Punching and grinding integrated device

A punching and integrated technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of unsightly appearance, complicated operation, and affecting the quality of use, so as to save energy and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

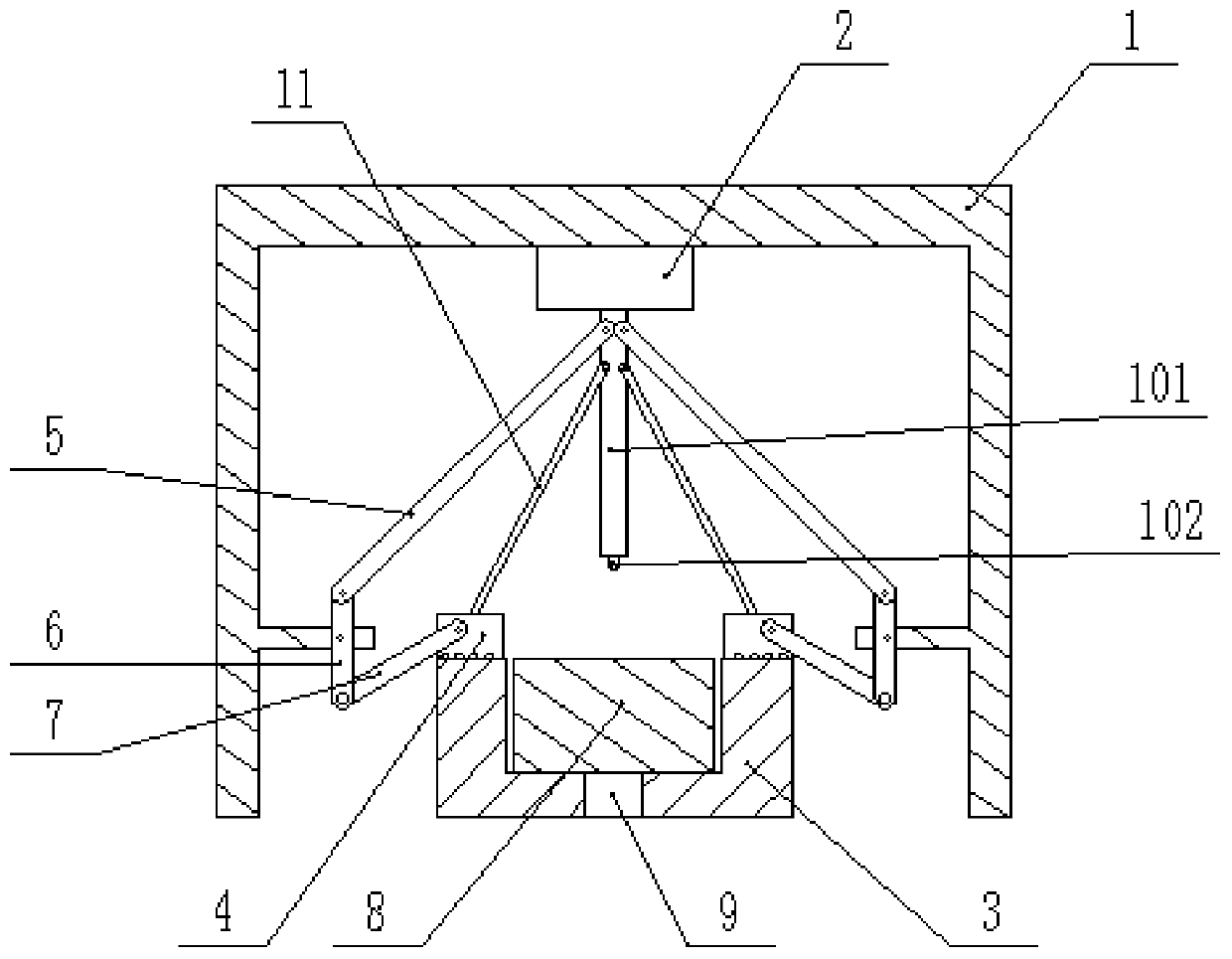

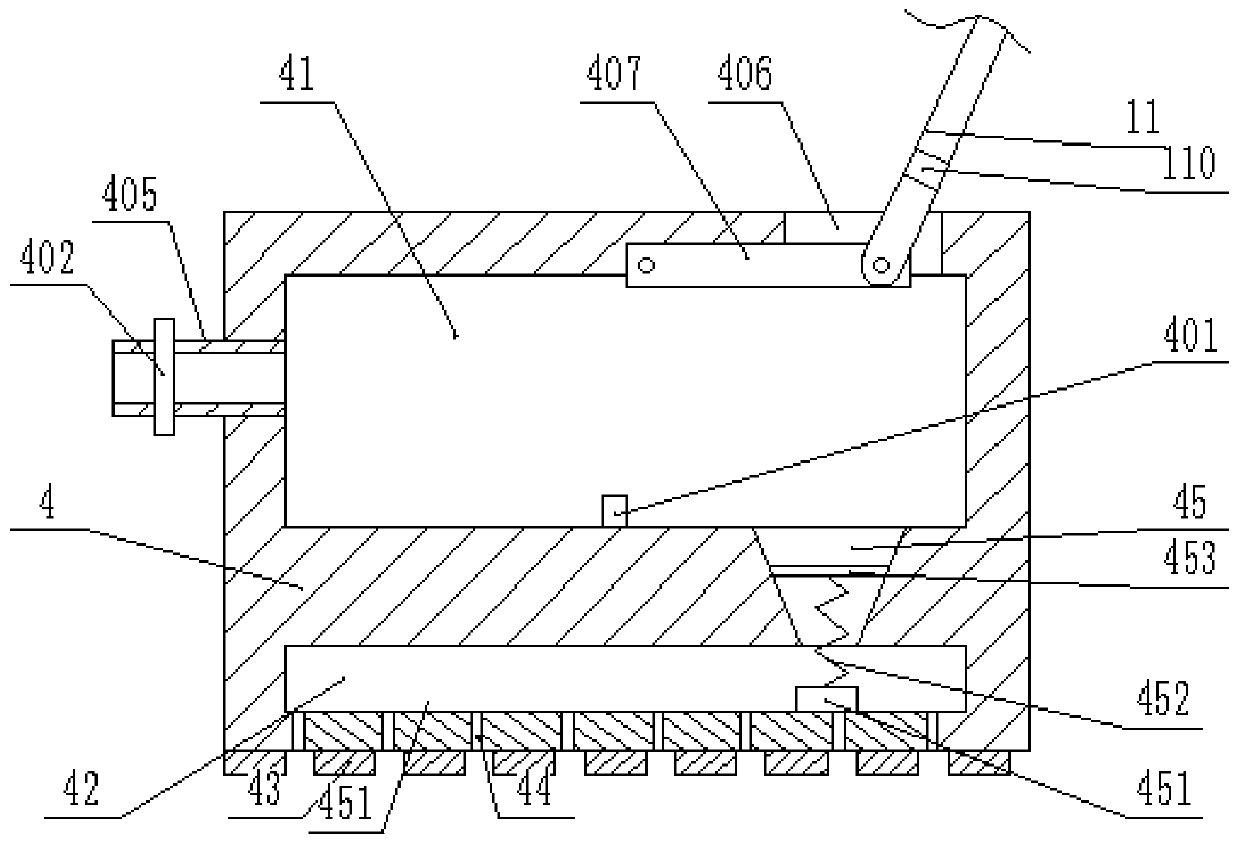

[0023] The reference signs in the drawings of the description include: frame 1, punch rod 101, punch 102, drive magnet 110, cylinder 2, fixed sleeve 3, grinding block 4, housing chamber 41, stopper 401, valve 402, water inlet pipe 405, push hole 406, partition 407, water outlet cavity 42, grinding protrusion 43, water outlet hole 44, communication hole 45, fixed block 451, supporting spring 452, moving magnet 453, first connecting rod 5, second connecting rod 6 , The third connecting rod 7, the workpiece 8, the chip hole 9, the push rod 11.

[0024] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0025] The punching and polishing integrated device includes a frame 1, and also includes a punching machine, a grinding machine and a fixed sleeve 3 arranged in sequence from top to bottom. The fixed sleeve 3 is provided with a positioning groove. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com