Coding and printing line for lead storage batteries

A technology of lead-acid batteries and printing lines, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as low efficiency, achieve the effect of improving work efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

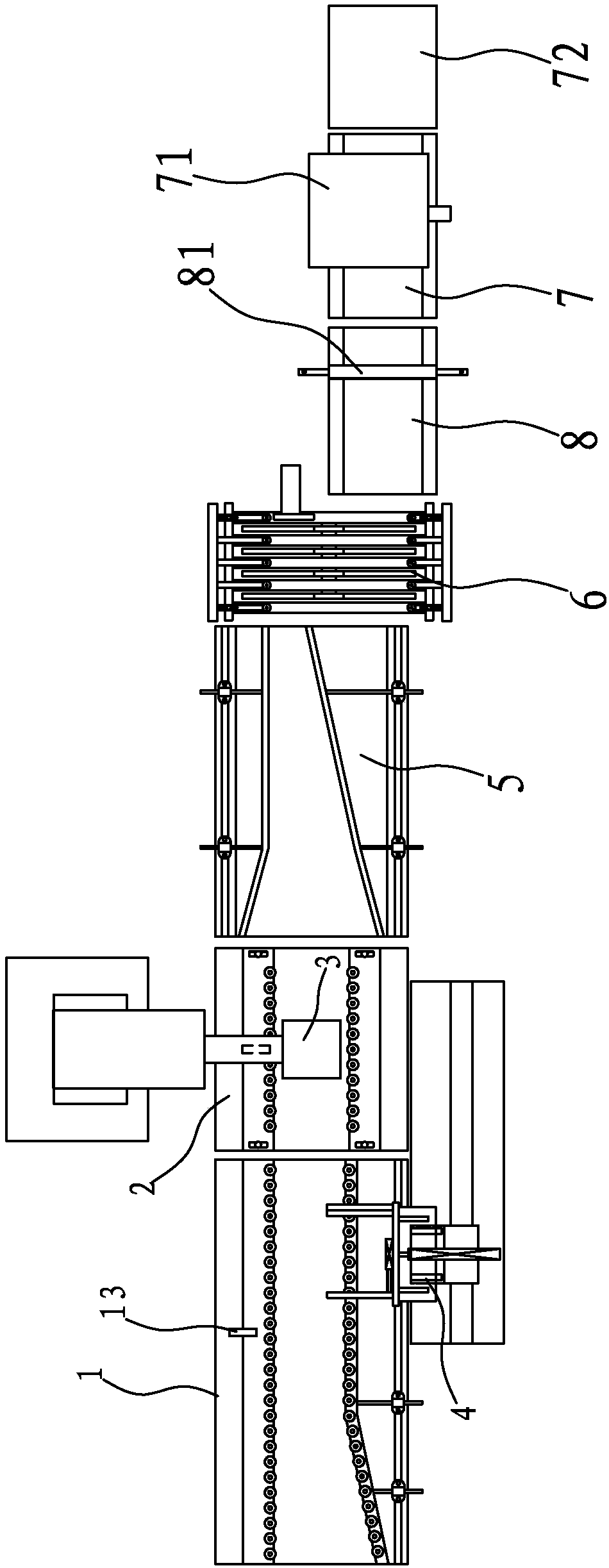

[0037] Such as figure 1 As shown, a lead-acid battery coding and printing line includes a laser coding line, a battery turning device 6 and a screen printing line connected in sequence.

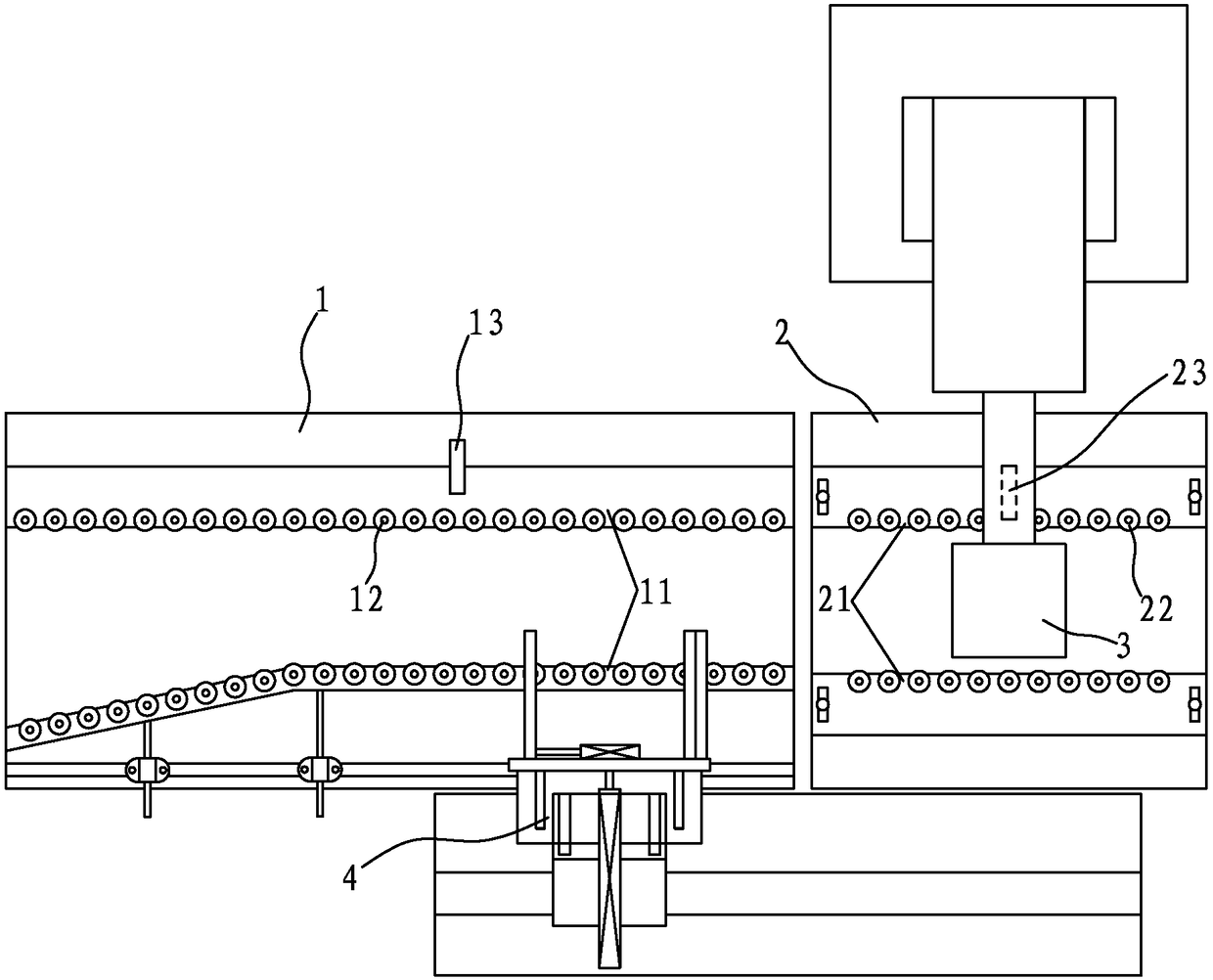

[0038] Such as figure 2 As shown, the laser coding line includes: a workbench 2 carrying batteries to be coded, and a laser coding device 3 is arranged above the workbench 2; a first conveyor belt 1 for conveying batteries at the same level as the workbench 2; The battery to be coded is picked up from the first conveyor belt 1 and pushed to the workbench 2, and the battery that has been coded is pushed out of the manipulator 4 of the workbench 2 at the same time.

[0039] The first conveyor belt 1 is provided with a battery guide channel 11 , and guide rollers 12 are provided on both sides of the battery guide channel 11 . The workbench 2 is provided with a battery guide channel 21, and both sides of the battery guide channel 21 are provided with guide rollers 22.

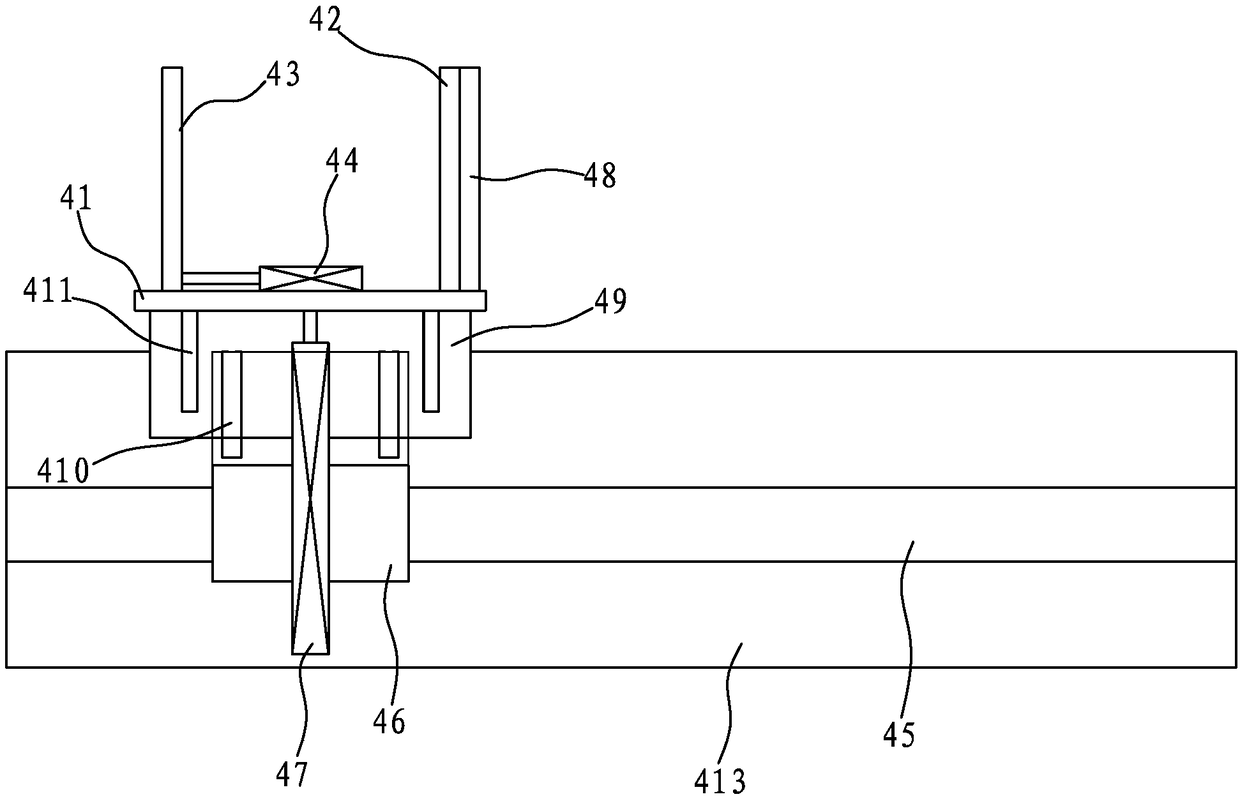

[0040] Such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com