A plastic spraying device

A technology of plastic spraying and plastic spraying tubes, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of uneven spraying of plastic powder, small application range, single spraying of one type of plastic powder, etc., to achieve convenient operation and wide practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

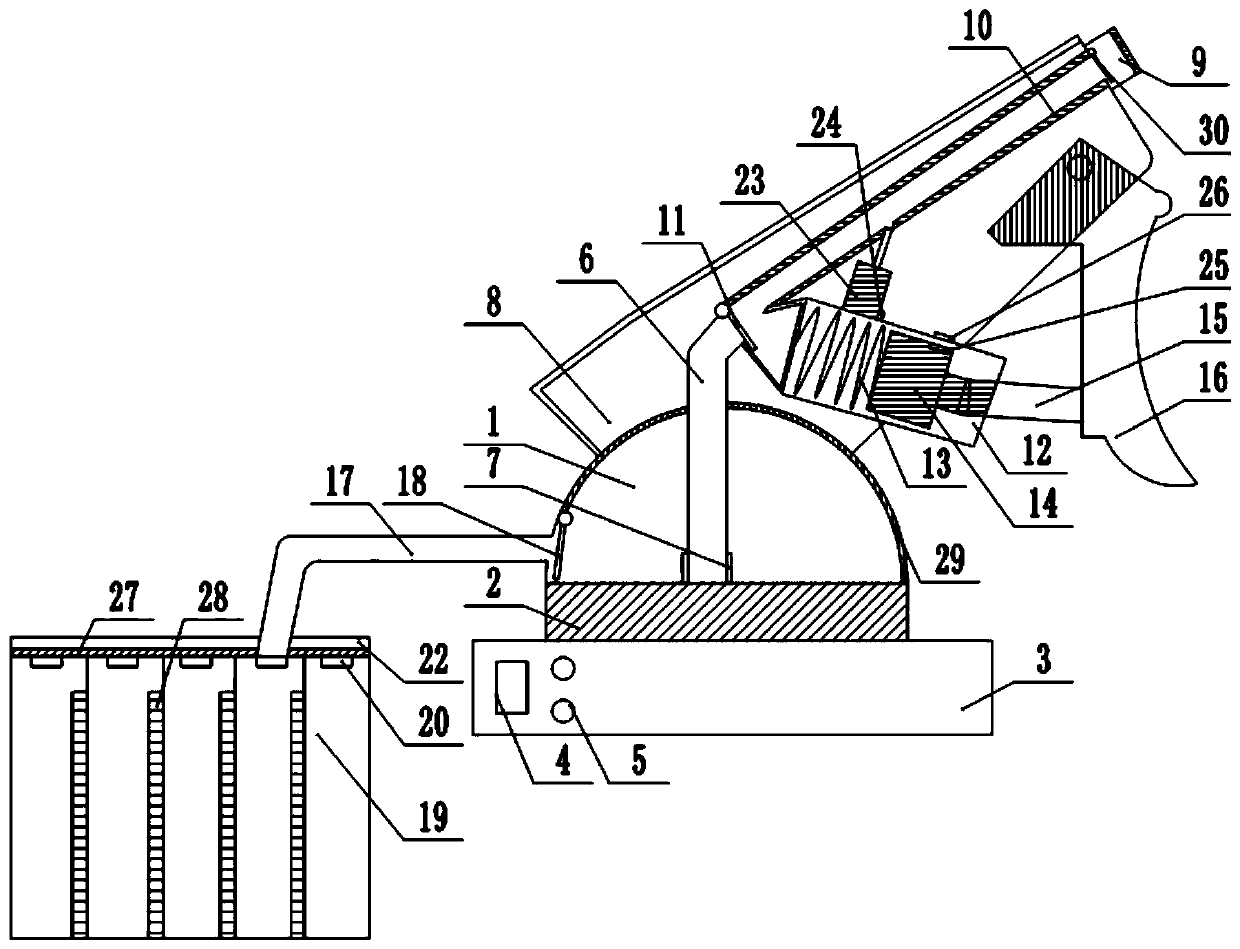

[0018] The reference signs in the drawings of the specification include: heating chamber 1, heating pad 2, heating base 3, heating switch 4, temperature control button 5, plastic feeding tube 6, plastic feeding port 7, spray gun 8, nozzle 9, plastic spraying tube 10. The first baffle 11, the first sliding tube 12, the spring 13, the slider 14, the pull rod 15, the handle 16, the plastic powder tube 17, the second baffle 18, the plastic powder box 19, the first opening 20, the second Chute 22, high-pressure pump 23, pressure switch 24, first magnet 25, second magnet 26, expansion plate 27, visible window 28, insulation layer 29, third baffle plate 30.

[0019] Such as figure 1 Shown: a plastic spraying device, including a heating mechanism, the heating mechanism includes a heating chamber 1, the upper part of the heating chamber 1 is provided with an insulating layer 29, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com