Premixed magnesium phosphate-based dental filling material with stable suspension as well as preparation method and application thereof

A magnesium phosphate-based dental and filling material technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of long coagulation time, fast hydration reaction speed, and troublesome preparation, and achieves insignificant reaction temperature rise and coagulation time. Long, doctor-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of suspension stable pre-mixed magnesium phosphate based dental filling material 1

[0030] (1) Weigh the raw materials according to the following weight percentages: (a) 21% of dead-burned magnesium oxide; (b) 23% of potassium dihydrogen phosphate; (c) 37% of zirconium oxide and (d) 19% of polyethylene glycol;

[0031] (2) Put the components of step (1) into a glass container one by one, use a stainless steel stirring rod for mechanical mixing, and fully adjust for 5 minutes;

[0032] (3) Afterwards, the mixed paste is transferred to a medical syringe equipped with an injection hose needle to obtain a suspension and stable pre-mixed magnesium phosphate-based dental filling material.

[0033] The material is kept fluid under a sealed condition, extruded samples are placed in a constant temperature and humidity cabinet at 37°C and 95% humidity (or filled to the teeth in contact with physiological body fluids), hydration and hardening, hydration and hardening...

Embodiment 2

[0034] Example 2 Preparation of suspension stable pre-mixed magnesium phosphate based dental filling material 2

[0035] (1) Weigh the raw materials according to the following weight percentages: (a) Light burnt magnesium oxide 9%; (b) Sodium dihydrogen phosphate 12%; (c) Bioglass 63S 10%; (d) Anhydrous calcium dihydrogen phosphate 15%; and (e) tantalum oxide 33% (f) polyethylene glycol 21%;

[0036] (2) Put the components of step (1) into a glass container one by one, use a stainless steel stirring rod for mechanical mixing, and fully adjust for 5 minutes;

[0037] (3) Afterwards, the mixed paste is transferred to a medical syringe equipped with an injection hose needle to obtain a suspension and stable pre-mixed magnesium phosphate-based dental filling material.

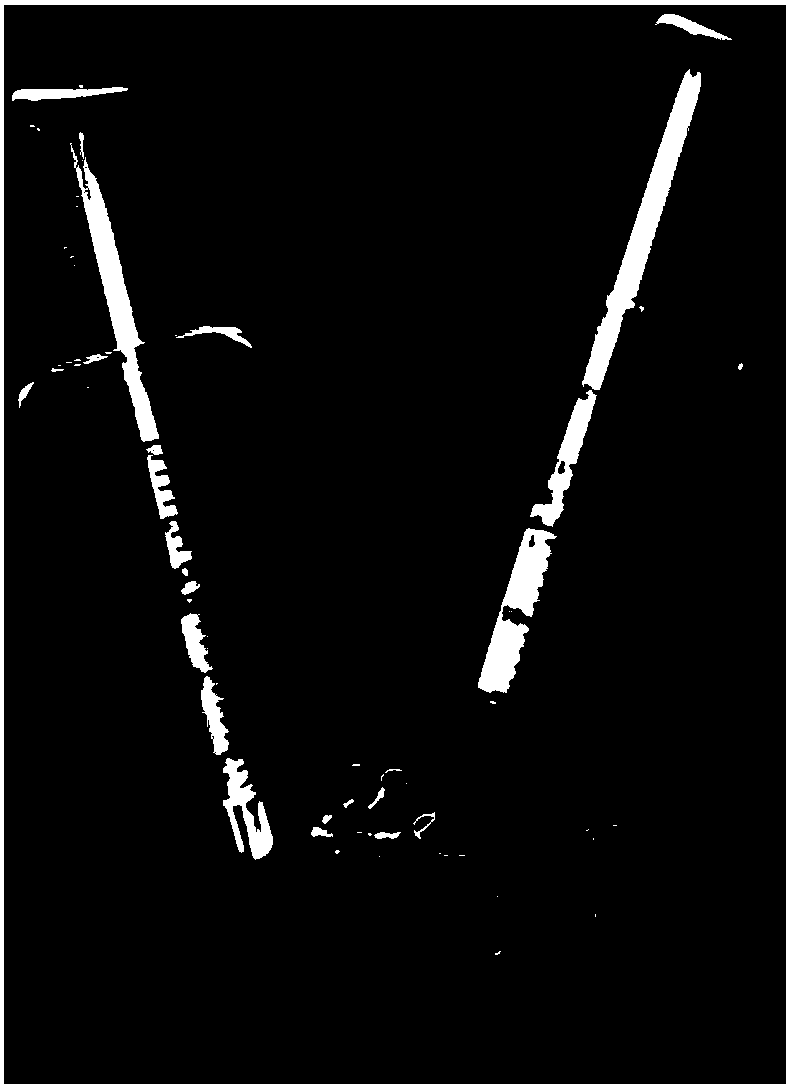

[0038] figure 1 This is a photograph of the sample obtained in Example 2. The material is kept fluid under sealed conditions, and the extruded sample is placed in a constant temperature and humidity cabinet with a humidit...

Embodiment 3

[0039] Example 3 Preparation of a suspension stable pre-mixed magnesium phosphate-based dental filling material 3

[0040] (1) Weigh the raw materials according to the following weight percentages: (a) 7% of dead-burned magnesium oxide; (b) 7% of ammonia dihydrogen phosphate; (c) 20% of calcium dihydrogen phosphate; (d) 35 bismuth trioxide % And (e) 31% glycerol.

[0041] (2) Put the components of step (1) into a glass container one by one, use a stainless steel stirring rod for mechanical mixing, and fully adjust for 5 minutes;

[0042] (3) Afterwards, the mixed paste is transferred to a medical syringe equipped with an injection hose needle to obtain a suspension and stable pre-mixed magnesium phosphate-based dental filling material.

[0043] The material is kept fluid under sealed conditions, and the extruded samples are placed in a constant temperature and humidity cabinet with a humidity of over 95% at 37°C (or when the teeth are filled with physiological body fluids), hydrated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com