Preparation method of phosphotungstic acid doped titanium dioxide photocatalyst

A titanium dioxide and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of cumbersome steps and high energy consumption, achieve strong photocatalytic activity, improve separation efficiency, The effect of improving the photon quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

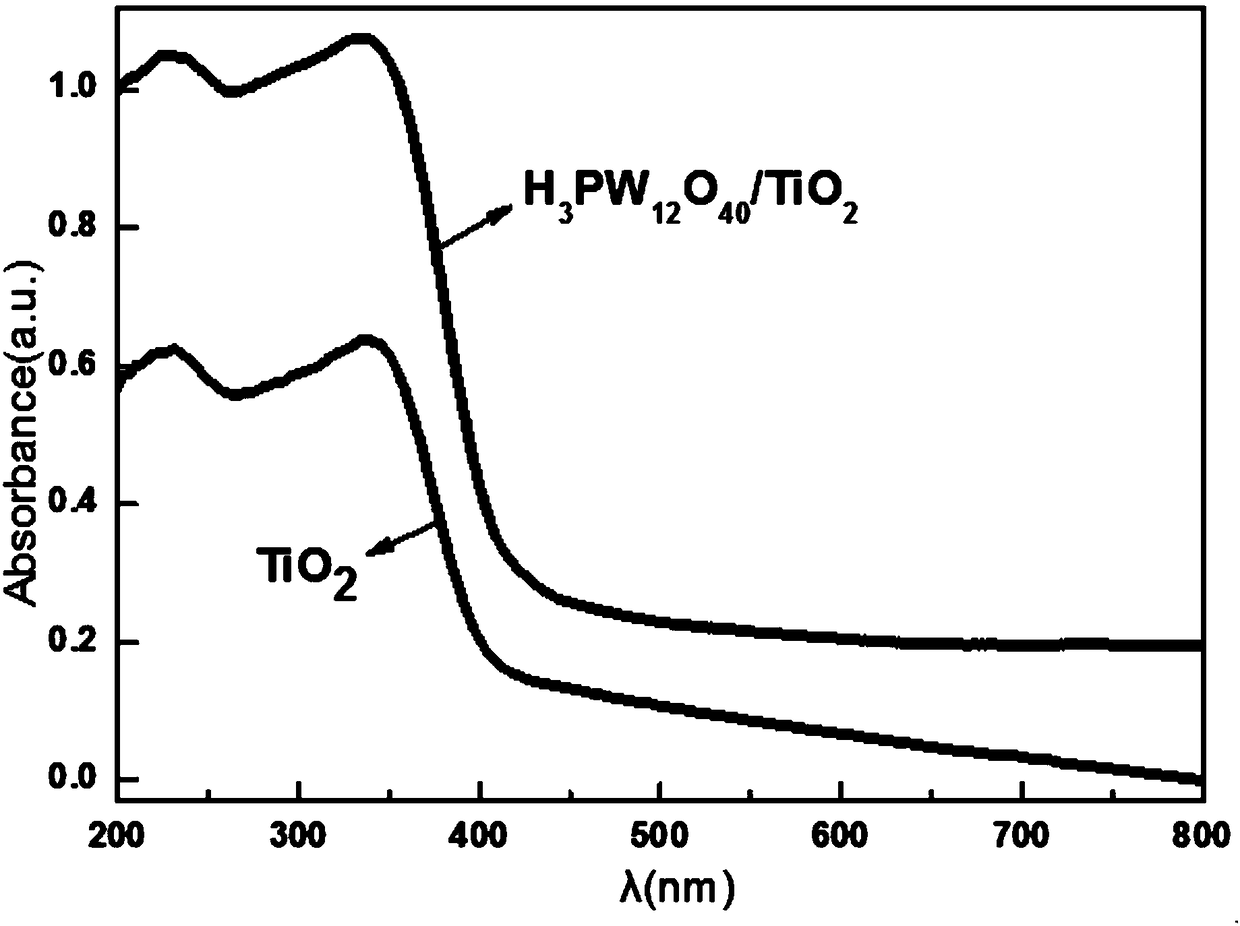

Image

Examples

Embodiment 1

[0030] Step 1. Add a certain amount of butyl titanate dropwise into absolute ethanol to make it uniformly dispersed, and add a small amount of glacial acetic acid and triethanolamine dropwise, and stir. The stirring speed is 800r / min, and the stirring time is 20min. The obtained liquid is recorded as liquid A, wherein the volume ratio of absolute ethanol to butyl titanate is 2:1, glacial acetic acid is 10% of the volume of butyl titanate, and triethanolamine is 5% of the volume of butyl titanate. %;

[0031] Step 2, adding a certain amount of dehydrated alcohol into the mixed solution of a small amount of distilled water and glacial acetic acid, stirring, the stirring speed is 800r / min, the stirring time is 10min, leave standstill, the liquid obtained is recorded as B liquid, wherein, no The volume of hydroalcohol is 50% of the volume of dehydrated alcohol in step 1, and the volume of distilled water is 15% of the volume of dehydrated alcohol in step 2, and glacial acetic acid...

Embodiment 2

[0036] Step 1. Add a certain amount of butyl titanate dropwise into absolute ethanol to make it uniformly dispersed, and add a small amount of glacial acetic acid and triethanolamine dropwise, and stir. The stirring speed is 800r / min, and the stirring time is 40min. The obtained liquid is recorded as liquid A, wherein the volume ratio of absolute ethanol to butyl titanate is 2:1, glacial acetic acid is 20% of the volume of butyl titanate, and triethanolamine is 10% of the volume of butyl titanate. %;

[0037] Step 2, adding a certain amount of dehydrated alcohol into the mixed solution of a small amount of distilled water and glacial acetic acid, stirring, the stirring speed is 1200r / min, the stirring time is 30min, leave standstill, the liquid obtained is recorded as B liquid, wherein, no The volume of hydroalcohol is 50% of the volume of dehydrated alcohol in step 1, and the volume of distilled water is 15% of the volume of dehydrated alcohol in step 2, and glacial acetic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com