Axial pressure detection system and method for ball screw raceway surface grinding device

A technology of axial pressure and ball screw, which is applied in the direction of grinding device, grinding machine tool, metal processing equipment, etc., can solve the problems of limiting the service performance of the ball screw pair, limiting the grinding precision of the screw raceway surface, etc., and achieving measurement Sensitive and fast process, good oil resistance and wear resistance, effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

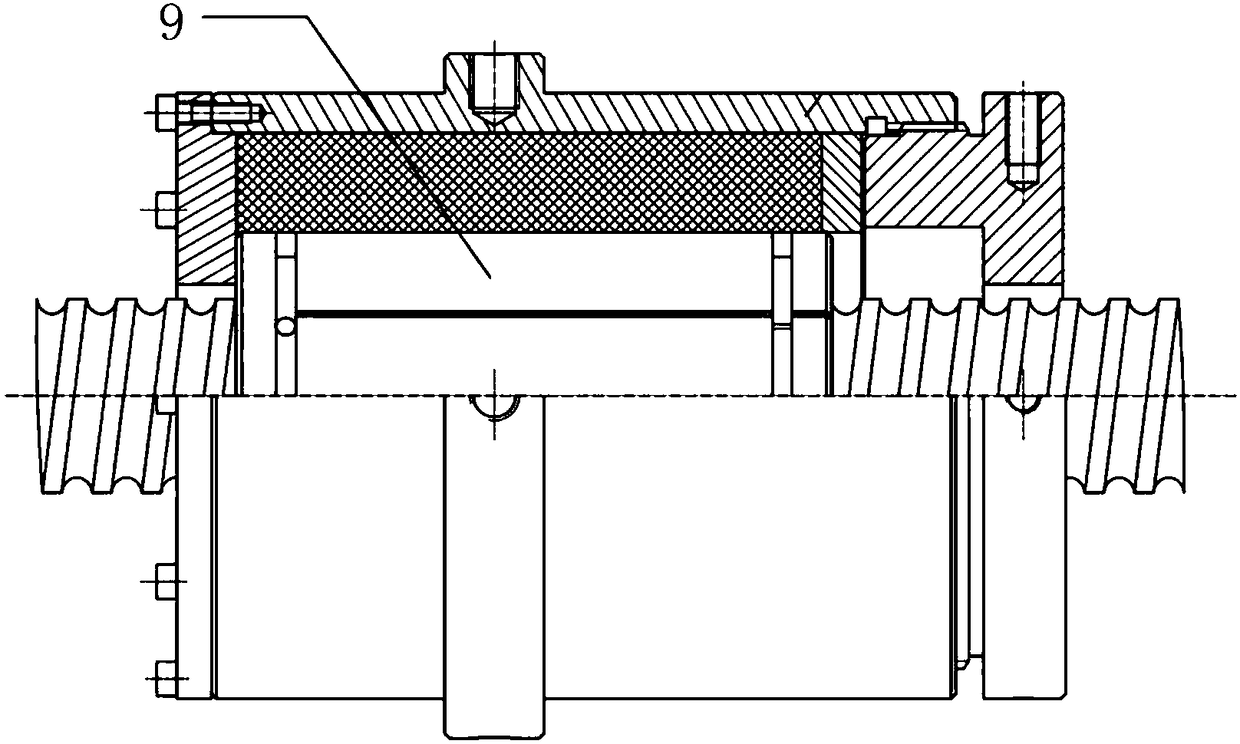

[0051] The system of the present invention can apply axial pressure to the elastic deformation ring 7 by using the grinding force module, so that the inner wall produces a small deformation; this deformation passes through the full-bridge measurement circuit under the cooperation of a set of full-bridge strain gauges 6 and strain gauges 2 Converted into a voltage signal and output to the computer processing system 1, the detection of the axial pressure of the screw raceway surface grinding system can be realized.

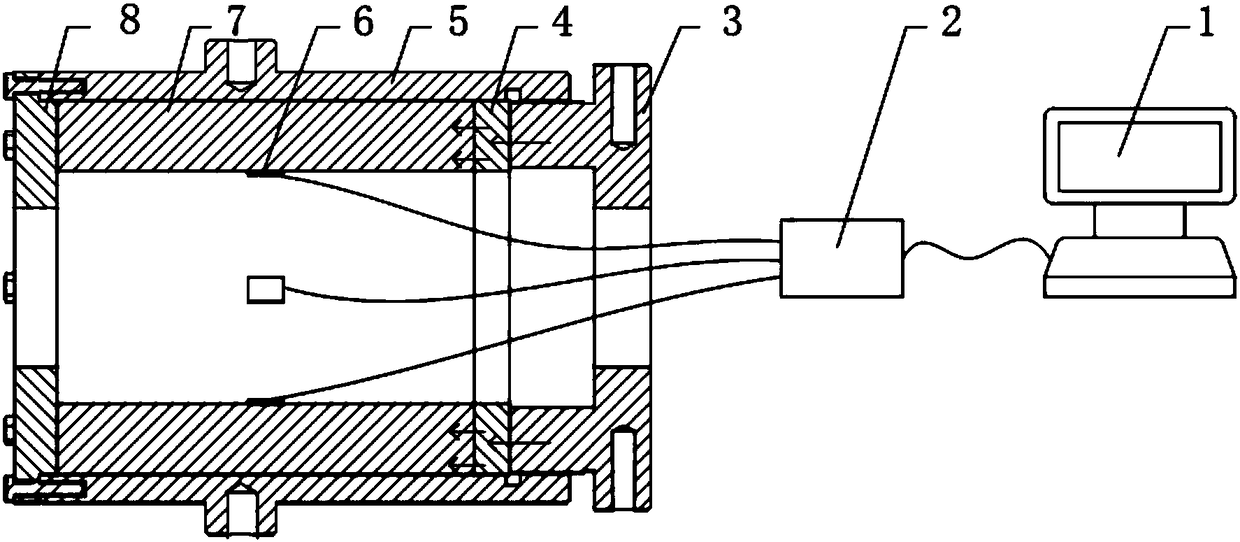

[0052] figure 1 Shown is the working principle of the axial pressure detection system of the ball screw raceway surface grinding device. It can be seen from the figure that the grinding force module is mainly composed of a threaded end cap 3 , a gasket 4 , an outer ring sleeve 5 , and an end cap baffle 8 . The working principle of the grinding and boosting module is as follows: the end cover baffle plate 8 is fixedly connected to one end of the outer ring sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com