Sulfonic functionalized mesoporous silicon dioxide microsphere loaded metal oxide catalyst and preparation method and application of catalyst

A technology of mesoporous silica and silica, which can be used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., and can solve the problems of loose bonding, uneven distribution, and low loading. , to achieve the effect of improving the degree of binding, the preparation method is simple and practical, and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

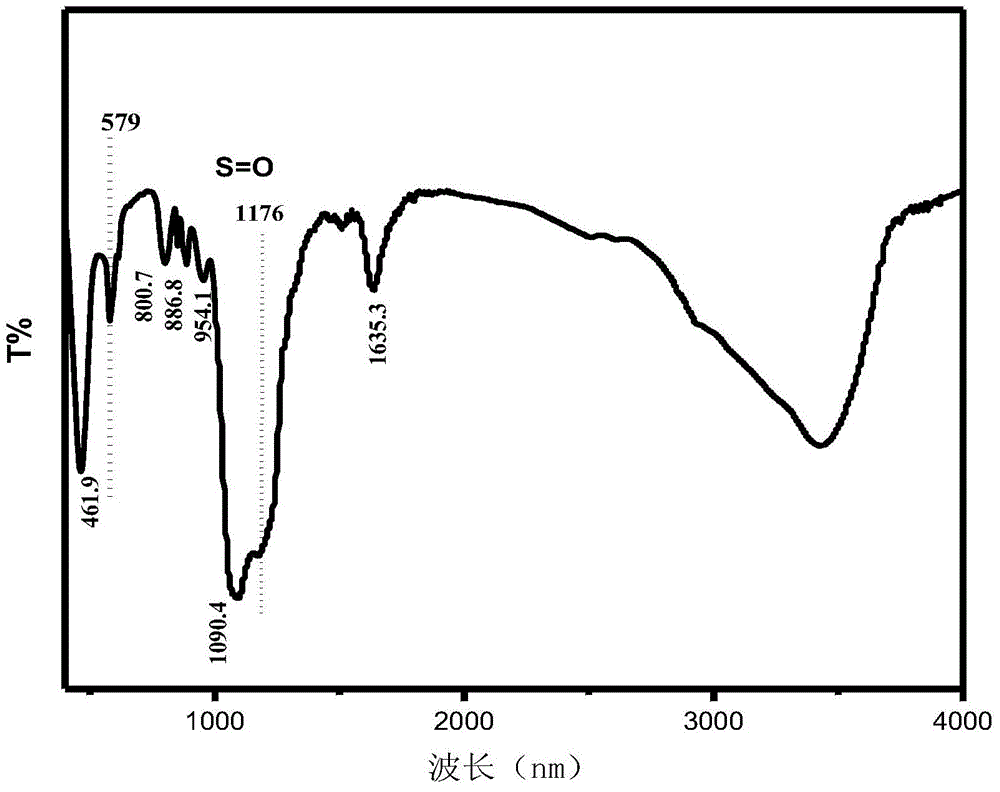

[0031] Mesoporous SiO 2 Sulfonic acid functionalization preparation of nanospheres:

[0032] Dissolve 0.7042g sodium N-lauroyl sarcosinate (Sar-Na) completely in 80ml dilute HCl solution (the concentration of HCl is 0.1mol / L); Propyltriethoxysilane mixture was added to the above solution, and then poured into the reaction kettle and left in an oven at 60°C for 15 hours. The obtained product was centrifuged, washed with deionized water and dried in vacuum to obtain white SiO 2 nanospheres.

[0033] A high-temperature calcination method is used to remove the surfactant in the pores. The dried 1.0g SiO2 The nano-microspheres were slightly ground, placed in a muffle furnace, and the temperature was programmed to rise to 600 ° C for 6 hours to obtain mesoporous SiO 2 nanospheres.

[0034] The prepared mesoporous SiO 2 Nanospheres (1.0g) were completely submerged in 15ml CH 2 Cl 2 solution, after ultrasonic dispersion, add 4ml of chlorosulfonic acid to the above mixture, ult...

Embodiment 2

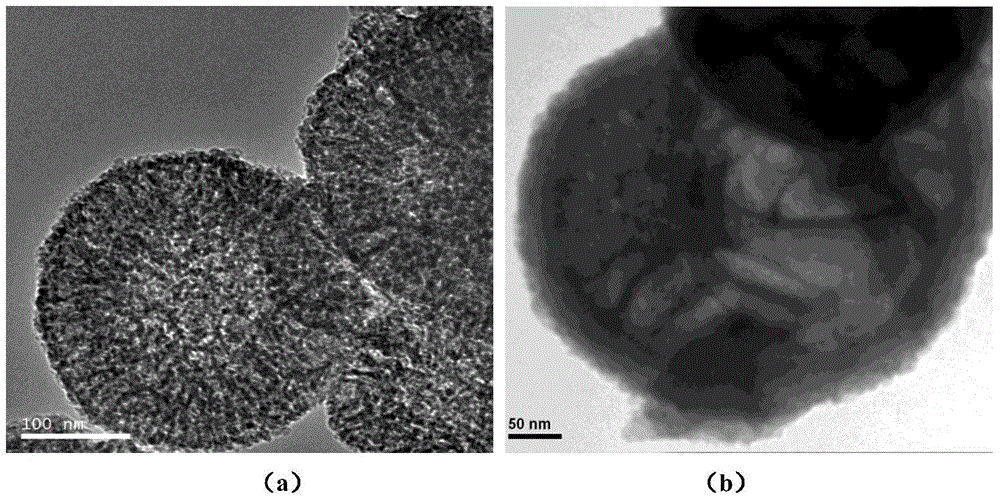

[0040] MnO 2 / mesoporous SO 3 H-SiO 2 Preparation of microspheres:

[0041] 1.0 g of mesoporous SO prepared in Example 1 3 H-SiO 2 Microsphere samples were dispersed in 100 mL of deionized water, 0.629 g of anhydrous manganese acetate solid (mass fraction of manganese ions accounted for 20% of the carrier) was added, stirred, transferred to a reaction kettle, and placed at 60°C for 8 hours. After cooling, centrifuge, wash the solid with deionized water, and dry it in a vacuum oven; take it out, grind it with a mortar, put it in a muffle furnace, and heat it up to 180 ° C for 6 hours to obtain a solid sample MnO 2 / mesoporous SO 3 H-SiO 2 Microspheres.

Embodiment 3

[0043] Cu 2-x mn x o 3 Loaded mesoporous SO 3 H-SiO 2 Preparation of nanospheres:

[0044] With SO prepared in embodiment 1 3 H-SiO 2 Mesoporous nanospheres were used as the carrier, and 1.0 g of the carrier was uniformly dispersed in 100 mL of deionized water, and 0.528 g of copper nitrate trihydrate and 0.189 g of anhydrous manganese acetate solid were added (the molar ratio of Cu to Mn was 2:1, and the total metal ions The mass fraction accounts for 20% of the carrier), and after stirring, it is transferred to a reaction kettle, and placed at a temperature of 60° C. for 8 hours. After cooling, centrifuge, wash the solid with deionized water, and dry it in a vacuum oven; take it out, grind it with a mortar, put it in a muffle furnace, and heat it up to 180°C for 6 hours to obtain a powdery solid sample Cu 2-x mn 0.5x o 2 / SO 3 H-SiO 2 Microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com