Grinding and feeding device for ice cream machine

A technology of ice cream machine and feeding device, which is applied in frozen sweets, food science, application, etc. It can solve the problems of waste, large amount of ice cream residue, and insufficient grinding of ice cream, so as to achieve the effect of delicate taste and quality of bite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

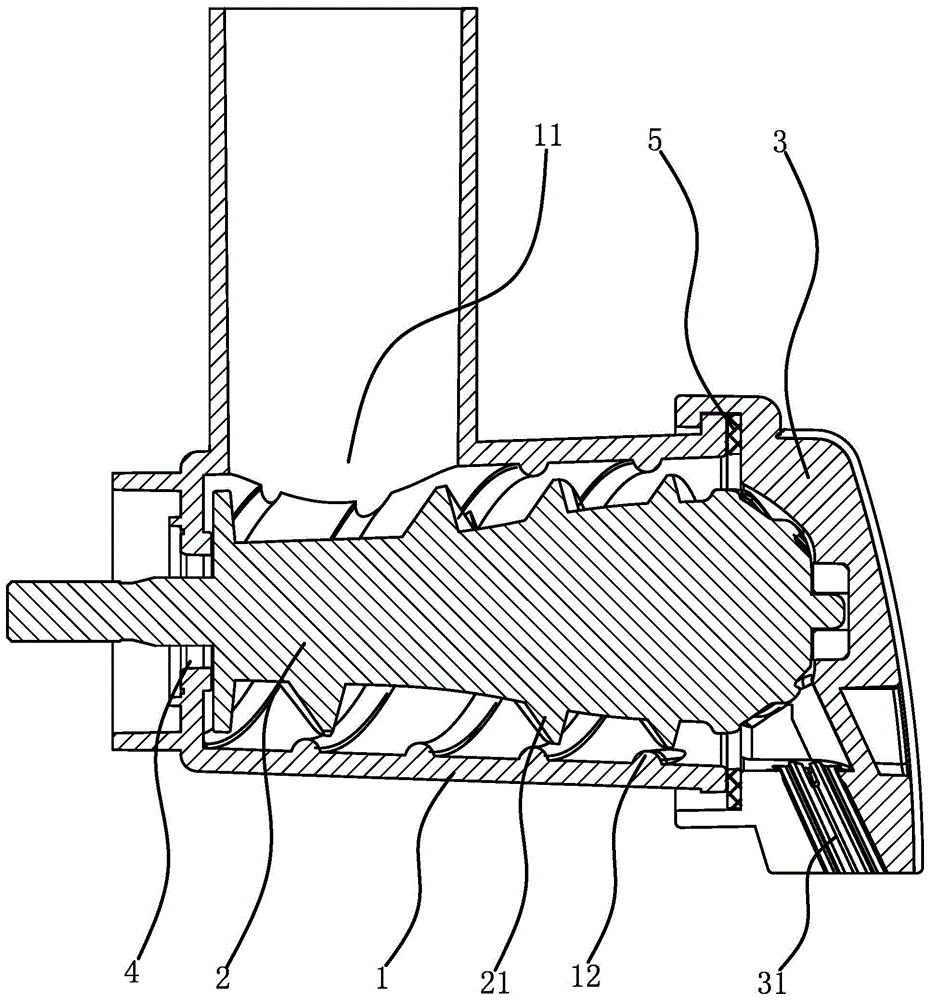

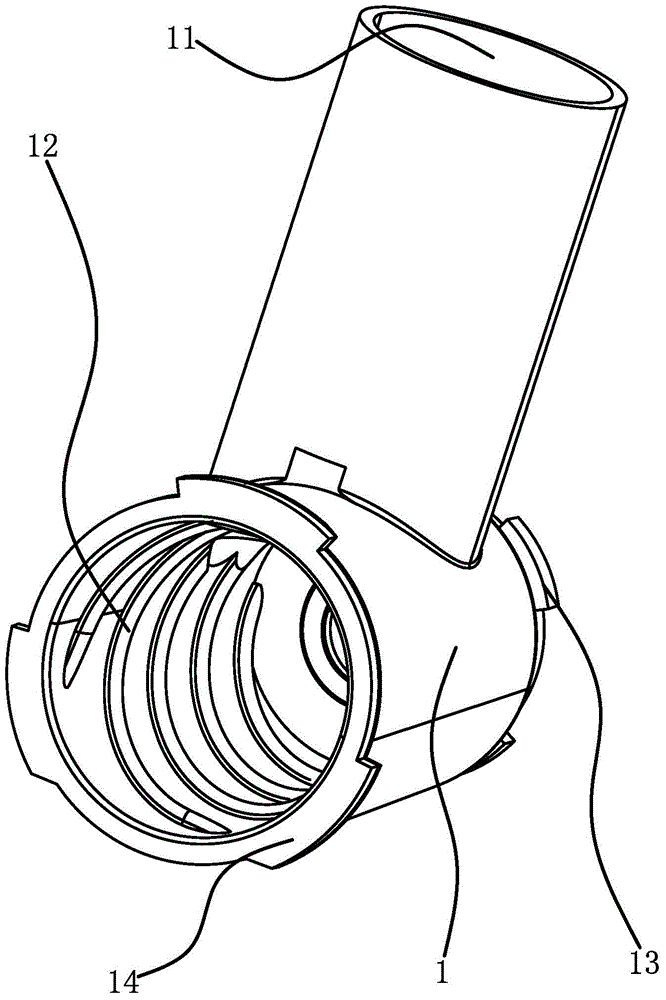

[0030] Such as figure 1 As shown, a grinding and feeding device of an ice cream machine, the ice cream machine includes a housing and a drive mechanism composed of a drive motor and a gearbox, the grinding and feeding device includes a barrel 1 and a screw 2, and the side wall of the barrel 1 is provided with radially There is a feeding port 11, and an end cap 3 is fixedly connected to one end of the barrel 1, and the end cap 3 has a discharging port 31. The screw 2 is installed in the barrel 1, one end of the screw 2 is rotatably connected to the inner wall of the end cover 3, the other end passes through the barrel 1 and is connected with the output shaft of the gearbox, the outer wall of the screw 2 is connected to the barrel 1 There is a gap between the inner side walls, and the ice cream raw materials pass through the gap, and the gap gradually decreases from the inlet to the outlet. The outer wall of the screw 2 has an outer screw edge 21 along the length direction. The...

Embodiment 2

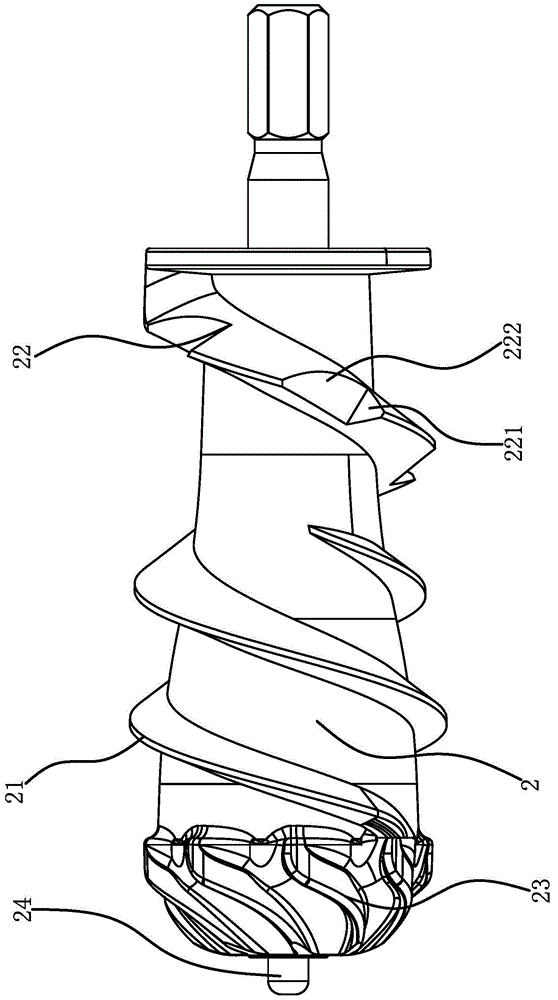

[0037] The structure of the grinding and feeding device of this ice cream machine is basically the same as that of Embodiment 1, the difference is that there are three outer screw ribs 21 of the screw rod 2, and one of the outer screw ribs 21 is spirally extended from one end of the screw rod 2 to the other end. The notch 22 is located on the outer screw ribs 21, and its pitch is roughly the same and larger, so that the block fruit can fall between the outer screw ribs 21. The other two outer screw ribs 21 are spirally extended from the middle of the screw rod 2 to have grinding teeth. 23, the ends of the three outer screw ribs 21 are evenly distributed in the circumferential direction. There are three inner screw ribs 12, and the three inner screw ribs 12 all extend from one end of the barrel 1 to the other end, and the distance between every two adjacent inner screw ribs 12 is equal, and the inner screw ribs 12 are facing toward the discharge port 31. One end is evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com