Composite semi-permeable membrane containing Cu2-xS for light evaporable water as well as preparation method and application thereof

A composite semi-permeable membrane, cu2-xs technology, applied in semi-permeable membrane separation, general water supply saving, membrane technology and other directions, can solve the problem of high price of precious metal membrane, and achieve the effect of good light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation of semipermeable membrane precursor solution:

[0056] Slowly add concentrated sulfuric acid to concentrated nitric acid dropwise, the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 2:1, mix well to obtain a mixed acid solution;

[0057] Immerse the absorbent cotton in the mixed acid solution, take it out, rinse it with deionized water, and dry it to obtain cellulose nitrate;

[0058] Take cellulose nitrate, dissolve it in a mixed solution of ethanol and ether with a volume ratio of 1:1, and mix well to obtain a transparent semipermeable membrane precursor solution.

[0059] Preferably, the solvent for preparing the semipermeable membrane precursor solution includes: ether solvent and / or alcohol solvent.

[0060] More preferably, the solvent for preparing the semipermeable membrane precursor solution is a mixture of ethanol and ether at a volume ratio of 1:1.

[0061] A Cu-containing 2-x The purposes of the composite semipermeab...

Embodiment 1

[0063] 1. Preparation of 3D-CuS nanoflowers

[0064] 0.20g CuCl 2 2H 2 O and 0.02g of thiourea were dissolved in a beaker with 10mL of deionized water, and ultrasonicated for 5min to make them evenly dispersed in deionized water. Afterwards, the two solutions were mixed and ultrasonicated for 5 min, so that the two solutions were evenly mixed. Subsequently, the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and the reactor was placed in an oven at 120° C. for 18 h. After taking out the autoclave, it was allowed to cool to room temperature in air. Then, the prepared black suspension was collected, washed 6 times with deionized water and ethanol, respectively, and then the black precipitate was collected by centrifugation. Finally, the collected black precipitate was dried in an oven at 60° C. for 5 h to obtain a black powder of 3D-CuS nanoflowers.

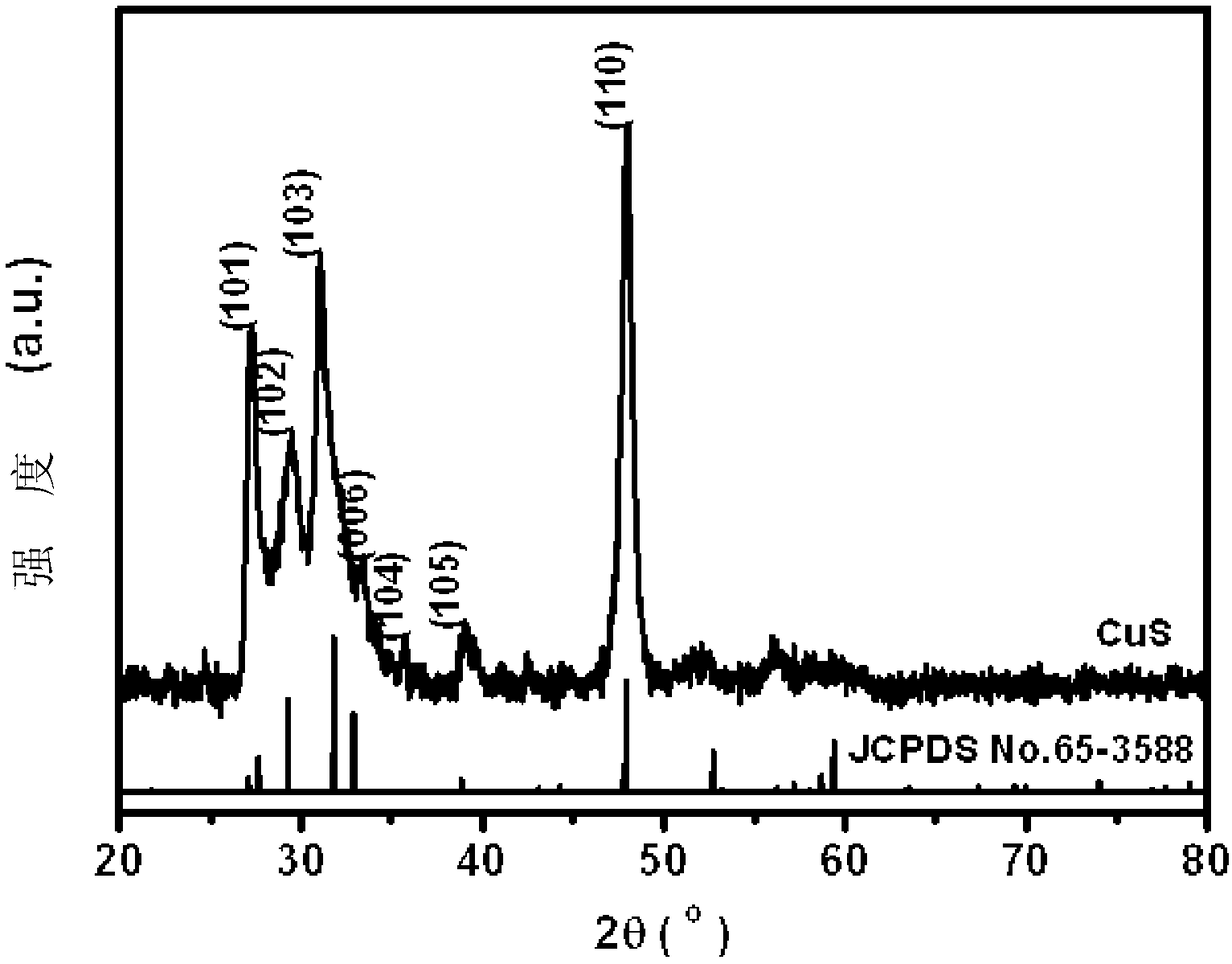

[0065] Such as figure 1 As shown, it is the XRD (X-ray diffraction, X-ray diffra...

Embodiment 2

[0076] 72 mg of CuS powder was added to a beaker containing 1 mL of ethanol solution, and ultrasonicated for 5 min to obtain a uniformly mixed CuS ethanol solution.

[0077] Take out 2mL of the semipermeable membrane precursor solution with a dropper and slowly add it to the CuS ethanol solution above. After the dropwise addition, stir magnetically for 15 minutes to obtain a uniform mixed solution.

[0078] Take out 1.5mL of the mixed solution and add it to the bottom of a 500mL glass beaker with an inner diameter of 74mm, and let it dry naturally in the air to form a film. Then, it was cut into a circular film with a diameter of 34 mm, thus successfully preparing a 3D-CuS nanoflower composite semipermeable membrane with a content of about 8 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com