Chain scraper conveyor system for conveying waste purple impure copper

A technology of chain-slab conveyors and red miscellaneous copper, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve the problem of damaged chain-slab conveyors, easily damaged chain-slab conveyors, and copper wire materials that are easy to interact with each other Winding and other problems to achieve the effect of preventing material embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

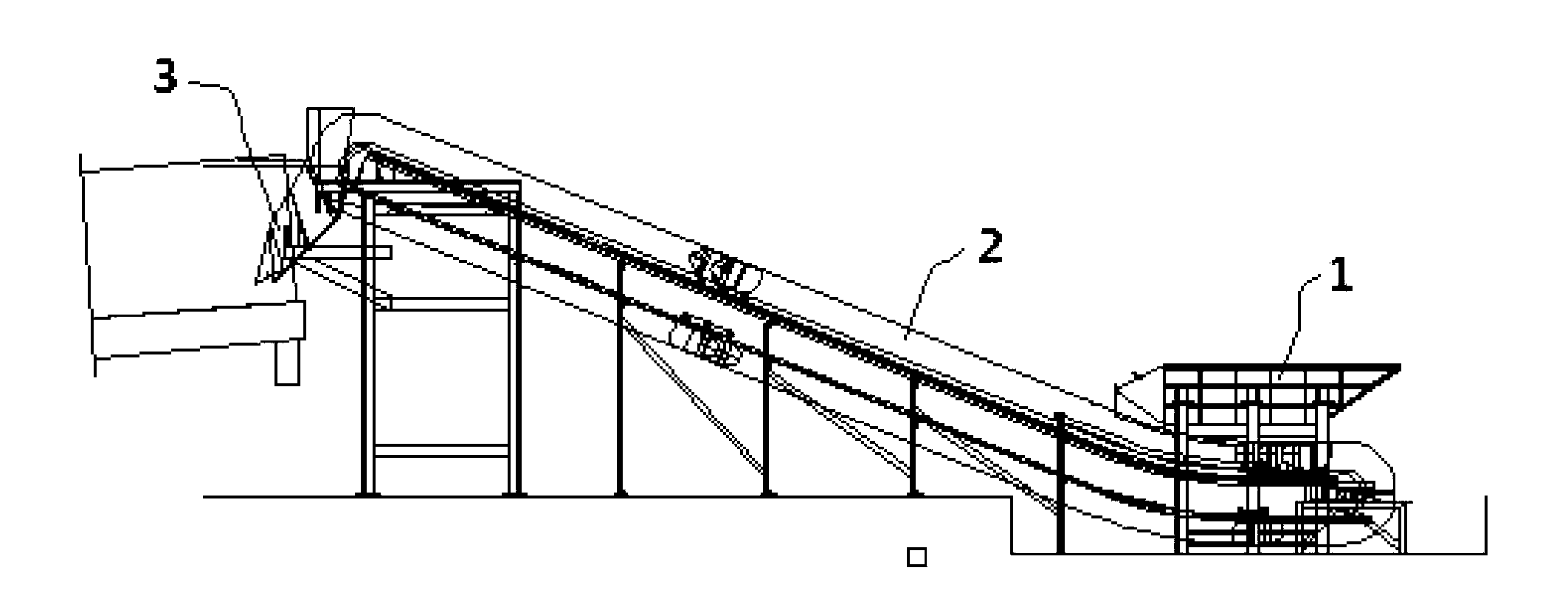

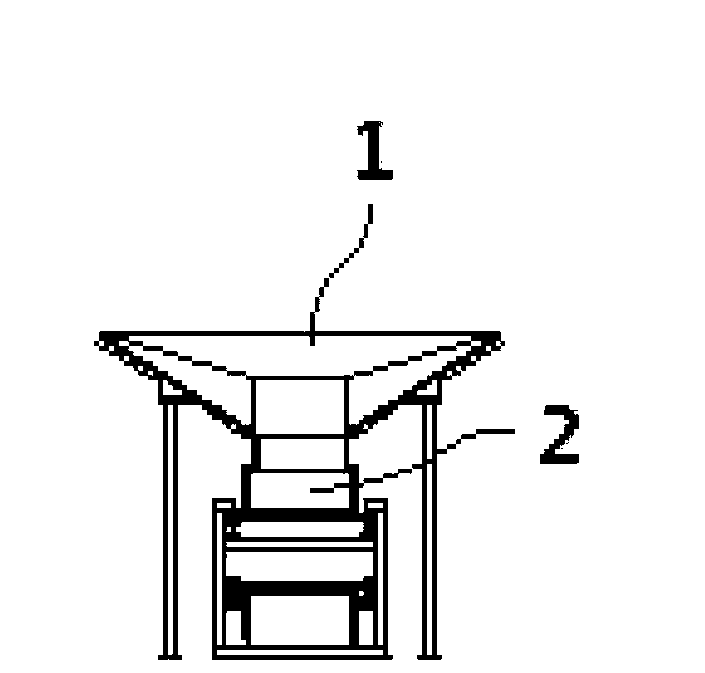

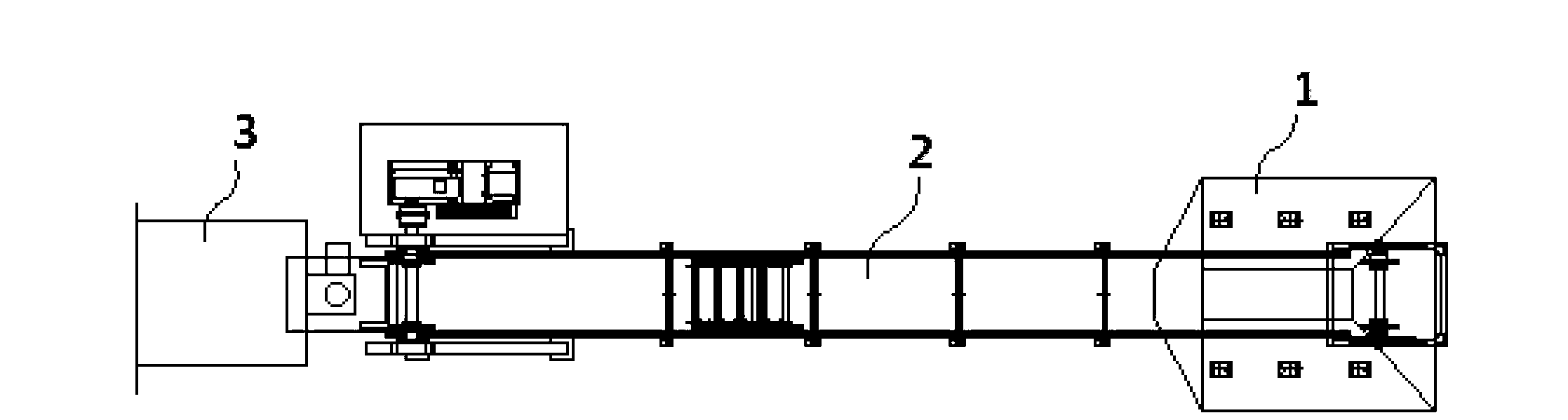

[0024] Such as figure 1 , figure 2 , image 3 As mentioned above, in one embodiment of the chain-plate conveyor system for conveying waste copper according to the present invention, the chain-plate conveyor system includes an upper hopper 1, a chain-plate conveyor 2, a discharge chute, a discharge chute, And the lower hopper 3, the upper hopper 1 is located at the lower end of the chain conveyor 2, and the discharge chute is located at the upper end of the chain conveyor 2.

[0025] The chain plate conveyor 2 has a material support chain plate and a chain bucket side chain plate. Both the material support chain plate and the chain bucket side chain plate have a series of chain plates. The tail of the previous chain plate covers the hinge of the next chain plate along the conveying direction. The inclination angle of the chain plate conveyor 2 can be 0°-60° °, preferably 10°-45°, more preferably 20°-25°.

[0026] The upper hopper 1 is in the shape of a quadrangular pyramid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com