Electric vehicle

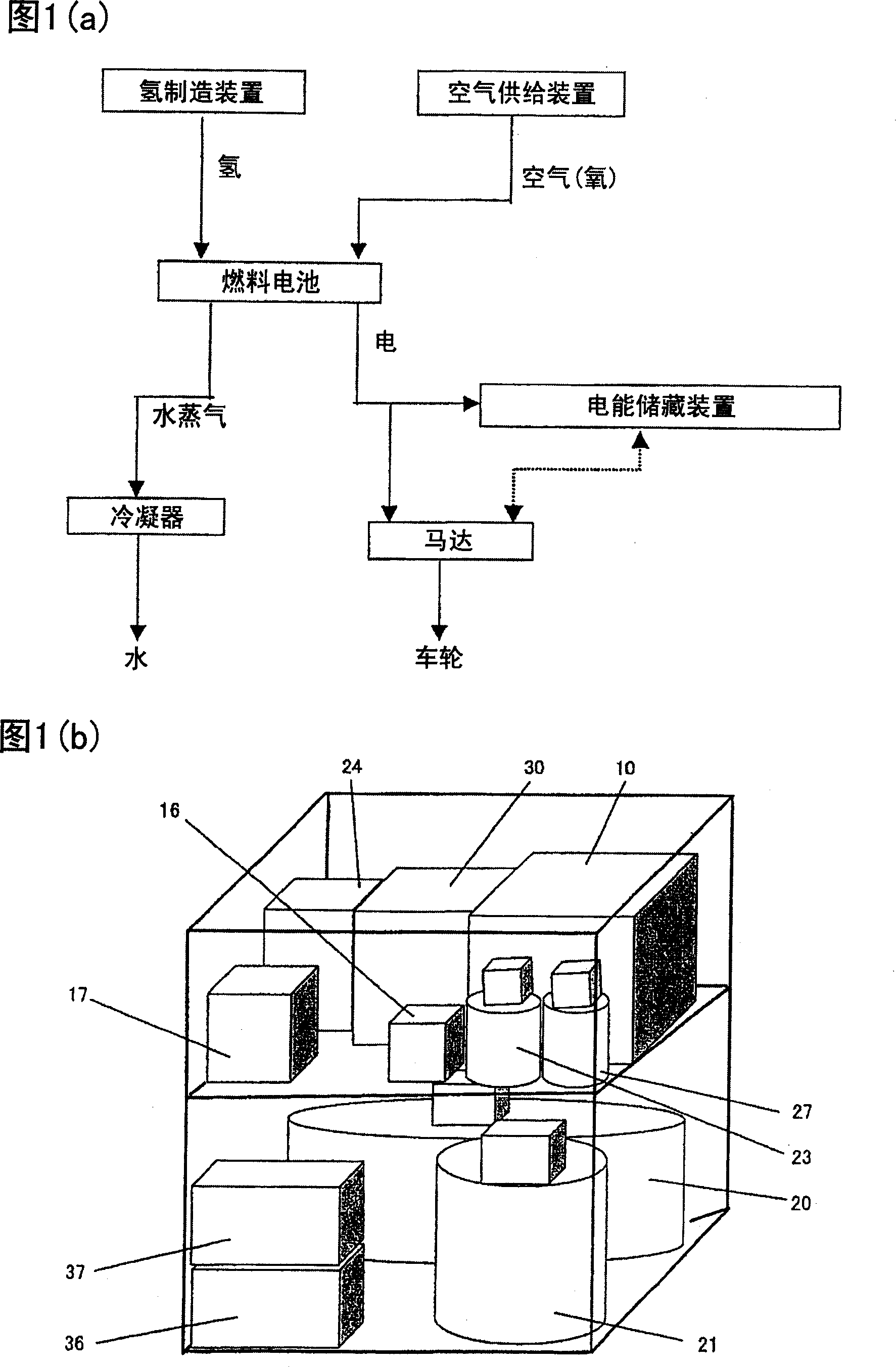

An electric vehicle and voltage technology, applied in electric vehicles, circuits, fuel cells, etc., can solve the problems of difficult hydrogen operation, poisoning of reforming catalysts, and difficult to achieve, and achieve the effect of reducing energy, shortening time, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

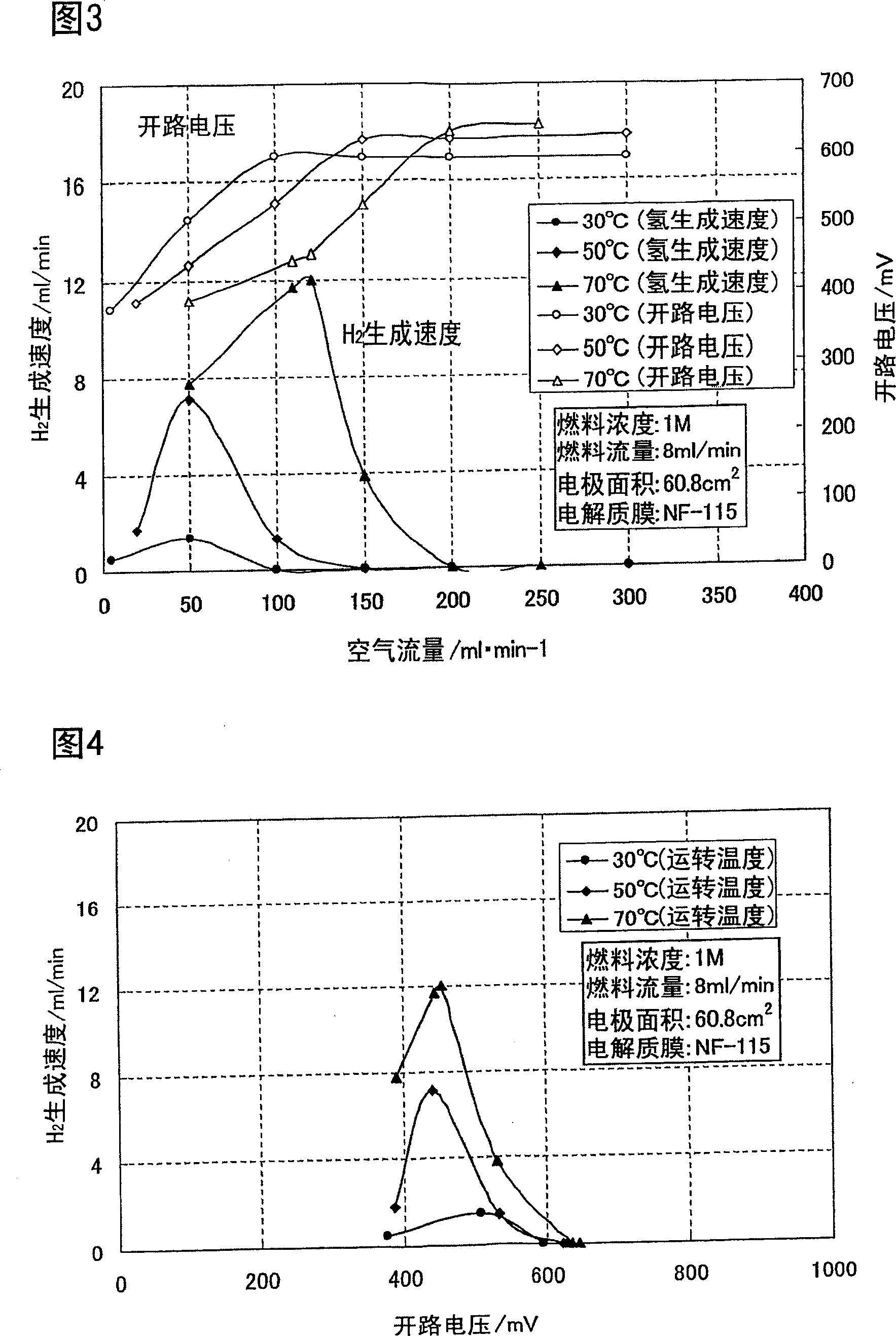

[0249]An example of the case where hydrogen is produced by the hydrogen production device (open circuit condition) used in the electric vehicle according to the invention according to claim 2 of the present application is shown below.

manufacture example 1-1

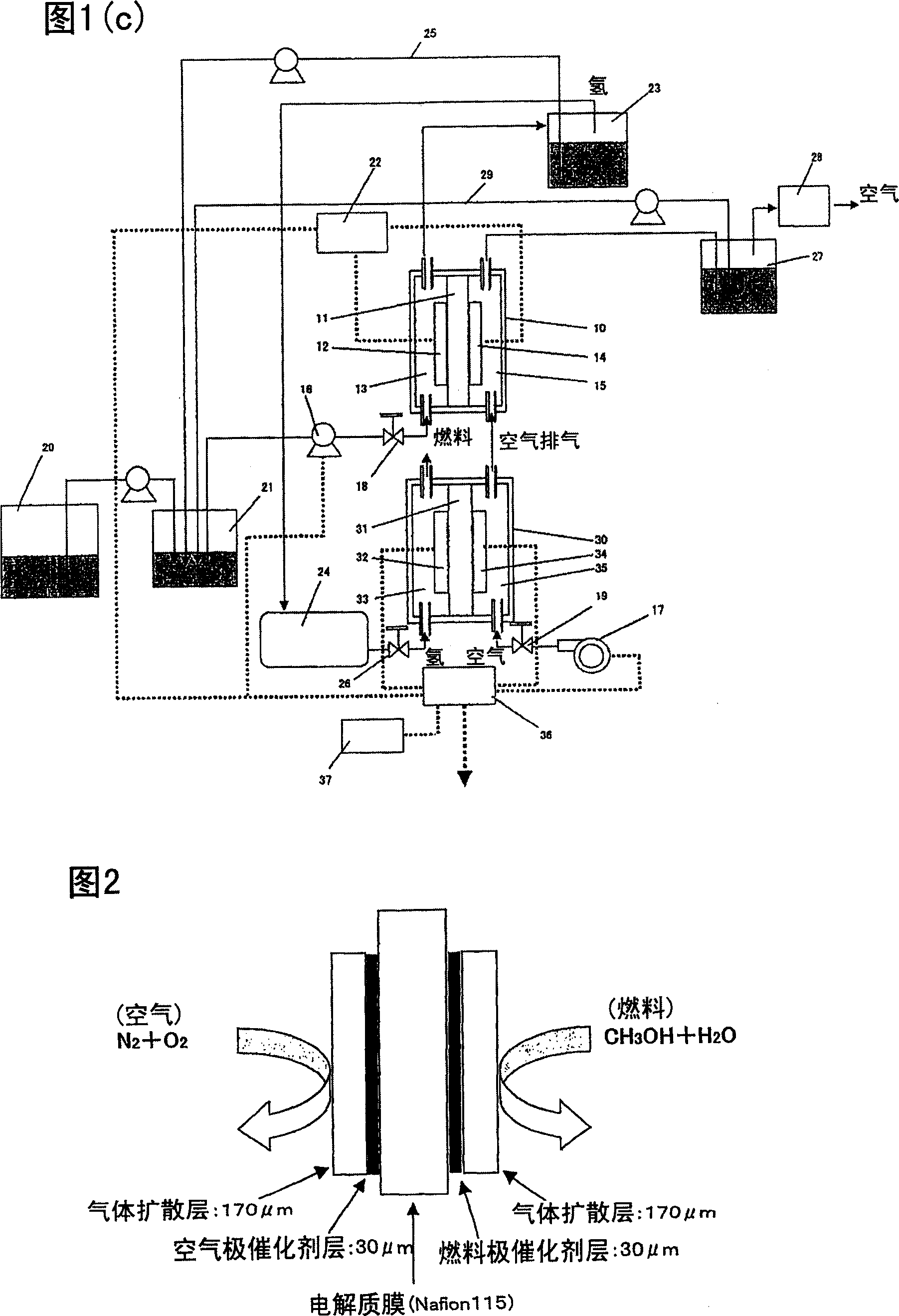

[0251] The hydrogen producing cells in Example 1 (Manufacturing Examples 1-1 to 1-10) had the same structure as a typical direct methanol fuel cell.

[0252] The outline of this hydrogen production cell is shown in FIG. 2 .

[0253] That is, using a proton conductive electrolyte membrane (Nafion 115) manufactured by DuPont Co., Ltd. as an electrolyte, carbon paper (manufactured by Toray) was immersed in a 5% concentration polytetrafluoroethylene dispersion, and then fired at 360° C. to perform hydrophobic treatment. One surface thereof is coated with an air electrode catalyst slurry by mixing an air electrode catalyst (platinum-carrying carbon, manufactured by Tanaka Kikinzoku Co., Ltd.) to form a gas diffusion layer with an air electrode catalyst on the air electrode. ), PTFE fine powder and 5% Nafion solution (manufactured by Aldrich). Here, the weight ratio of the air electrode catalyst, PTEF, and Nafion is 65%:15%:20%. The amount of catalyst in the air electrode produced...

manufacture example 1-2

[0266] Use the same hydrogen production cell as in Hydrogen Production Example 1-1, and then change the air flow rate under the condition that the cell temperature is 70°C and the flow rate of methanol aqueous solution (fuel) with a concentration of 1M is 2, 8, and 15 ml / min, as shown in Fig. 5 The relationship between the fuel flow rate, the air flow rate, the hydrogen generation rate, and the open circuit voltage of the battery at this time is shown.

[0267] It can be seen that the hydrogen generation rate is high when the fuel flow rate is small.

[0268] The results of FIG. 5 are shown in FIG. 6 as a relationship between the open circuit voltage and the hydrogen generation rate.

[0269] From this, it can be seen that the hydrogen generation rate under each condition depends on the open circuit voltage. In addition, at any of the fuel flow rates, as in Hydrogen Production Example 1-1, a peak of the hydrogen production rate was observed around 450 mV.

[0270] Furthermor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com