Novel floating-type wind turbine foundation platform based on tuning liquid-column vibration dampers

An oscillation damping, basic platform technology, applied in wind turbines, configurations for installing/supporting wind turbines, machines/engines, etc., can solve problems such as insufficient vibration resistance, increase stability, avoid resonance, and reduce vibration response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

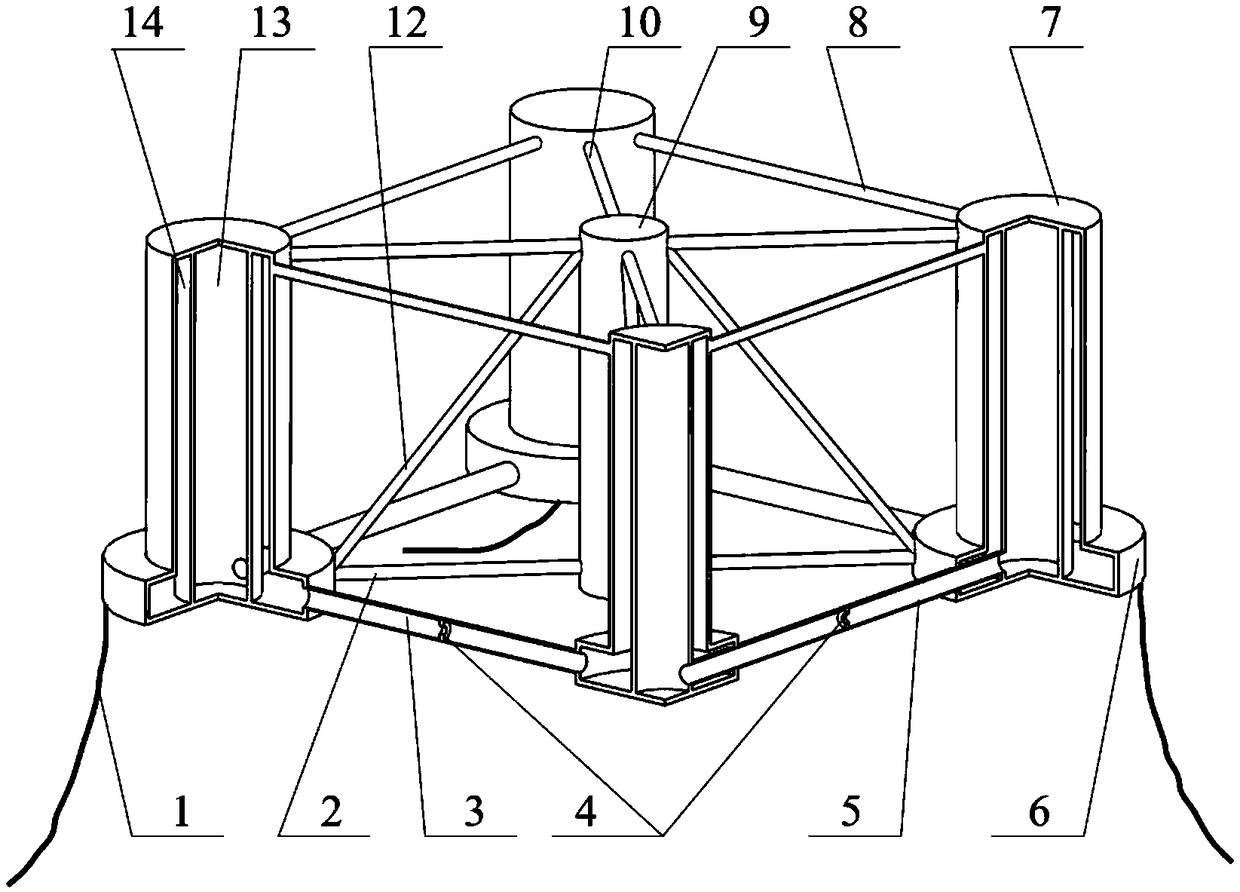

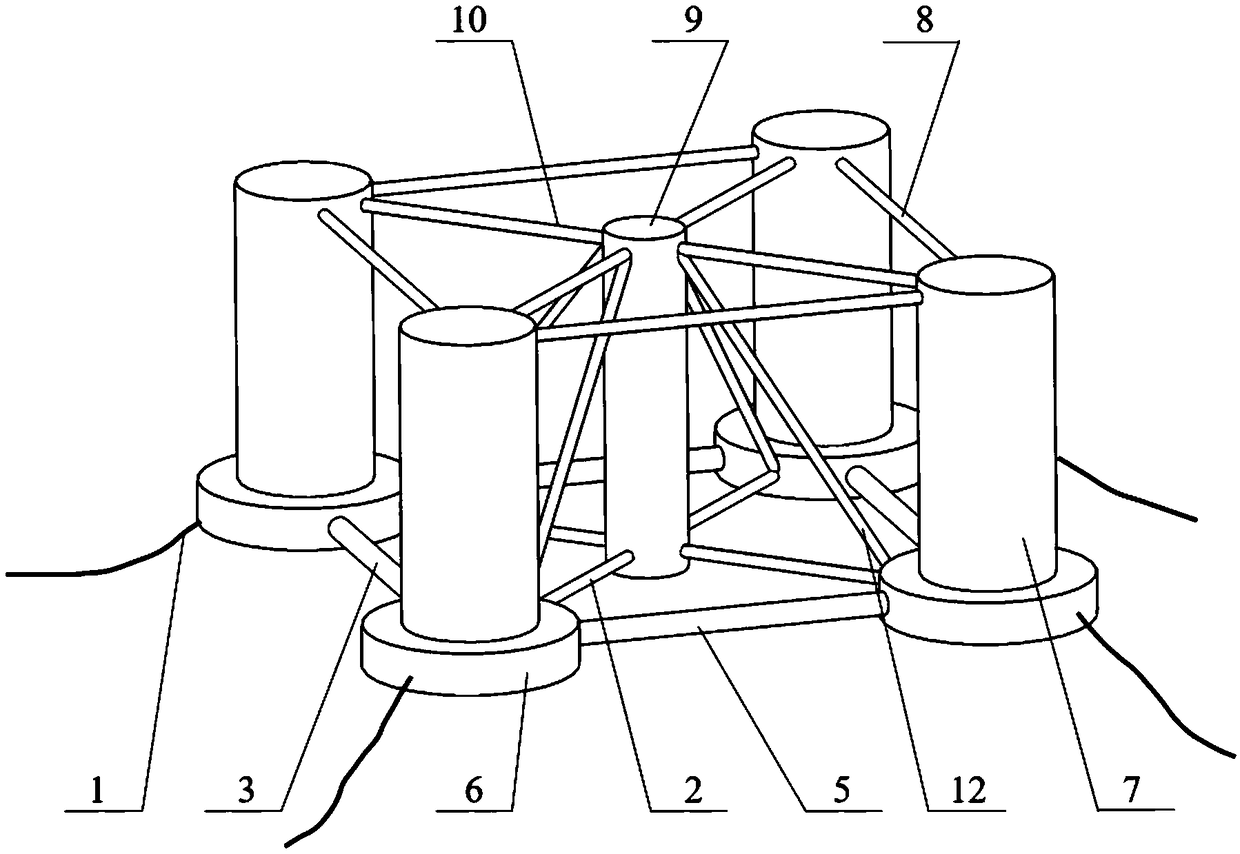

[0027] Such as figure 1 and figure 2 As shown, the specific implementation of the present invention includes a ballast tank, a truss structure and a mooring system. The ballast tank includes a central column 9 and four side columns, and the four side columns are arranged around the central column 9 respectively. The center of the square surrounded by two side columns, and the symmetrical two sides of the square surrounded by four side columns are parallel to the surge direction, and the fan is installed on the center column 9 top surfaces. Each side column comprises a main column 7 and a heave column 6, the heave column 6 is fixed on the bottom of the main column 7, the radial size of the heave column 6 is greater than the radial size of the main column 7, and the vertical axis of the heave column 6 The vertical dimension is much smaller than the vertical axial dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com