Circuit breaker

A circuit breaker and arc extinguishing chamber technology, which is applied in the field of circuit breaker equipment, can solve the problems of large overall size of the arc extinguishing chamber, and achieve the effect of compactness, good elasticity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

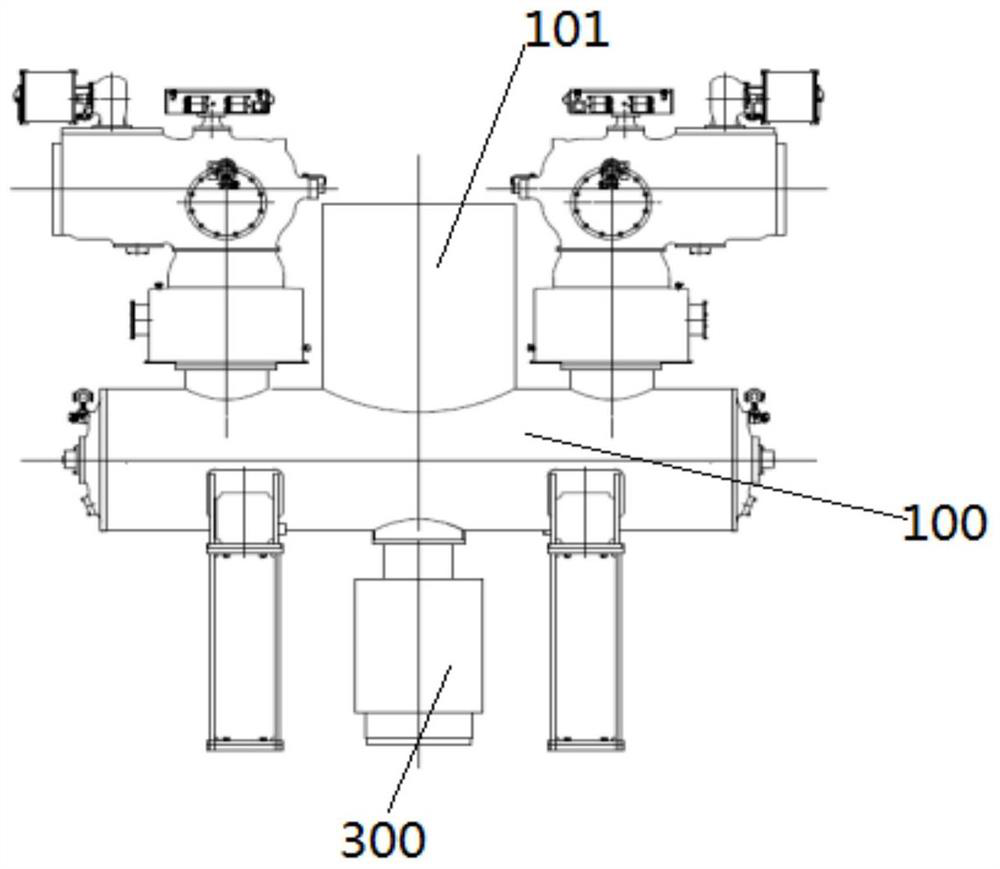

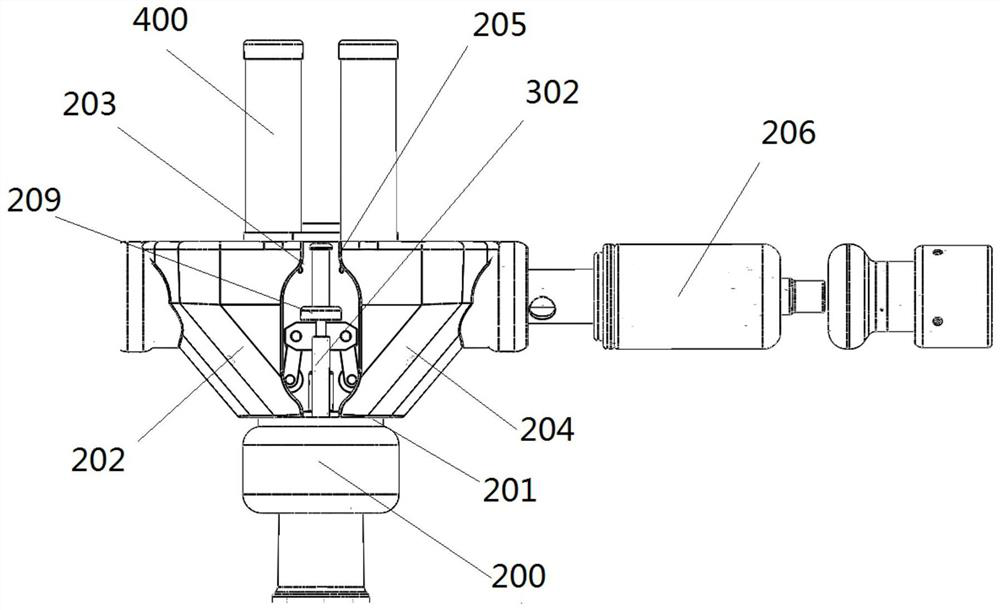

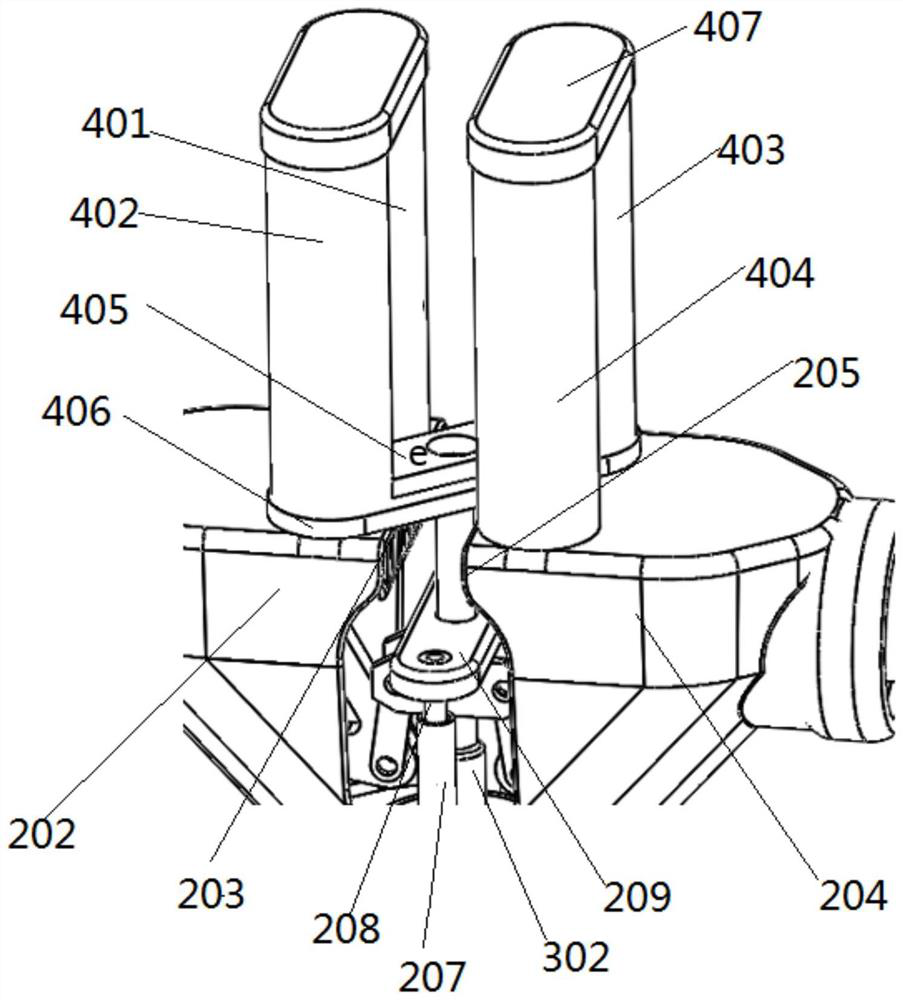

[0041] like figure 1 and figure 2 As shown, the circuit breaker provided in this embodiment is a double-break circuit breaker, and the circuit breaker includes an arc-extinguishing chamber cylinder 100 and an operating mechanism 300 , and the operating mechanism 300 includes a movable support arranged in the arc-extinguishing chamber cylinder 100 . 200 and the insulating pull rod 301, two arc extinguishing chambers are also installed in the arc extinguishing chamber cylinder 100, the two arc extinguishing chambers are supported on the movable support 200 by the support structure, and a closing resistor 400 is connected between the two arc extinguishing chambers, The arc extinguishing chamber cylinder 100 is also provided with a closing resistance static contact and a closing resistance moving contact 209, and the insulating pull rod 301 is respectively connected with the arc extinguishing chamber and the closing resistance moving contact 209 through transmission components, s...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the reversing transmission member includes a crank arm and a connecting rod. In this embodiment, however, the reversing transmission member includes a push head, a sliding block and a reset elastic member. The push head is arranged on the driving member, the sliding block is arranged on the movable contact rod for pushing the active contact, and the sliding block is arranged on the movable contact rod for pushing the active contact. There is an inclined surface that cooperates with the ejector head, and a reset elastic member is arranged between the movable contact rod and the corresponding conductor; the following effects can be achieved. When the insulating rod goes up, the ejector head on the driving member pushes the corresponding The slider, the slider drives the corresponding movable contact rod to complete the closing of the arc extinguishing chamber. At this time, the reset elastic m...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the resistor body extends in the up-down direction. However, in this embodiment, the extending direction of the resistor body is consistent with the extending direction of the arc extinguishing chamber cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com