A kind of reactive distillation prepares mtbe and its wastewater treatment method

A waste water treatment and reactive distillation technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, extraction water/sewage treatment, etc., can solve the problem that the use time is only 6-8 months, and achieve the source of raw materials Economy, increase efficiency, reduce COD effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

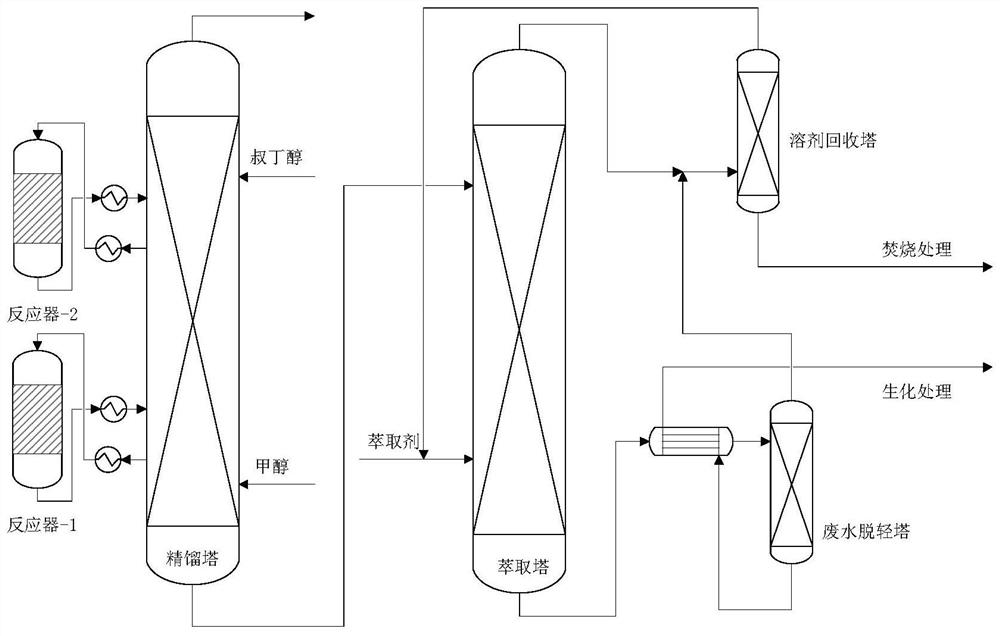

[0035] Such as figure 1 As shown, a rectification column with a theoretical plate number of 68 is used, with two side reactors connected by a heat exchanger and a compressor. Tert-butanol and methanol are respectively fed at the 27th and 57th theoretical plates of the rectification tower. Tert-butanol comes from the by-product of propylene oxide produced by the co-oxidation method, and there are about 1wt.% impurities in it, mainly isobutyric acid , Isobutanol, Isopropanol, etc. Reactor-2 draws a stream of material from the 35th theoretical plate of the rectification tower as a feed, and the discharge position is at the 20th theoretical plate; A stream of material is drawn from the plate as the feed, and the discharge position is at the 40th theoretical plate.

[0036] Both reactors use Rohm and Haas A-35 resin catalyst, the reactor pressure is 2MPa, and the temperature is 100°C. The feed mass ratio of tert-butanol to methanol is 1:1, and the residence time of materials in ...

Embodiment 2

[0041] On the basis of Example 1, the feed mass ratio of tert-butanol to methanol was changed to 3:4, and the other reaction and distillation parameters remained unchanged, D / F=0.86.

[0042] After the device was stabilized, sampling and analysis were carried out on the top of the rectification tower and the bottom of the tower. The water content in the bottom of the tower was 99.13wt%, tert-butanol was 0.51wt%, and methanol was 0.28wt%. The content of isobutene in the top was 8.46wt%, The content of MTBE is 65.17wt%, the content of methanol is 25.83wt%, the content of TBA is 0.31wt%, and the content of water is 0.10wt%. The conversion of TBA was 99.41%, the selectivity of isobutene was 16.94%, and the selectivity of MTBE was 82.79%.

[0043] The COD value of the produced wastewater is 35000mg / L, and the B / C value is 0.15. The extraction device is a multi-stage oil-water separator, the theoretical stage of the extraction device is 1, the mass ratio of the extraction agent to ...

Embodiment 3

[0046] On the basis of Example 1, the catalyst in Reactor-1 was replaced with H-ZSM-5, and the temperature of Reactor-1 was adjusted to 150° C. and the pressure to 3 MPa. All the other reaction and distillation parameters are unchanged, D / F=0.875.

[0047] After the device stabilized, sampling and analysis were carried out to the top of the rectification tower and the bottom of the tower. The water content in the bottom of the tower was 99.32wt%, tert-butanol was 0.19wt%, and methanol was 0.23wt%. The MTBE content was 57.17wt%, the methanol content was 35.93wt%, the TBA content was 0.09wt%, and the water content was 0.11wt%. The conversion rate of TBA is 99.80%, the selectivity of isobutene is 15.07%, and the selectivity of MTBE is 84.68%.

[0048] The COD value of the generated wastewater is 38000mg / L, and the B / C value is 0.13. The extraction device is a multi-stage mixing clarifier, the theoretical number of stages of the extraction device is 2, the mass ratio of the extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com