Multistage pore molecular sieve-supported heteropolyacid alkylation desulfurization catalyst and preparation method thereof

An alkylation desulfurization and molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. Transalkylation ability, improved accessibility and diffusivity, effect of high acid strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

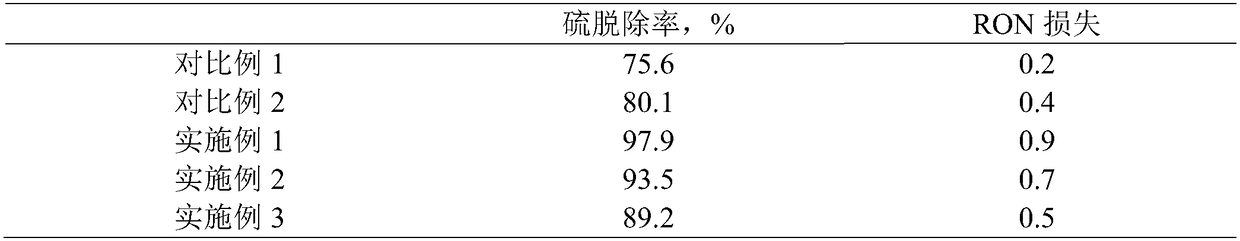

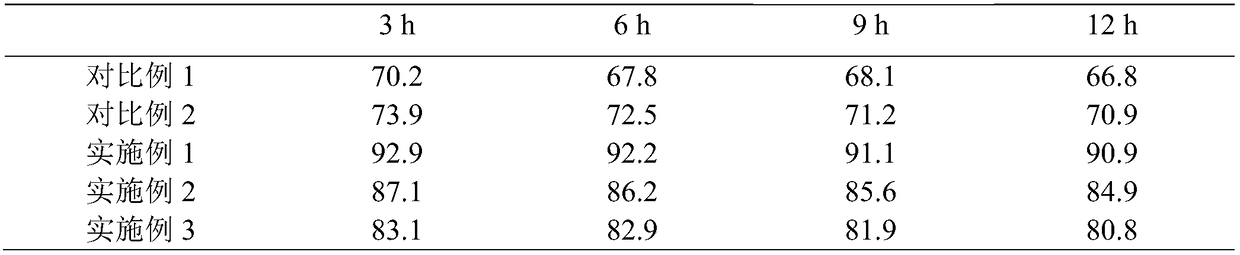

Examples

Embodiment 1

[0026] 100g SiO 2 / Al 2 o 3 NaY molecular sieve with a molar ratio of 10 was placed in 800 mL of hydrochloric acid and ammonium chloride mixed solution, wherein the concentration of hydrochloric acid and ammonium chloride solution was 1.2 mol / L, and the molar ratio of hydrochloric acid to ammonium chloride was 1.5. Stand at room temperature for 12 hours, filter, wash, dry, and roast to obtain acid-treated Y molecular sieve.

[0027] Mix the molecular sieve obtained above with 0.9mol / L tetramethylammonium hydroxide solution, the solid-to-liquid ratio of the molecular sieve to the lye is 1:5, treat it in a polytetrafluoroethylene-lined synthesis kettle at 80°C for 12h, and filter , washing, drying, and roasting to prepare a multi-level porous Y molecular sieve containing a mesoporous composite structure.

[0028] Put the above multi-stage molecular sieve into the mixed solution of sodium tungstate and ammonium dihydrogen phosphate, wherein the weight ratio of sodium tungstate...

Embodiment 2

[0030] Put 100g of NaY molecular sieve with SiO2 / Al2O3 molar ratio of 10 in 800mL hydrochloric acid and ammonium chloride mixed solution, wherein the concentration of hydrochloric acid and ammonium chloride solution is 1.2mol / L, and the molar ratio of hydrochloric acid to ammonium chloride is 1.5. Stand at room temperature for 12 hours, filter, wash, dry, and roast to obtain acid-treated Y molecular sieve.

[0031] Mix the molecular sieve obtained above with 0.9mol / L tetramethylammonium hydroxide solution, the solid-to-liquid ratio of the molecular sieve to the lye is 1:5, treat it in a polytetrafluoroethylene-lined synthesis kettle at 80°C for 12 hours, and filter , washing, drying, and roasting to prepare a multi-level porous Y molecular sieve containing a mesoporous composite structure.

[0032] Put the above-mentioned multi-stage porous molecular sieve into the mixed solution of ammonium molybdate and ammonium dihydrogen phosphate, wherein the weight ratio of ammonium moly...

Embodiment 3

[0034] 100g SiO 2 / Al 2 o 3 NaY molecular sieve with a molar ratio of 10 was placed in 800 mL of hydrochloric acid and ammonium chloride mixed solution, wherein the concentration of hydrochloric acid and ammonium chloride solution was 1.2 mol / L, and the molar ratio of hydrochloric acid to ammonium chloride was 1.5. Stand at room temperature for 12 hours, filter, wash, dry, and roast to obtain acid-treated Y molecular sieve.

[0035] Mix the molecular sieve obtained above with 0.9mol / L tetramethylammonium hydroxide solution, the solid-to-liquid ratio of the molecular sieve to the lye is 1:5, treat it in a polytetrafluoroethylene-lined synthesis kettle at 80°C for 12 hours, and filter , washing, drying, and roasting to prepare a multi-level porous Y molecular sieve containing a mesoporous composite structure.

[0036]Put the above-mentioned multi-stage molecular sieve into the mixed solution of sodium silicate and sodium tungstate, wherein the weight ratio of sodium silicate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com