A kind of liquid glass composite proton exchange membrane for fuel cell and its preparation method

A proton exchange membrane and liquid glass technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of electrolyte membrane corrosion, holes, and short service life, and achieve the effect of preventing oxidation corrosion and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

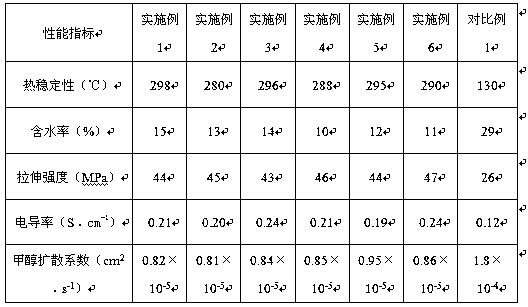

Examples

Embodiment 1

[0029] A method for preparing a liquid glass composite proton exchange membrane for a fuel cell, the steps are as follows:

[0030] a. Take the sulfonated aromatic polymer, freeze it in liquid nitrogen for 12 minutes, and use a supersonic impact plate jet mill at an air velocity of 5m 3 / min and the rotating speed of the classifier is 2600r / min to carry out the miniaturization treatment, the miniaturization treatment time is 20min, and the fine powder with a particle size of 1-100nm is obtained; the sulfonated aromatic polymer is sulfonated polyetheretherketone, sulfonated At least one of sulfonated polyether sulfone and sulfonated polyarylether nitrile ketone;

[0031] b. Add the fine powder obtained in step a into the silica sol, add a dispersant and a solvent, and use a magnetic stirrer to stir to obtain a jelly. The stirring rate is 250r / min, and the stirring time is 2h; the dispersant is three At least one of sodium polyphosphate, sodium hexametaphosphate or sodium pyrop...

Embodiment 2

[0041] A method for preparing a liquid glass composite proton exchange membrane for a fuel cell, the steps are as follows:

[0042] a. Take the sulfonated aromatic polymer, freeze it in liquid nitrogen for 10 minutes, and use a supersonic impact plate jet mill at an air velocity of 10m 3 / min and the rotating speed of the classifier is 2500r / min to carry out the miniaturization treatment, the miniaturization treatment time is 30min, and the fine powder with a particle size of 1-100nm is obtained; the sulfonated aromatic polymer is sulfonated polyether ether ketone, sulfonated At least one of sulfonated polyether sulfone and sulfonated polyarylether nitrile ketone;

[0043] b. Add the fine powder obtained in step a into the silica sol, add a dispersant and a solvent, and use a magnetic stirrer to stir to obtain a jelly. The stirring rate is 200r / min, and the stirring time is 3h; the dispersant is three At least one of sodium polyphosphate, sodium hexametaphosphate or sodium py...

Embodiment 3

[0048] A method for preparing a liquid glass composite proton exchange membrane for a fuel cell, the steps are as follows:

[0049] a. Take the sulfonated aromatic polymer, freeze it in liquid nitrogen for 30 minutes, and use a supersonic impact plate jet mill at an air velocity of 3m 3 / min and the rotating speed of the classifier is 2600r / min to carry out the micronization treatment, the micronization treatment time is 18min, and the fine powder with a particle size of 1-100nm is obtained; the sulfonated aromatic polymer is sulfonated polyether ether ketone, sulfonated At least one of sulfonated polyether sulfone and sulfonated polyarylether nitrile ketone;

[0050] b. Add the fine powder obtained in step a into the silica sol, add a dispersant and a solvent, and use a magnetic stirrer to stir to obtain a jelly. The stirring rate is 200r / min, and the stirring time is 3h; the dispersant is three At least one of sodium polyphosphate, sodium hexametaphosphate or sodium pyropho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com