Automatic diagnosis and data monitoring system for commercial dish-washing machine

A data monitoring system and automatic diagnosis technology, applied in the direction of digital transmission system, transmission system, data exchange network, etc., can solve the problem that the operator's improper operation is difficult to be found and corrected, the maintenance personnel cannot analyze the cause of the fault, and the online upgrade is impossible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An embodiment of the present invention provides an automatic diagnosis and data monitoring system for commercial dishwashers to solve the following technical problems:

[0061] (1) Dishwashers and maintenance personnel are not easy to detect when the dishwasher is not working properly.

[0062] The dishwasher is almost closed when washing dishes, and the operator cannot directly see the washing process. Problems with the heating tube lead to insufficient water temperature, too much or too little detergent injected, and too little water sprayed during rinsing, resulting in failure to rinse off the residual detergent on the tableware. These problems are difficult to be solved by operators and maintenance personnel. personnel found. Many dishwashers do not work properly for these reasons and can pose food hygiene safety hazards.

[0063] (2) Improper operation of the operator is difficult to be found and corrected.

[0064] Some operators do not operate standardly when ...

Embodiment 2

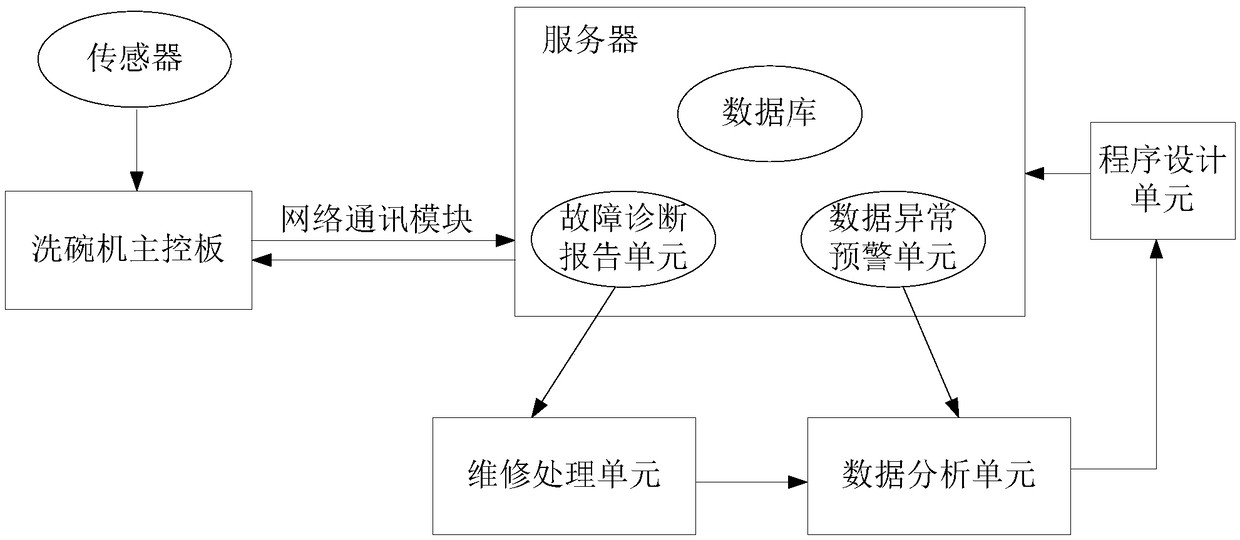

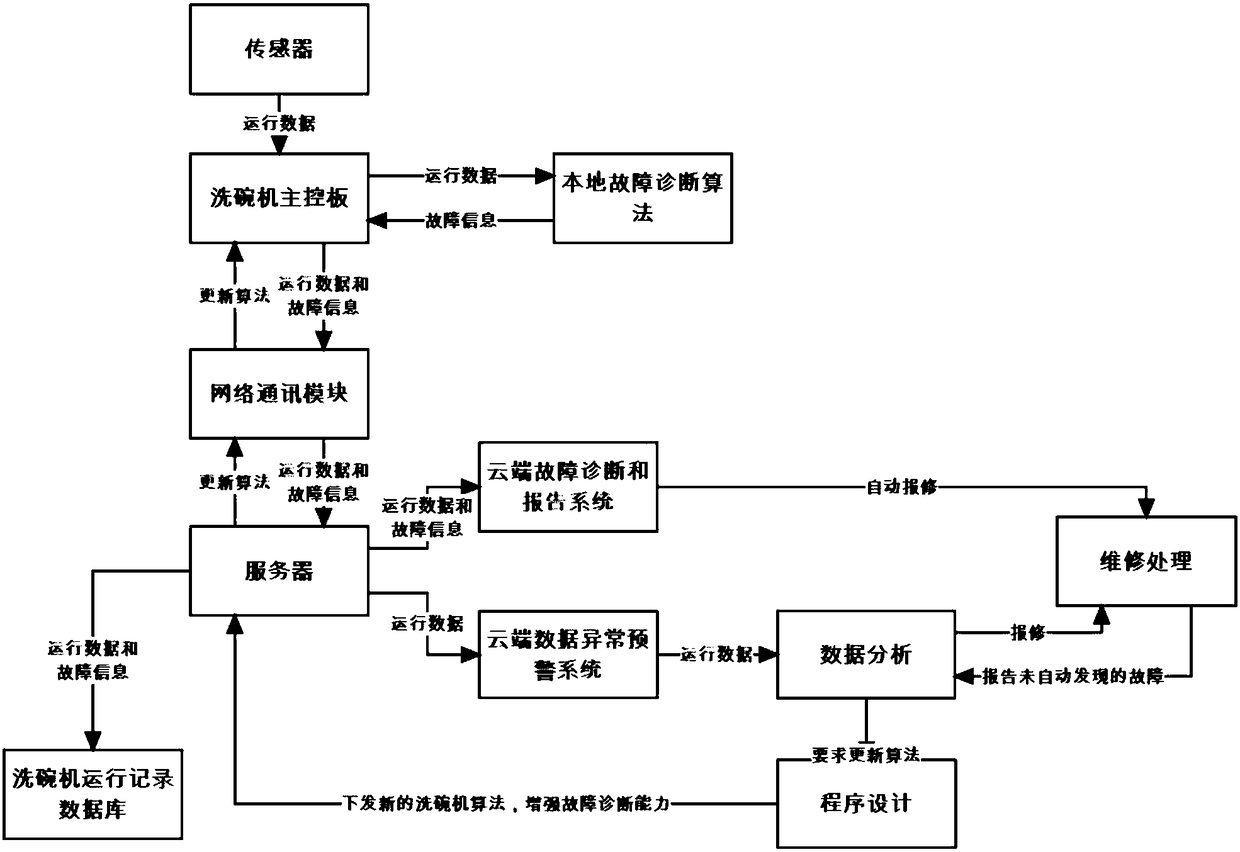

[0122] This embodiment provides an automatic diagnosis and data monitoring system for commercial dishwashers, the data upload and analysis flow chart of the system is as follows figure 2 As shown, it can specifically include the following modules: sensors, dishwasher main control board, network communication module, server, maintenance processing, data analysis and program design; according to the system, the operation data of the dishwasher can be comprehensively analyzed to realize The cross-validation of the system determines the specific fault range.

[0123] The main control board of the dishwasher periodically collects data from various sensors, and at the same time runs a local fault diagnosis algorithm to determine whether the dishwasher is currently faulty. The main control board sends all operating data and fault information (if a fault is found) to the server via the network communication module of the dishwasher.

[0124] On the one hand, the server stores all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com