Horizontal grinding type grain milling machine

A grain milling machine and horizontal type technology, applied in grain processing, grain pod removal, grain shelling, etc., can solve the problems of low filling degree, grain temperature rise, etc., to prevent uneven grinding, eliminate blockage, and prevent crushing The effect of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

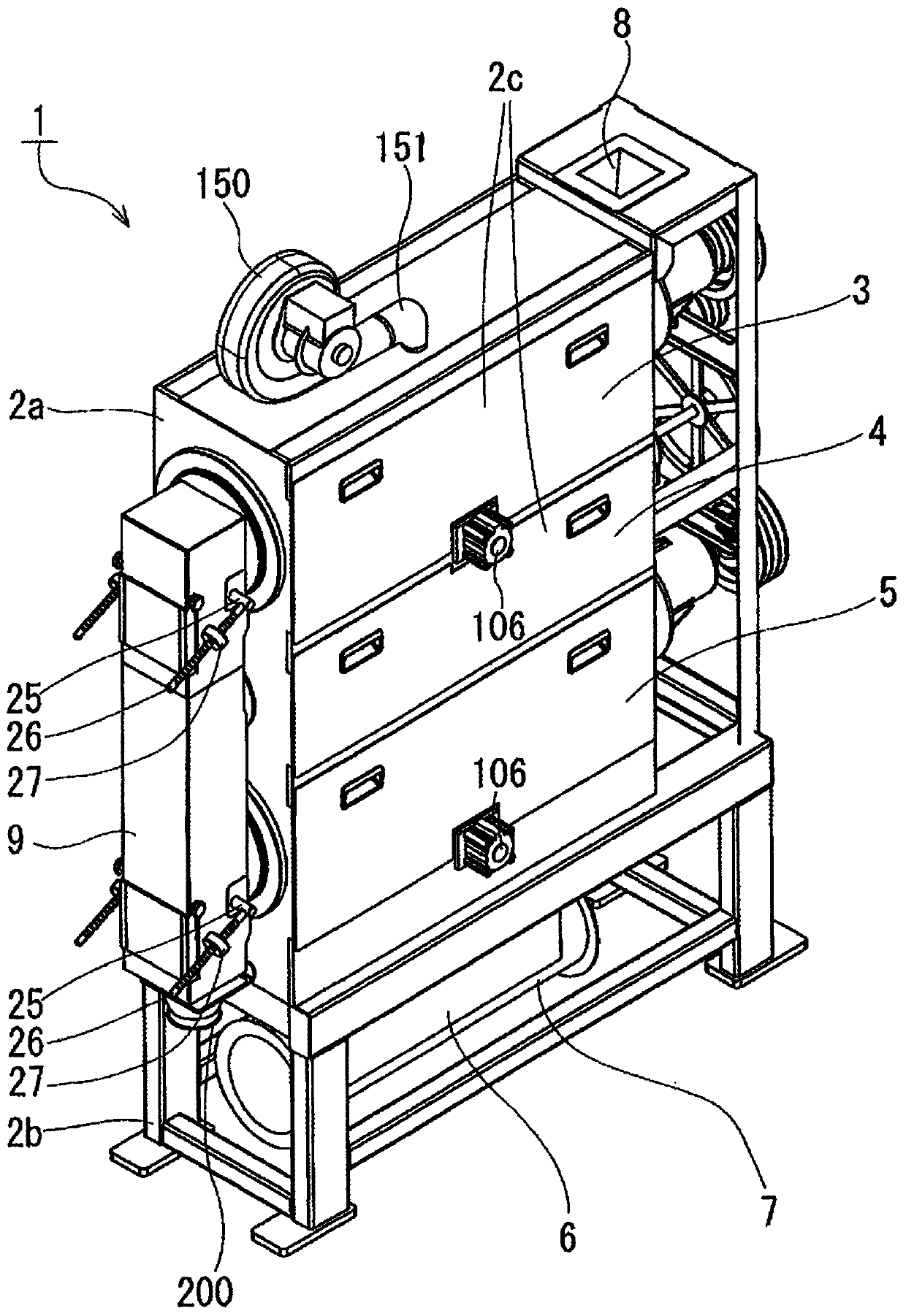

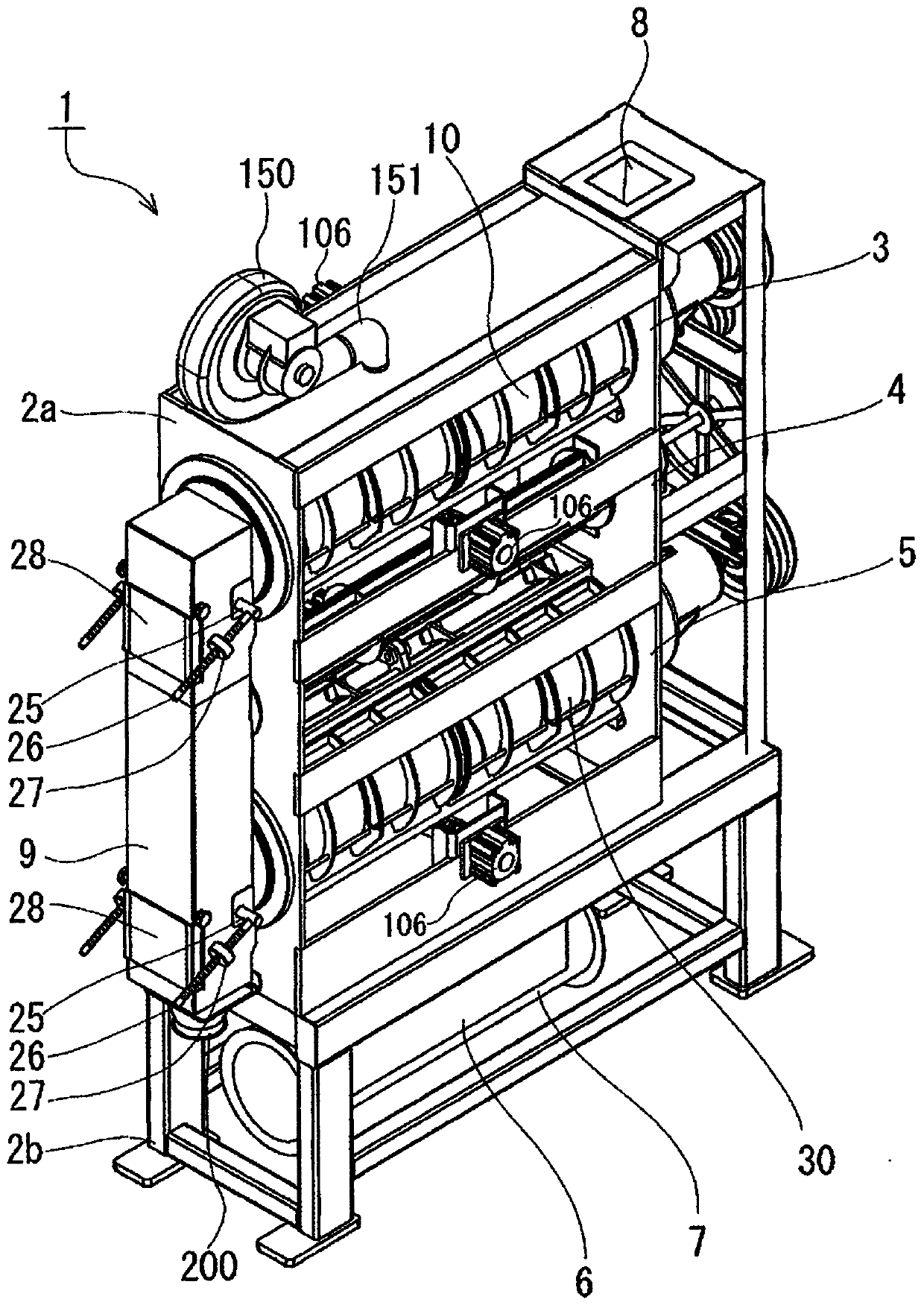

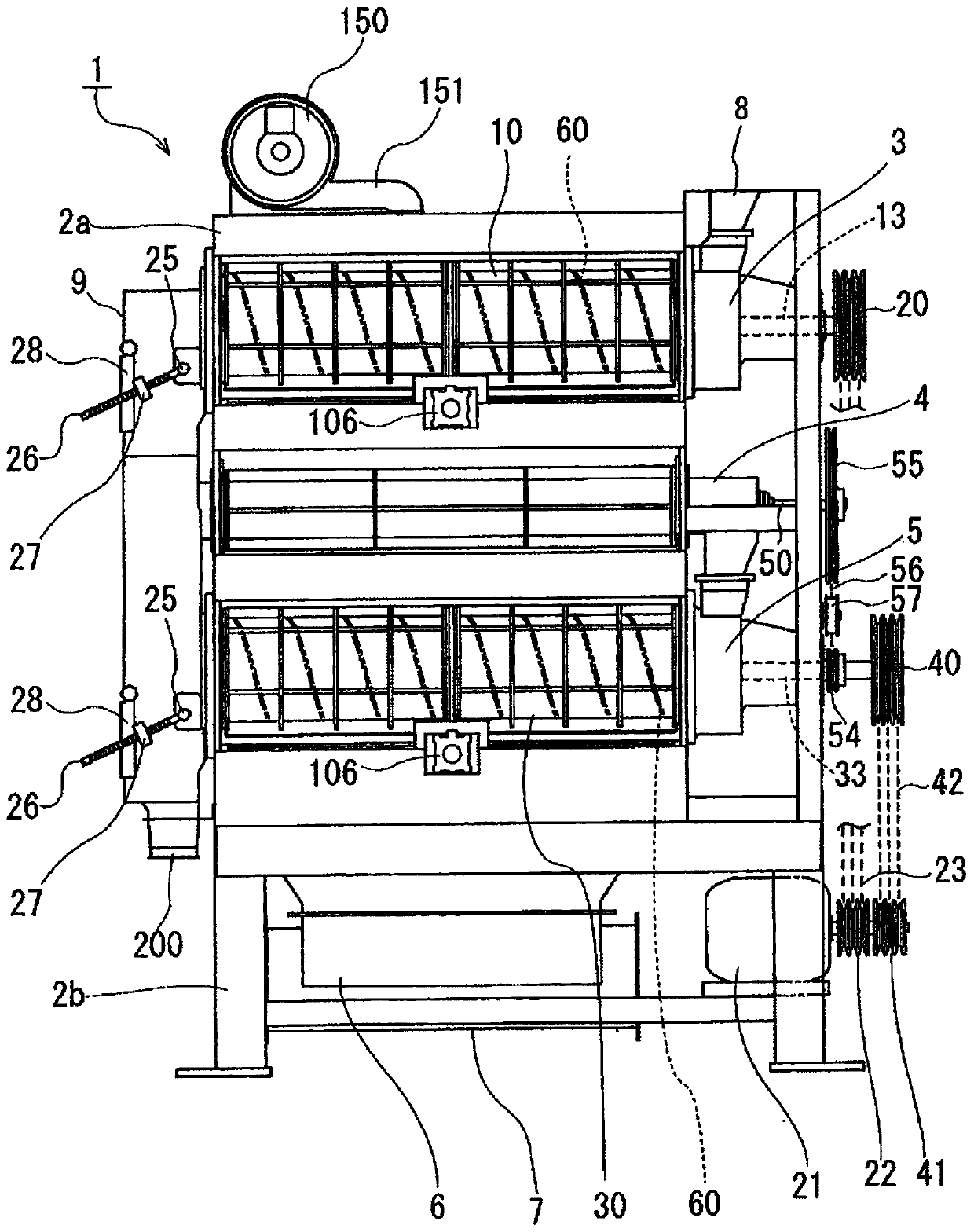

[0052] Hereinafter, preferred embodiments of the present invention will be described based on the drawings. figure 1 It is a schematic perspective view showing the appearance of the horizontal grinding mill of the present invention, figure 2 It is a perspective view when the mill cover is removed to reveal the white mill barrel, image 3 Yes figure 2 A rough front view of the , Figure 4 It is a schematic longitudinal sectional view showing the internal structure.

[0053] like Figure 1 to Figure 4As shown, the horizontal grinding type rice milling machine 1 of an embodiment of the present invention mainly includes: the first horizontal grinding type rice milling machine 3 arranged on the top of the elongated box-shaped frame 2a; The screw conveyor 4 arranged at the lower position of the above-mentioned grinding type rice milling machine 3; The first grinding mill 3 , the screw conveyor 4 and the second milling mill 5 are integrally arranged side by side in parallel up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com