Recyclable epoxy resin and preparation method

A technology for recycling epoxy resin and epoxy resin, applied in the field of recyclable epoxy resin and preparation, can solve the problems of high condition requirements, low product rate, cumbersome process, etc., and achieves simple preparation process, good recovery, and alleviation of the environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

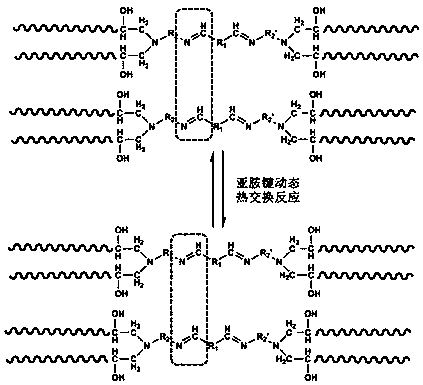

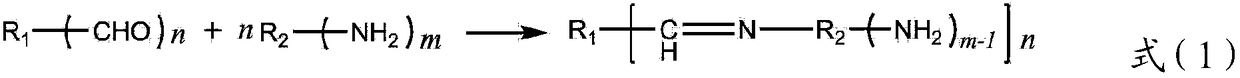

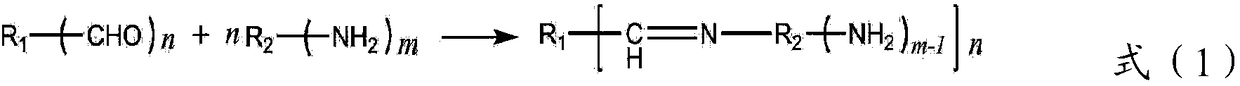

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Dissolve 15.0g ethylenediamine in 30ml methanol, stir at room temperature for 10min to obtain clear solution 1; weigh 16.5g terephthalaldehyde, dissolve in 15ml methanol, and ultrasonically treat for 5min at room temperature to obtain a clear solution 2. The solution 1 was heated to 40°C, and the solution 2 was slowly added dropwise to the rapidly stirring solution 1 with a constant pressure dropping funnel. After fully reacting for 12 hours, vacuum drying was performed to obtain an epoxy curing agent containing an imine bond structure. The structural formula is as follows:

[0032]

[0033] Step 2: Mix 100g of bisphenol A epoxy resin solution E51 with 28g of the above-prepared curing agent evenly, put it into a vacuum oven for vacuum deaeration for 30-50min, and pour the deaerated solution into a preheated stainless steel mold The epoxy resin was obtained after curing at 60° C. for 4 hours, post-curing at 80° C. for 4 hours, and cooling and demoulding.

[...

Embodiment 2

[0036] Step 1: Weigh 50g of diaminodiphenylmethane (DDM) and dissolve it in 60ml of methanol, stir at room temperature for 10min to obtain a clear solution 1; weigh 16.7g of terephthalaldehyde and dissolve it in 15ml of methanol, and ultrasonically treat it for 5min at room temperature , a clear solution 2 was obtained. The solution 1 was heated to 40°C, and the solution 2 was slowly added dropwise to the rapidly stirring solution 1 with a constant pressure dropping funnel. After fully reacting for 12 hours, vacuum drying was performed to obtain an epoxy curing agent containing an imine bond structure. The structural formula is as follows:

[0037]

[0038] Step 2: Mix 100g of bisphenol A epoxy resin solution E51 with 60g of the above-prepared curing agent evenly, put it in a vacuum oven for vacuum deaeration for 30-50min, and pour the deaerated solution into a preheated stainless steel mold The epoxy resin is obtained after curing at 60° C. for 4 hours, after curing at 10...

Embodiment 3

[0041] Step 1: Weigh 20g of ethylenediamine and dissolve it in 30ml of ethanol / dichloromethane solvent (volume ratio 8:2), stir at room temperature for 10min to obtain a clear solution 1; weigh 18g of trimesicaldehyde and dissolve it in 15ml of ethanol / In dichloromethane solvent, sonication was performed at room temperature for 5 min to obtain clear solution 2. The solution 1 was heated to 40°C, and the solution 2 was slowly added dropwise to the rapidly stirring solution 1 with a constant pressure dropping funnel. After fully reacting for 12 hours, vacuum drying was performed to obtain an epoxy curing agent containing an imine bond structure. The structural formula is as follows:

[0042]

[0043]Step 2: Mix 100g of bisphenol A epoxy resin solution E51 with 25g of the above-prepared curing agent evenly, put it in a vacuum oven for vacuum deaeration for 30-50min, and pour the deaerated solution into a preheated stainless steel mold The epoxy resin was obtained after curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com