Intelligent silicon-based wafer ultra-precision grinding and polishing machine based on self-learning

A self-learning, ultra-precise technology, applied in grinding/polishing equipment, grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, etc. Improve the grinding efficiency, improve the grinding effect, and achieve the effect of uniform grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

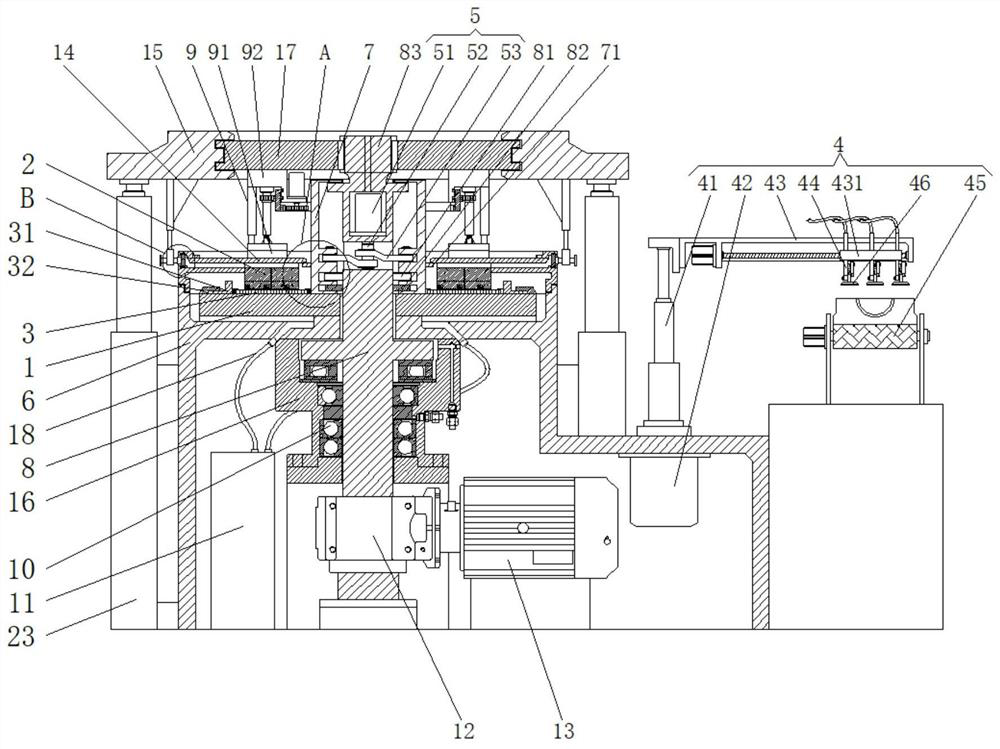

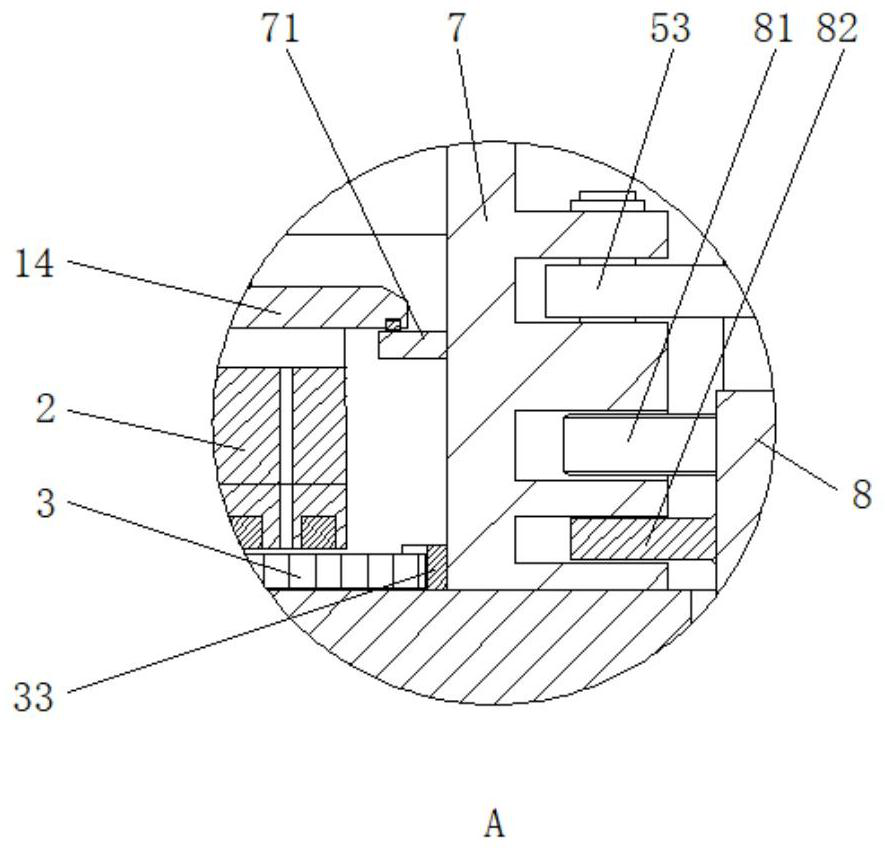

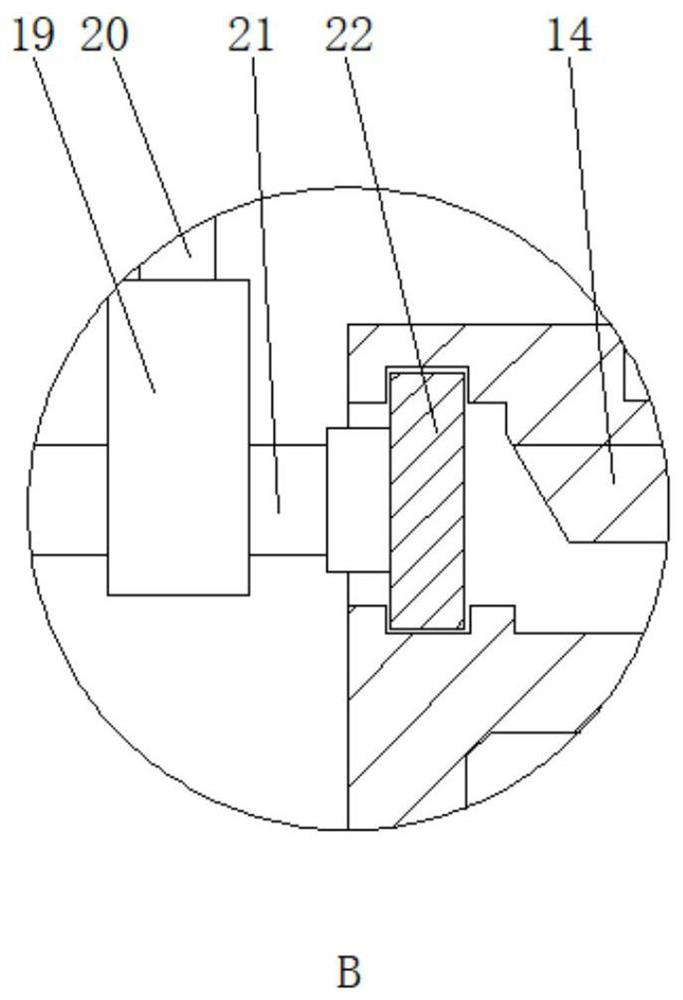

[0057] like Figure 1-Figure 15 As shown, the intelligent silicon-based wafer ultra-precision grinding and polishing machine based on self-learning includes a stage 6, a lower grinding stage 1 is arranged on the top of the stage 6, and a main shaft 8 is passed through the middle of the lower grinding stage 1 and the stage 6 , and the upper grinding table 2 is arranged above the lower grinding table 1, and the outer casing of the main shaft 8 is provided with an eccentric transmission cylinder 7, and the eccentric transmission cylinder 7 is connected with the main shaft 8 through the eccentric movement mechanism 5, and the main shaft 8 is connected with the planetary gear through the eccentric transmission cylinder 7. Moving workpiece plate 3;

[0058] A pressure plate 14 is connected to the top of the upper grinding table 2. The outer wall and inner wall of the pressure plate 14 are movably matched with the top outer wall of the table 6 and the outer wall of the eccentric tran...

Embodiment 2

[0066] like Figure 1-Figure 15 As shown, the intelligent silicon-based wafer ultra-precision grinding and polishing machine based on self-learning includes a stage 6, a lower grinding stage 1 is arranged on the top of the stage 6, and a main shaft 8 is passed through the middle of the lower grinding stage 1 and the stage 6 , and the upper grinding table 2 is arranged above the lower grinding table 1, and the outer casing of the main shaft 8 is provided with an eccentric transmission cylinder 7, and the eccentric transmission cylinder 7 is connected with the main shaft 8 through the eccentric movement mechanism 5, and the main shaft 8 is connected with the planetary gear through the eccentric transmission cylinder 7. Moving workpiece plate 3;

[0067] A pressure plate 14 is connected to the top of the upper grinding table 2. The outer wall and inner wall of the pressure plate 14 are movably matched with the top outer wall of the table 6 and the outer wall of the eccentric tran...

Embodiment 3

[0077] like Figure 1-Figure 15 As shown, the intelligent silicon-based wafer ultra-precision grinding and polishing machine based on self-learning includes a stage 6, a lower grinding stage 1 is arranged on the top of the stage 6, and a main shaft 8 is passed through the middle of the lower grinding stage 1 and the stage 6 , and the upper grinding table 2 is arranged above the lower grinding table 1, and the outer casing of the main shaft 8 is provided with an eccentric transmission cylinder 7, and the eccentric transmission cylinder 7 is connected with the main shaft 8 through the eccentric movement mechanism 5, and the main shaft 8 is connected with the planetary gear through the eccentric transmission cylinder 7. moving workpiece plate 3;

[0078] A pressure plate 14 is connected to the top of the upper grinding table 2. The outer wall and inner wall of the pressure plate 14 are movably matched with the top outer wall of the table 6 and the outer wall of the eccentric tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com