Grout coating and preparation method thereof

A paint and grout technology, applied in the direction of coating, etc., can solve the problems of paint film gloss reduction, poor scrub resistance, large proportion, etc., achieve high gloss stability, good polishing effect, and increase the effect of scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

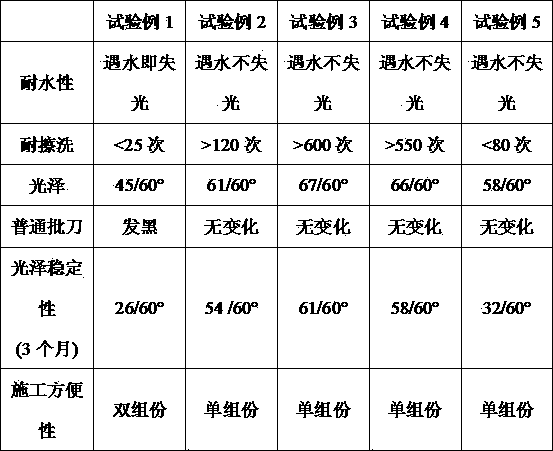

Examples

Embodiment

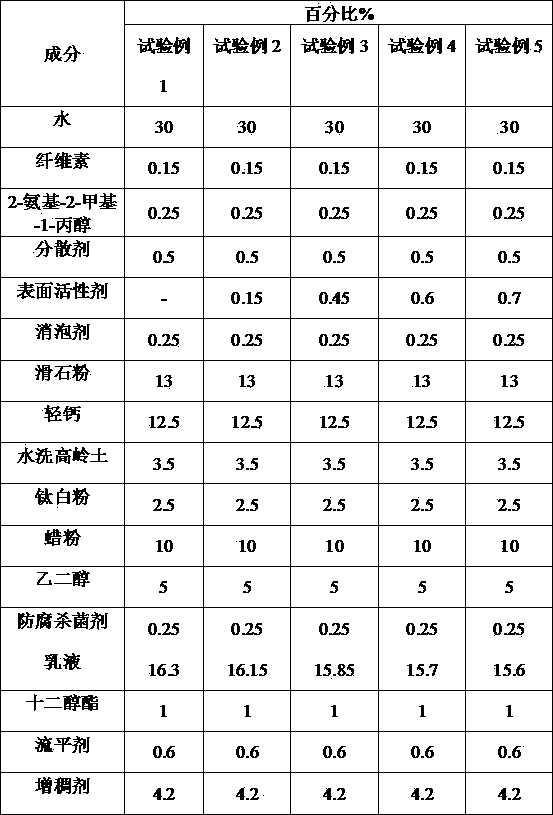

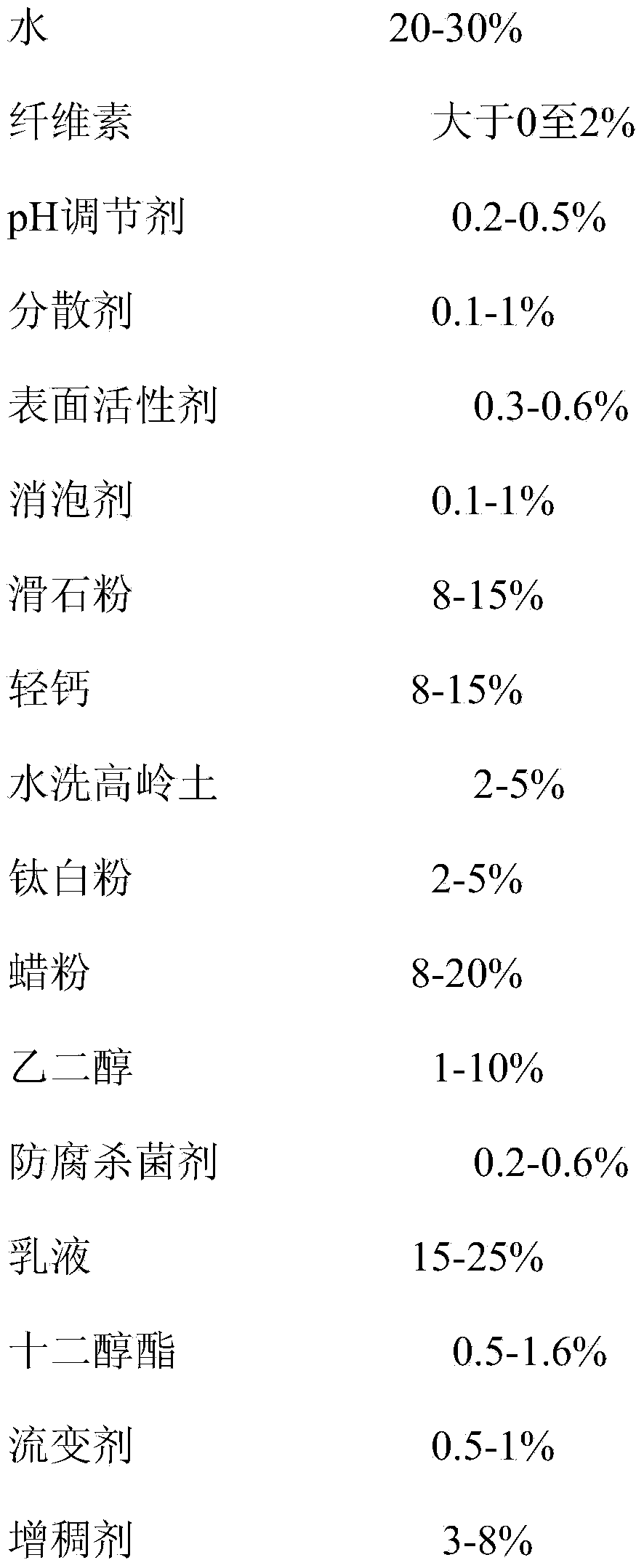

[0065] Element percentage% water 20 Cellulose 2 2-Amino-2-methyl-1-propanol 0.5 Dispersant 1 Surfactant 0.6 Defoamer 1 talcum powder 15 light calcium 15 Washed Kaolin 5 Titanium dioxide 5 wax powder 11 Ethylene glycol 1 Antiseptics 0.6 lotion 15 lauryl alcohol ester 0.5 leveling agent 0.5 thickener 5.3

[0066] Method: Put the formula amount of water in the disperser, set the speed at 800 rpm, slowly add cellulose, pre-dissolve for 5 minutes, add pH regulator, dissolve until transparent and free of particles, then add dispersant and defoamer , Surfactant, stir for 3 minutes, then add talcum powder, kaolin, titanium dioxide, wax powder in turn, adjust the speed of the disperser to 4500 rpm, disperse at high speed for 15 minutes, check the fineness, after the fineness is ≤ 50μm Adjust the rotation speed to 1000 rpm, slowly add other ingredients in the formula one by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com