Composite nuclear track membrane and preparation method thereof

A technology of nuclear pore membrane and composite core, which is applied in the field of composite nuclear pore membrane and its preparation, can solve the problems of poor hydrophilicity, thin film and low mechanical strength, achieve good hydrophilicity, solve the problem of pre-filtration, The effect of strong dirt holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

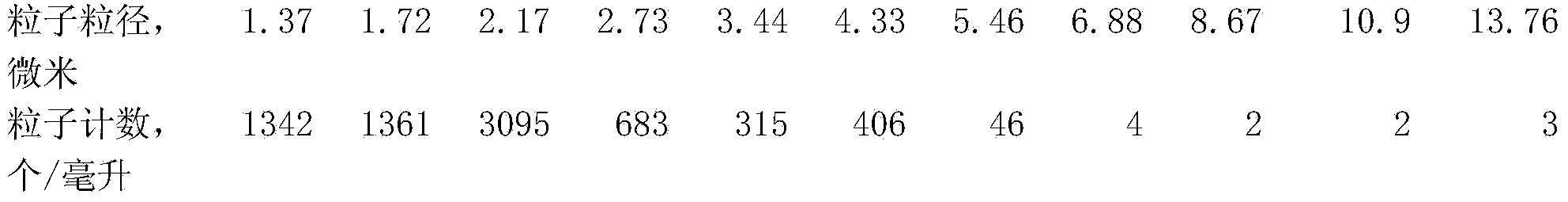

[0022] A preparation method of a composite nuclear pore membrane, comprising the following steps: dissolving diester acid cellulose in a mixed solvent under stirring at room temperature to make a solution with a mass percentage of 8%, adding glycerin to make a casting solution , the mass ratio of glycerol to cellulose diester is 3.6:1, the casting solution is left to stand for 1 hour, and the casting solution is coated on the polyester nuclear pore membrane with a thickness of 400 μm on a constant temperature and humidity coating machine, The length of the coating machine is 60 meters. Under the conditions of 60°C and relative humidity of 99%, the coating speed is 1.5 m / min and it is treated for 40 minutes. It is placed in deionized water in a constant temperature water bath, soaked at room temperature for 1 hour, and dried to obtain A composite nuclear pore membrane with a thickness of 160 μm, the mixed solvent is acetone and dimethylformamide with a volume ratio of 0.62:1; th...

Embodiment 2

[0027] A method for preparing a composite nuclear pore membrane, comprising the steps of: dissolving diester acid cellulose in a mixed solvent under stirring at room temperature to make a solution with a mass percentage of 6%, adding glycerin to make a casting solution , the mass ratio of glycerol to cellulose diester is 3:1, the casting solution is left to stand for 30 minutes, and the casting solution is coated on the polyester nuclear pore membrane with a thickness of 500 μm on a constant temperature and humidity coating machine, The length of the coating machine is 60 meters. Under the conditions of 50 ° C and a relative humidity of 90%, the coating speed is 1.0 m / min and the treatment is 60 minutes. It is placed in deionized water in a constant temperature water bath, soaked at room temperature for 2 hours, and dried to obtain A composite nuclear pore membrane with a thickness of 160 μm, the mixed solvent is acetone and dimethylformamide with a volume ratio of 0.7:1; the p...

Embodiment 3

[0030] A preparation method of a composite nuclear pore membrane, comprising the following steps: dissolving diester acid cellulose in a mixed solvent under stirring at room temperature to make a solution with a mass percentage of 7%, adding glycerin to make a casting solution , the mass ratio of glycerol to cellulose diester is 3.3:1, the casting solution is left to stand for 2 hours, and the casting solution is coated on the polycarbonate nuclear pore membrane with a thickness of 200 μm on a constant temperature and humidity coating machine , the length of the coating machine is 60 meters, under the conditions of 70 ℃ and relative humidity of 95%, the coating speed is 2.0 m / min, and the treatment is 30 minutes. Place it in the deionized water of the constant temperature water bath machine, soak it at room temperature for 2 hours, and dry it. Obtaining a composite nuclear pore membrane with a thickness of 85 μm, the mixed solvent is acetone and dimethylformamide with a volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com