Temperature-drift-free on-chip integrated laser and preparation method thereof

An integrated laser and temperature drift technology, which is applied in the structure of optical resonator cavity, structure of optical waveguide semiconductor, etc., can solve the problems of low power consumption of on-chip integrated laser, change of output wavelength with temperature, low preparation cost, etc., and achieves practicability. Strong, reduce power consumption, improve the effect of coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

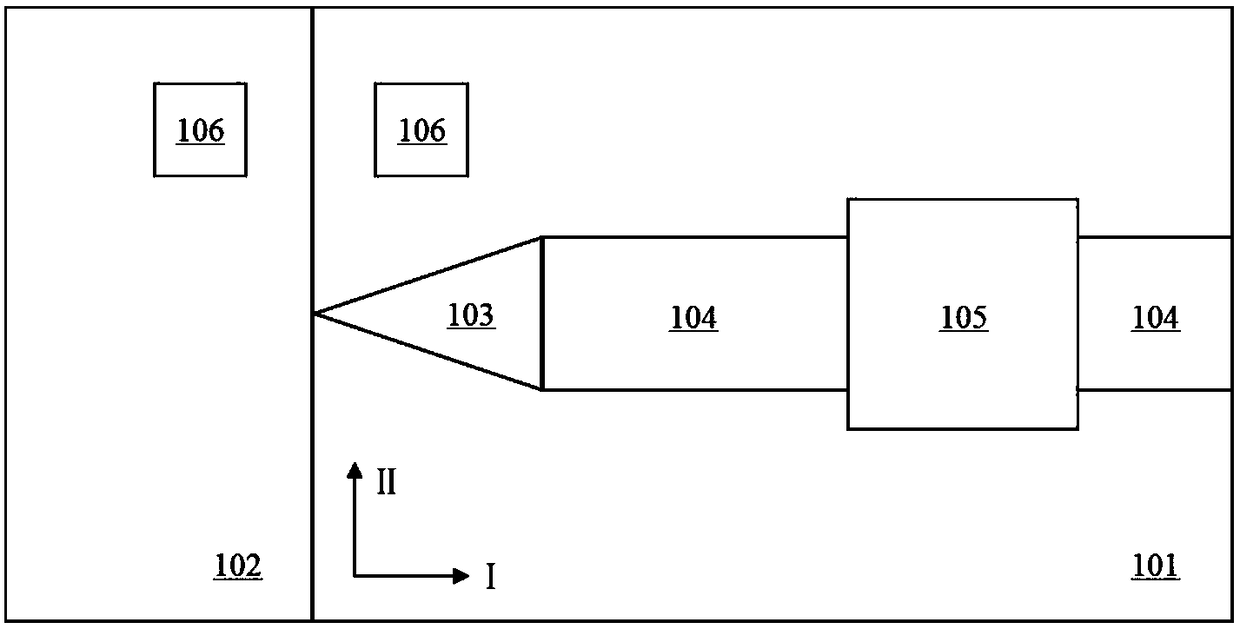

[0051] see Figure 1 to Figure 3 As shown, Embodiment 1 provides an on-chip integrated laser without temperature drift, including a low-refractive index substrate 101, a gain medium 102, a mode spot converter 103, a hybrid integrated optical waveguide 104 without temperature drift, and an optical waveguide without temperature drift. Resonant cavity 105 and a pair of alignment marks 106 . Wherein, the gain medium 102 is a quantum well structure based on the InGaAsP / InP material system, and realizes stimulated emission by electric pumping. The mode speckle converter 103 adopts an inverted tapered waveguide structure, and couples the light wave output by the gain medium 102 into the hybrid integrated optical waveguide 104 without temperature drift, and couples it into the optical resonant cavity 105 without temperature drift to realize the frequency selection function. A total reflection mirror is arranged on one side of the gain medium 102, and the total reflection mirror toget...

Embodiment 2

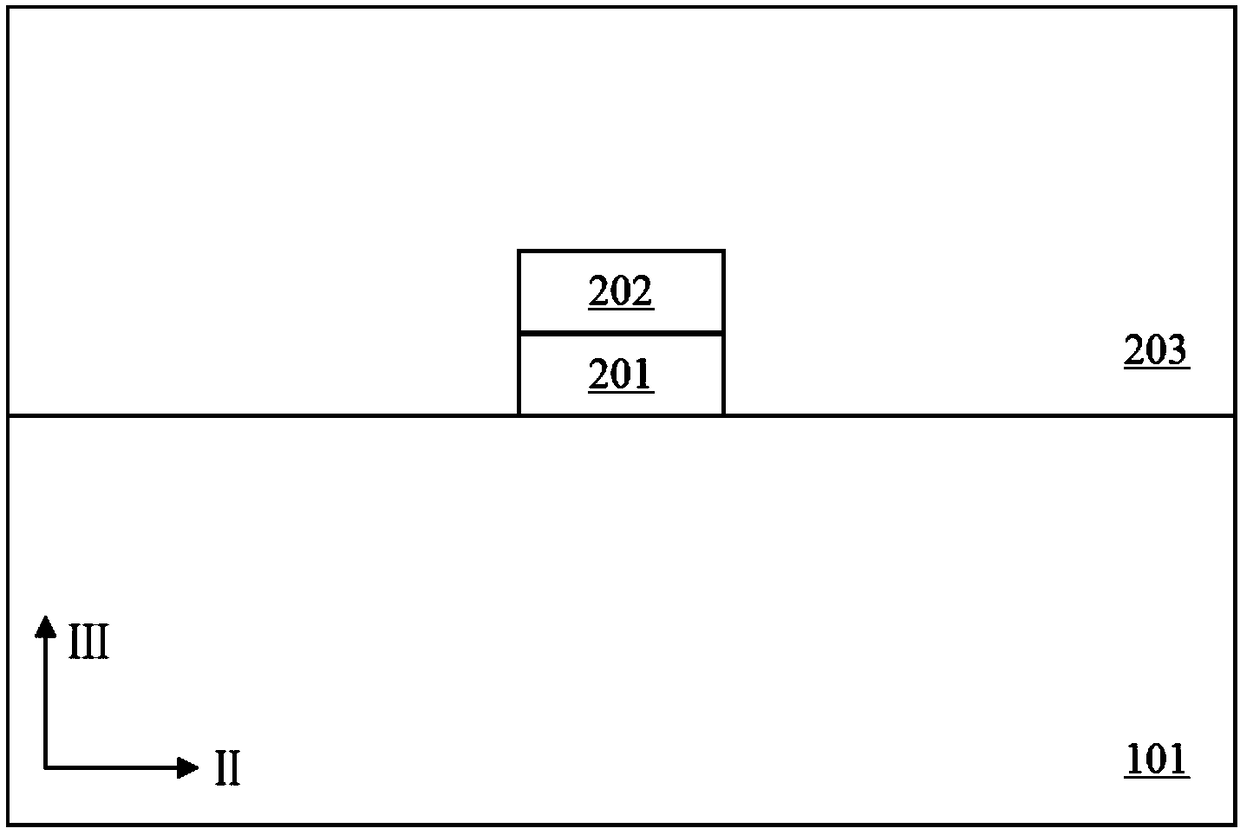

[0054] see Figure 4 with Figure 5 As shown, Embodiment 2 provides an on-chip integrated laser without temperature drift, and its basic structure is the same as that of Embodiment 1, except that: see Figure 4 As shown, the hybrid integrated optical waveguide 104 without temperature drift adopts a slit waveguide structure, including a high-refractive-index material layer 201 formed on a low-refractive-index substrate 101; The optical coefficient material layer 202 ; the low refractive index covering layer 203 formed on the negative thermo-optic coefficient material layer 202 . The materials of the low-refractive-index substrate 101 and the low-refractive-index cover layer 203 are both silicon dioxide, with a refractive index of 1.444 and a thermo-optic coefficient of 1.0*10 -5 K -1 ; The material of the high refractive index material layer 201 is silicon, the refractive index is 3.45, and the thermo-optic coefficient is 1.84*10 - 4 K -1 ; The material of the negative th...

Embodiment 3

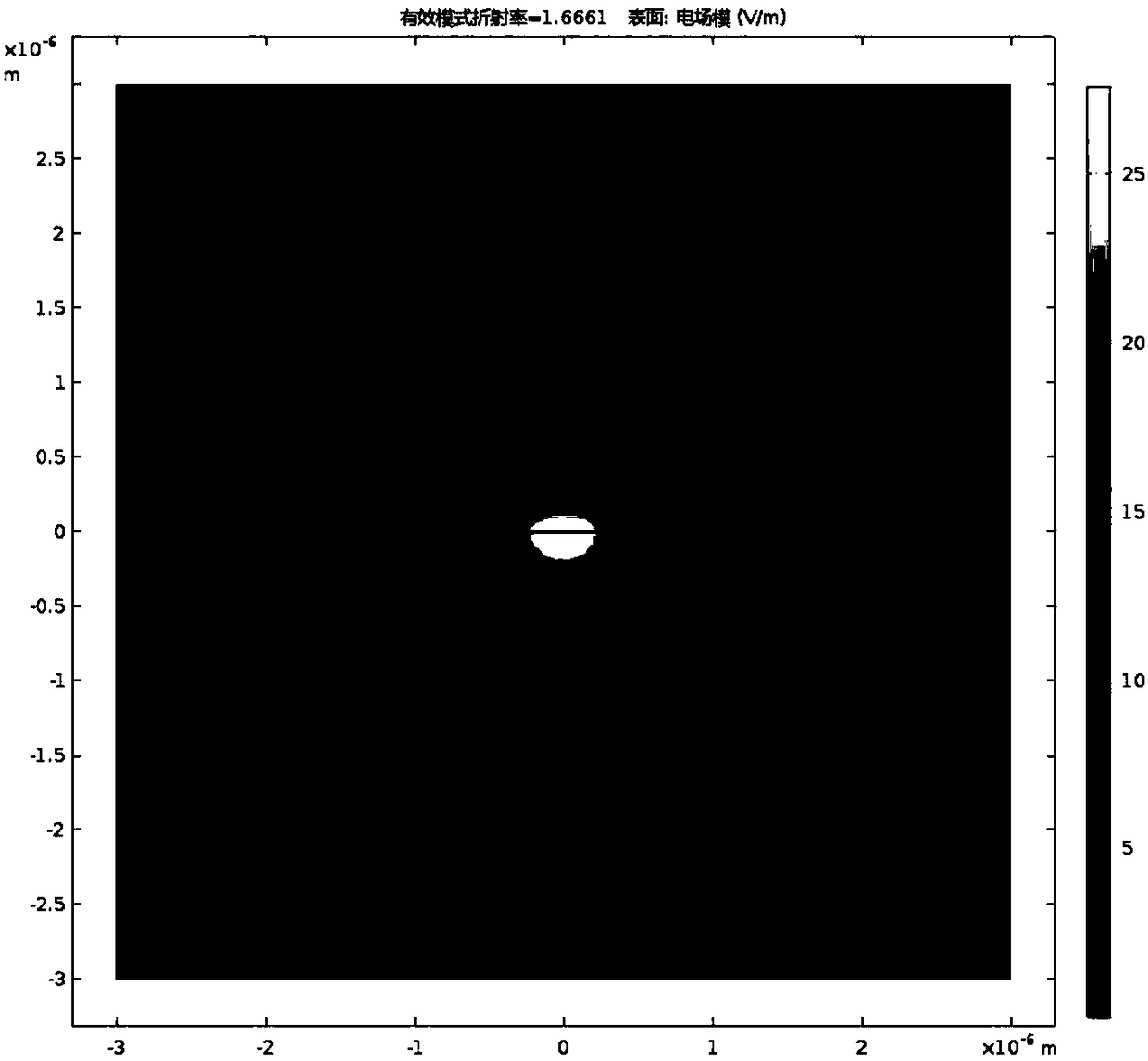

[0056] see Image 6 As shown, Embodiment 3 provides an on-chip integrated laser without temperature drift, and its basic structure is the same as that of Embodiment 1, except that: see Image 6 As shown, the hybrid integrated optical waveguide 104 without temperature drift adopts a sub-wavelength grating waveguide structure, including a periodically arranged high refractive index material layer 201 formed on a low refractive index substrate 101; formed on the high refractive index material layer 201 The negative thermo-optic coefficient material layer 202 arranged periodically in the middle; the low refractive index covering layer 203 formed on the negative thermo-optic coefficient material layer 202 . The materials of the low-refractive-index substrate 101 and the low-refractive-index cover layer 203 are both silicon dioxide, with a refractive index of 1.444 and a thermo-optic coefficient of 1.0*10 -5 K -1 ; The material of the high refractive index material layer 201 is si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thermo-optic coefficient | aaaaa | aaaaa |

| Thermo-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com