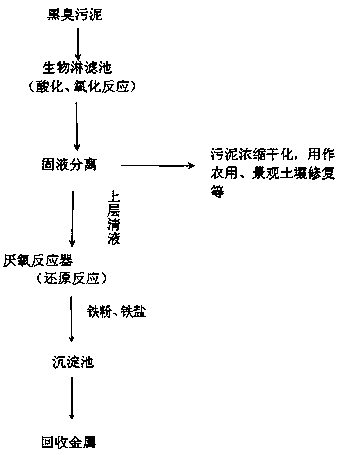

Black and odorous sludge treatment method

A treatment method and sludge technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the impact on the health and life of the surrounding residents, the destruction of the surrounding ecological environment, and the secondary pollution of the environment, etc. problems, achieve the effect of reducing heavy metal pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Throw the black and odorous sludge from a river dredging into the biological leaching tank, the sludge concentration is 10000mg / L, and the water content is 95%. During the leaching process, Desulfovibrio ( Desulfovibrio ) oxidizes sulfur compounds in the reduced state to form sulfate. The pH in the leaching tank is 3, the hydraulic retention time is 2 days, and the sludge age is 9 days.

[0023] (2) Introduce the supernatant from the leaching tank into the medium containing Desulfovibrio ( Desulfovibrio ) in the anaerobic fluidized bed, Desulfovibrio ( Desulfovibrio ) is added in an amount of 5% of the volume of the influent, and an appropriate amount of bagasse is added to make COD / SO 4 2- =0.6, the temperature of the anaerobic reactor is maintained at 18°C, the pH is maintained at 3, the oxidation-reduction potential (ORP)=-380mv, and sulfate radicals in the liquid phase are reduced to sulfur ions by sulfate-reducing bacteria.

[0024] (3) Lead the effluent...

Embodiment 2

[0026] (1) Put the black and odorous sludge from a certain lake into the bioleaching tank, the sludge concentration is 40000mg / L, and the water content is 90%. During the leaching process, Sulfobacillus ( Sulfobacillus ) oxidizes sulfur compounds in the reduced state to form sulfate. The pH in the leaching tank is 4.2, the hydraulic retention time is 4 days, and the sludge age is 30 days.

[0027] (2) Introduce the effluent from the leaching tank into the Desulfobacterium ) in the anaerobic filter tank, the amount of sulfate-reducing bacteria and influent water is 10% of the volume of influent water, and an appropriate amount of sucrose is added to make COD / SO 4 2- =2.4, the temperature of the anaerobic reactor is maintained at 35°C, the pH is maintained at 6, the oxidation-reduction potential (ORP)=-180mv, and the sulfate radical in the liquid phase is reduced to sulfur ion by sulfate-reducing bacteria.

[0028] (3) Lead the effluent from the anaerobic filter to the sedi...

Embodiment 3

[0030] (1) Throw the black and odorous sludge from a certain river dredging into the biological leaching tank, the sludge concentration is 80000mg / L, and the water content is 75%. During the leaching process, acidophilus ( Acid pHilium ) oxidizes sulfur compounds in the reduced state to form sulfate. The pH in the leaching tank is 6, the hydraulic retention time is 8 days, the sludge age is 5 days, and the sludge return flow is controlled so that the total sludge volume is 1 / 5 of the tank volume.

[0031] (2) Introduce the effluent from the leaching tank into the Desulfotomaculum ) In the upflow anaerobic sludge layer, the amount of sulfate-reducing bacteria added is 35% of the volume of the influent, and brewery wastewater is added to make the COD / SO 4 2- =4.8, the temperature of the anaerobic reactor is maintained at 70°C, the pH is maintained at 10, the oxidation-reduction potential (ORP)=0mv, and the sulfate radicals in the liquid phase are reduced to sulfur ions by su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com