[0114] In 3 hours, 130 parts of styrene, 144 parts of methyl methacrylate, 150 parts of n-butyl methacrylate, 250 parts of isobutyl methacrylate, 200 parts of n-butyl acrylate, 2 - A mixture of 426 parts of hydroxyethyl ester, 50 parts of acrylic acid, and 19.5 parts of 2,2'-azobis(2,4-dimethylvaleronitrile), and after the dropwise addition was completed, it was further kept at 85° C. for 1 hour, Then, a mixture of 65 parts of ethylene glycol monobutyl ether and 6.5 parts of 2,2'-azobis(2,4-dimethylvaleronitrile) was added dropwise over 1 hour. After completion of the dropwise addition, the temperature was maintained at 85°C for 1 hou...

manufacture example 2

[0115] Production example 2: Production example of polyester resin solution

[0116] In a reaction vessel equipped with a stirrer, a thermometer, a reflux pipe, a nitrogen introduction pipe, a rectification tower, and a water separator, 17 parts of trimethylolpropane, 1,6-hexanediol, and 21 parts, 15 parts of adipic acid, 29 parts of phthalic anhydride and 12 parts of Cardura E10P (manufactured by HEXION Specialty Chemicals, trade name, synthetic hyperbranched saturated fatty acid glycidyl ester) carry out condensation reaction, make resin acid value reach After 1.0 mgKOH / g or less, the toluene was solvent-removed under reduced pressure, and the reaction temperature was kept at 170°C.

[0117]Add 6 parts of trimellitic anhydride to the reaction product, make it react at 170°C, add dipropylene glycol monomethyl ether for 30 minutes, add dipropylene glycol monomethyl ether and cool to 85°C, neutralize with dimethylethanolamine, then form water with water A dispersion liquid was...

manufacture example 3

[0118] Production Example 3: Production Example of Polyisocyanate Compound No.1 Solution

[0119] A four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen blowing pipe, and a dropping funnel was set as a nitrogen atmosphere, and 600 parts of hexamethylene diisocyanate and 2.5 parts of isobutanol were added, and the The temperature inside the reactor was maintained at 80°C for 2 hours. Then, 0.5 parts of a solution obtained by diluting the isocyanuration catalyst trimethyl-2-methyl-2-hydroxyethylammonium hydroxide to a concentration of 5% by mass with isobutanol was added to perform isocyanuration. After cyanurate reaction, 0.06 parts of phosphoric acid 85% aqueous solution was added to terminate the reaction.

[0120] Then, the reaction liquid was further kept at 160° C. for 1 hour to generate polyisocyanate. After cooling the reaction liquid to room temperature and filtering, unreacted hexamethylene diisocyanate was removed using a thin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com