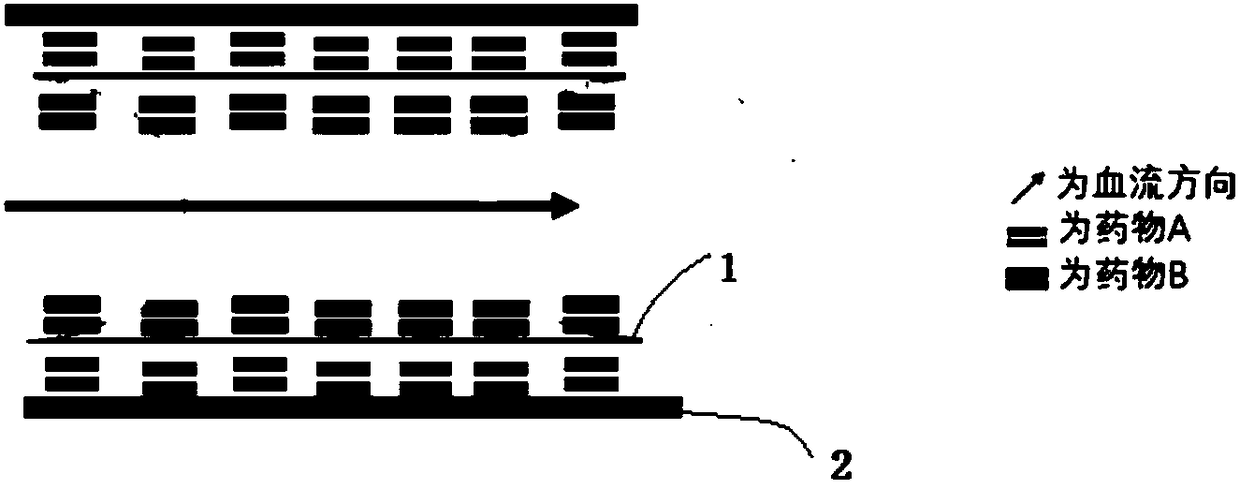

Bidirectional double-drug eluting stent and preparation method thereof

An eluting stent and dual-drug technology, applied in the field of eluting stents, can solve problems such as lumen loss, stent thrombosis, and stent stenosis, and achieve the effects of accelerating re-endothelialization, rapid endothelialization, and delayed endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The selected base stent is a cobalt alloy stent, and a solution with the following components is configured: the carrier material is polylactic acid, the solvent of atorvastatin is a mixed solvent of acetone and ether (mass ratio 2:8), and the solvent of tacrolimus is chloroform Mixed solvent with ethanol (mass ratio 1:1).

[0024] Polylactic acid (Mn=50000) 0.1g

[0025] Atorvastatin 1mg

[0026] Tacrolimus 20mg

[0027] Acetone 20ml + ether 80ml

[0028] Chloroform 50ml+ and ethanol 50ml

[0029] Mix the above systems separately and stir at 10 rpm to form a solution.

[0030] Clean the cobalt alloy stent and place it on an ultrasonic atomization sprayer. First, spray the atorvastatin / polylactic acid solution on the inside of the stent. The ultrasonic power is 0.1W, the solution flow rate is 0.01ml / min, and the number of sprays is 10 times. Finish drying at room temperature for 0.1 hour, and then spray tacrolimus / polylactic acid solution on the outside of the sten...

Embodiment 2

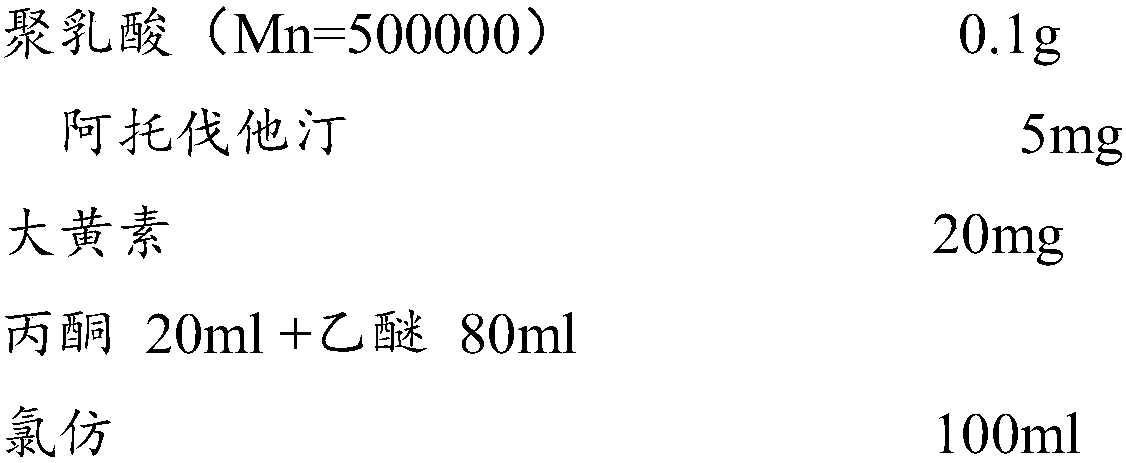

[0032] The selected substrate stent is a cobalt alloy stent, and a solution with the following components is configured: the carrier material is polylactic acid, the solvent of atorvastatin is a mixed solvent of acetone and ether (mass ratio 2:8), and the solvent of emodin is chloroform.

[0033]

[0034] Mix the above systems separately and stir at 300rpm to form a solution.

[0035] Clean the cobalt alloy stent and place it on an ultrasonic atomization sprayer. First, spray the atorvastatin / polylactic acid solution on the inside of the stent. The ultrasonic power is 20W, the solution flow rate is 0.5ml / min, and the number of sprays is 20 times. The spraying is completed. Dry at room temperature for 4 hours, and then use an ultrasonic atomization sprayer to spray the emodin / polylactic acid solution on the outside of the bracket. The ultrasonic power is 20W, the solution flow rate is 0.1ml / min, and the number of sprays is 30 times. After spraying, put the bracket on the Vac...

Embodiment 3

[0037] The selected base stent is a magnesium alloy stent, and a solution with the following components is configured: the carrier material of fluvastatin is polylactic acid-glycolic acid copolymer, and the solvent of fluvastatin is a mixed solvent of tetrahydrofuran and ether (mass ratio 9:1); The carrier material of mycin is polyglycolic acid, and the solvent is acetone.

[0038]

[0039] Mix the above systems separately and stir at 600rpm to form a solution.

[0040] Clean the magnesium stent and place it on an ultrasonic atomization sprayer. First, spray the fluvastatin / polylactic acid-glycolic acid copolymer solution on the inside of the stent. The ultrasonic power is 10W, the solution flow rate is 0.1ml / min, and the number of sprays is 40 times. After spraying, dry at room temperature for 4 hours, and then use an ultrasonic atomization sprayer to spray the rapamycin / polyglycolic acid solution on the outside of the bracket. The ultrasonic power is 10W, the solution flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com