Composite environment-friendly rubber material and preparation method thereof

An environmentally friendly rubber and rubber technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor reflectivity, brightness and impact toughness, achieve simple formula and process, low production cost, and improve the performance of harsh environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

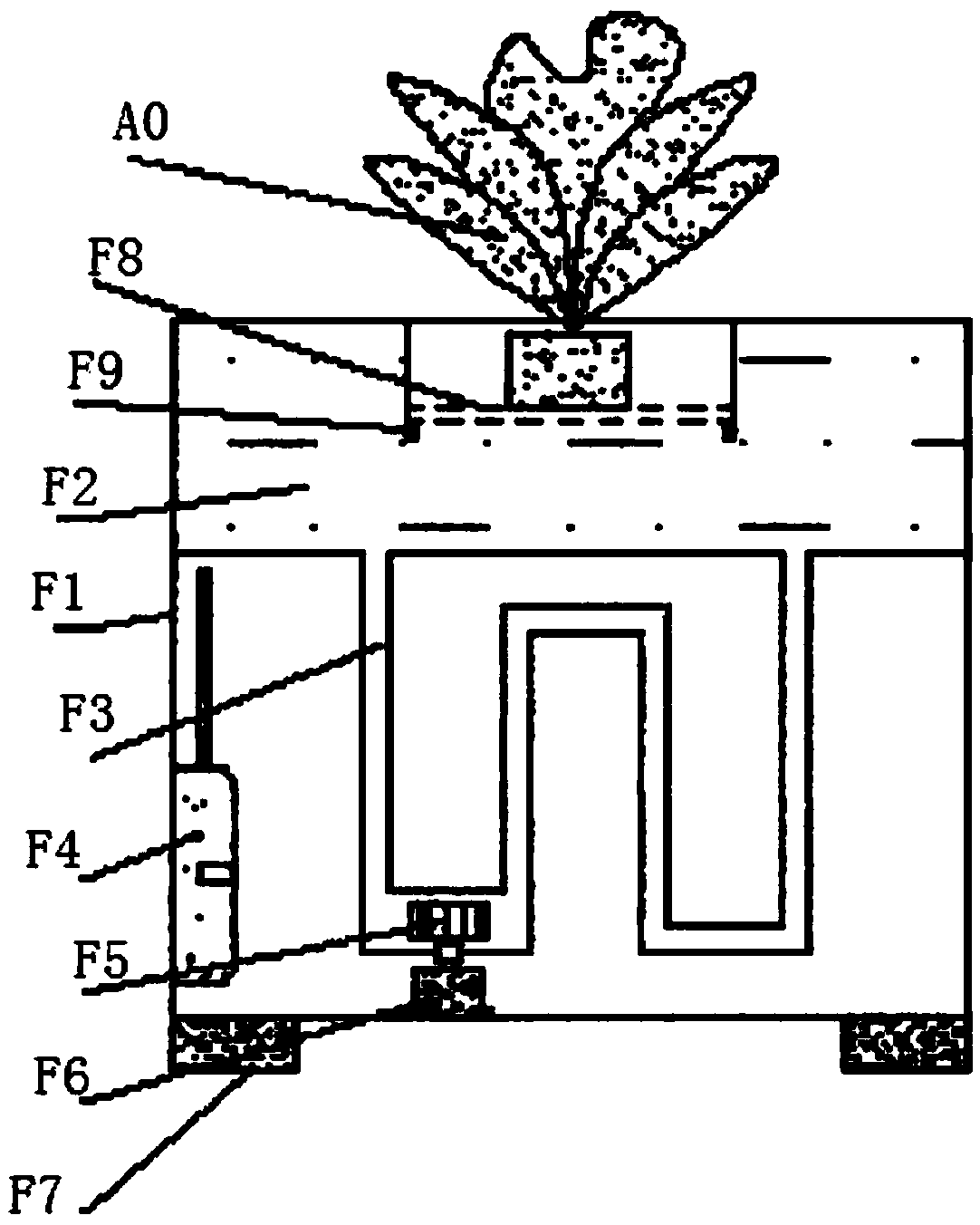

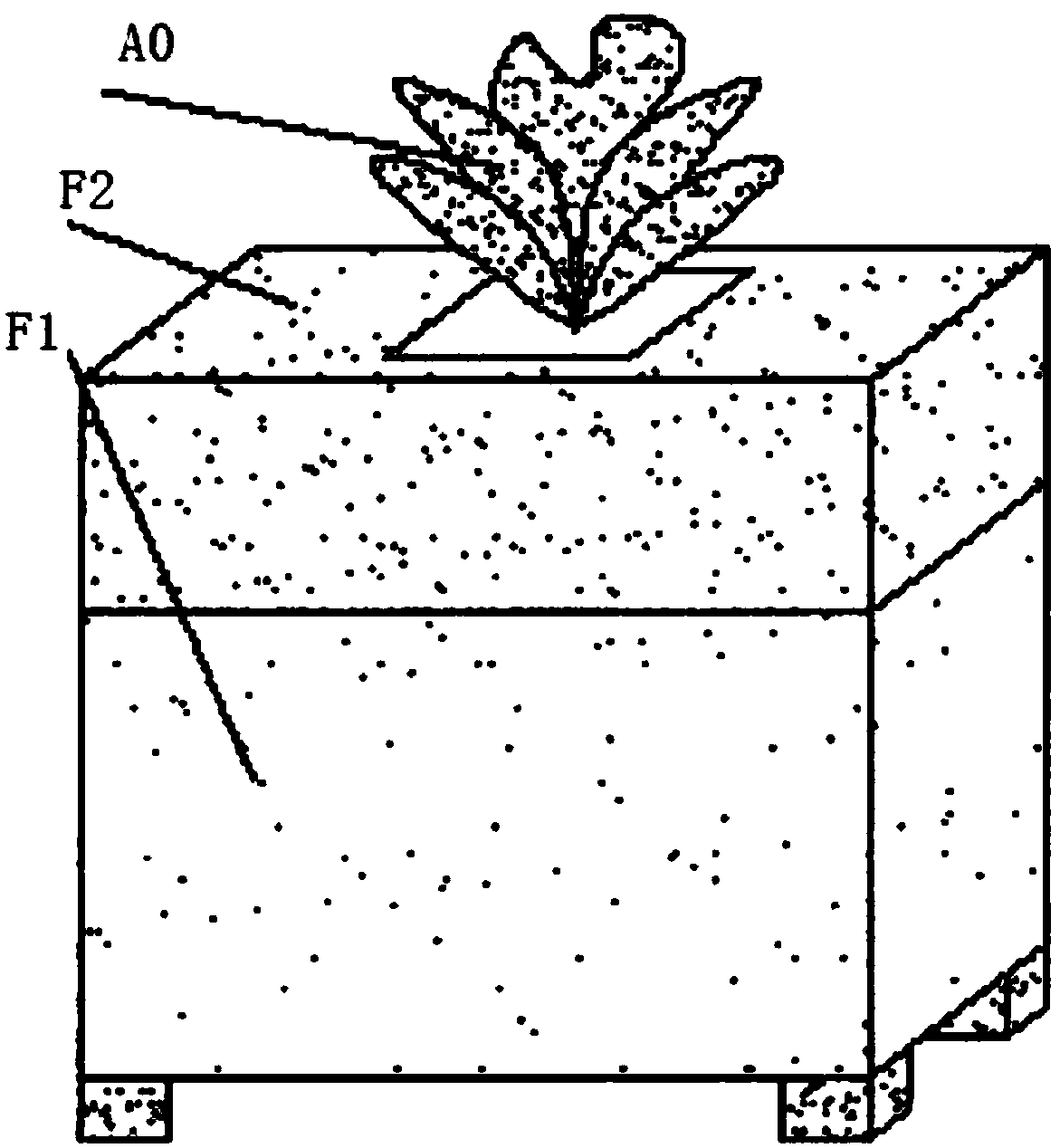

[0040] Such as Figure 1-Figure 2 As shown, the composite environment-friendly rubber material, calculated in parts by weight, includes the following raw materials: 62 parts of coal gangue powder, 25 parts of methyl vinyl silicone rubber, 6 parts of nano clay, 6 parts of silane coupling agent, zinc oxide 0.9 parts, 0.4 parts of paraffin, 62 parts of carbon black, 0.2 parts of N-cyclohexyl-N-phenyl-p-phenylenediamine, 4 parts of pine tar, 0.7 parts of antioxidant mercaptobenzimidazole, 0.3 parts of potassium pyrrolidone carboxylate, 2 parts of damping additive, 1.5 parts of sulfur;

[0041] It also includes the following parts in terms of parts by weight: 84 parts of kaolin, 22 parts of diatomaceous earth, 4 parts of aluminum oxide, 1.2 parts of copper stearate, 1.6 parts of butyl benzyl phthalate, 1.2 parts of Sorbitan ester, 1.6 parts of polyoxyethylene abietic acid, 2 parts of polyvinyl acetate latex, 0.6 part of polyacrylate.

[0042] The preparation method of described c...

Embodiment 2

[0069] Such as Figure 1-Figure 2 As shown, the composite environment-friendly rubber material, calculated according to parts by weight, includes the following parts of raw materials: 65 parts of coal gangue powder, 30 parts of methyl vinyl silicone rubber, 10 parts of nano clay, 10 parts of silane coupling agent, zinc oxide 1.1 parts, 0.5 parts of paraffin, 66 parts of carbon black, 0.23 parts of N-cyclohexyl-N-phenyl-p-phenylenediamine, 5 parts of pine tar, 1.0 parts of antioxidant mercaptobenzimidazole, 0.35 parts of potassium pyrrolidone carboxylate, 2.25 parts of damping additive, 1.6 parts of sulfur;

[0070] It also includes the raw materials of the following parts in terms of parts by weight: 100 parts of kaolin, 24 parts of diatomaceous earth, 8 parts of aluminum oxide, 1.4 parts of copper stearate, 1.8 parts of butyl benzyl phthalate, 1.5 parts Sorbitan ester, 2.4 parts polyoxyethylene abietic acid, 2.8 parts polyvinyl acetate latex, 1.5 parts polyacrylate.

[0071...

Embodiment 3

[0098] Such as Figure 1-Figure 2 As shown, the composite environment-friendly rubber material, calculated according to parts by weight, includes the following parts of raw materials: 68 parts of coal gangue powder, 35 parts of methyl vinyl silicone rubber, 14 parts of nano clay, 14 parts of silane coupling agent, zinc oxide 1.3 parts, 0.6 parts of paraffin, 70 parts of carbon black, 0.26 parts of N-cyclohexyl-N-phenyl-p-phenylenediamine, 6 parts of pine tar, 1.3 parts of antioxidant mercaptobenzimidazole, 0.4 parts of potassium pyrrolidone carboxylate, 2.5 parts of damping additive, 1.7 parts of sulfur;

[0099] It also includes the raw materials of the following parts according to the calculation in parts by weight: 124 parts of kaolin, 26 parts of diatomaceous earth, 12 parts of aluminum oxide, 1.6 parts of copper stearate, 2.2 parts of butyl benzyl phthalate, 1.8 parts Sorbitan ester, 3.2 parts polyoxyethylene abietic acid, 3.6 parts polyvinyl acetate latex, 2.4 parts pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com