A method for producing hydrogen by using sludge thermochemical reaction

A thermochemical reaction and sludge technology, applied in the field of environmental protection and comprehensive utilization of resources, can solve the problems of long time-consuming hydrogen production process and complicated operation process, and achieve the effects of easy acquisition, simple operation and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of dry sludge

[0033] Take some activated sludge obtained from the secondary sedimentation tank, put it in a constant temperature blast drying oven at 105°C and dry it for 12 hours, then crush the dry sludge with a pulverizer, and pass through an 80-mesh sieve to obtain sieved dry sludge particles.

[0034] (2) Mix the reactants and build the reaction system

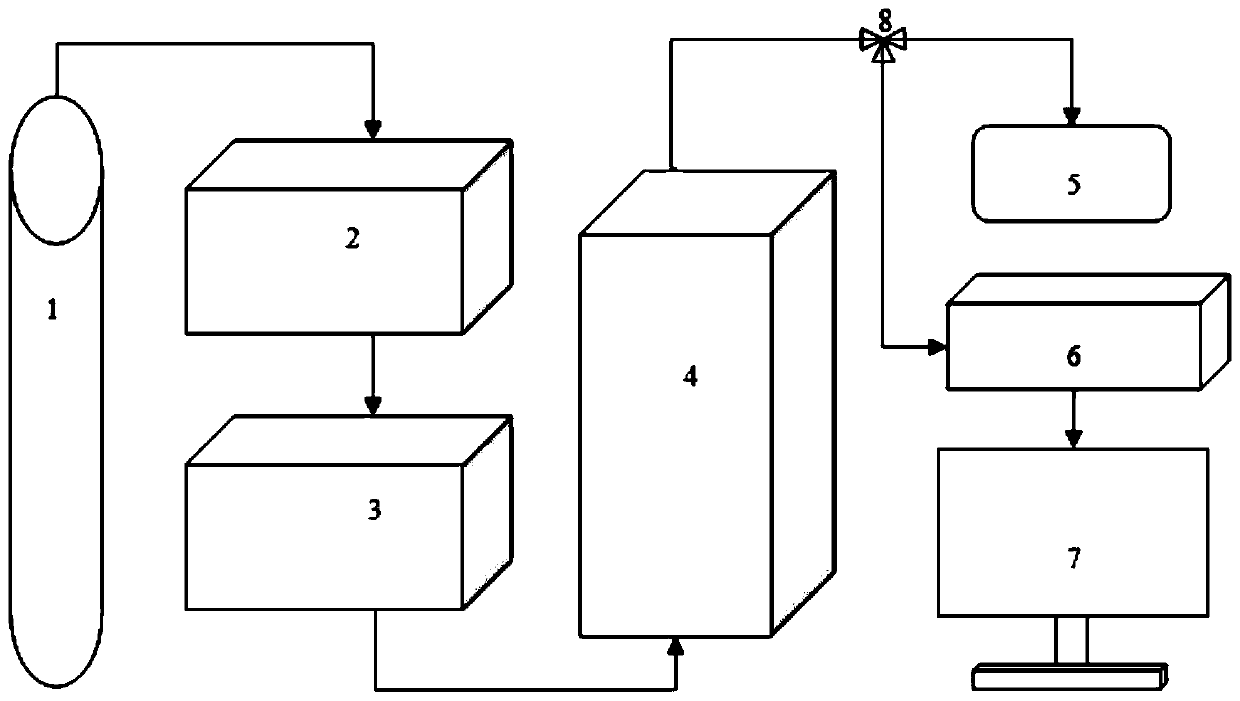

[0035] Take 1g of dry sludge and 3g of sodium hydroxide and place them in an alumina crucible, mechanically stir evenly, seal the alumina crucible in a high-temperature-resistant quartz tube, and then place it in the tube furnace 3, and follow the attached figure 1 Build a responsive system.

[0036] The structure of the reaction system is as follows: the high-purity nitrogen storage tank 1 is connected to the gas inlet of the tube furnace 3, and a mass flow controller 2 is arranged on the connecting pipeline. Mud and sodium hydroxide solid aluminum oxide porcelain boat, the outlet of the tube f...

Embodiment 2

[0042] (1) Preparation of dry sludge

[0043] Take some activated sludge obtained from the secondary sedimentation tank, put it in a constant temperature blast drying oven at 105°C and dry it for 12 hours, then crush the dry sludge with a pulverizer, and pass through an 80-mesh sieve to obtain sieved dry sludge particles.

[0044] (2) Mix the reactants and build the reaction system

[0045]Take 0.5g of dry sludge and 1.5g of sodium hydroxide and place them in an alumina crucible, stir them evenly, seal the alumina crucible in a high-temperature resistant quartz tube, and then place it in a tube furnace. figure 1 Build a responsive system.

[0046] (3) Purify the system and start the reaction

[0047] Feed nitrogen into the reaction system, the nitrogen mass flow is controlled by a mass flow controller, which is 70mL / min, until the nitrogen concentration of the display screen connected to the micro-gas chromatograph shows 100%, close the attached figure 1 Open the gas path l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com