Rotor punching sheet for permanent-magnet motor of electric vehicle

A technology of rotor punching and permanent magnet motors, which is applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of reducing reluctance torque components, low production efficiency, and reducing salient pole ratio, so as to reduce torque ripple, The effect of improving production efficiency and reducing harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

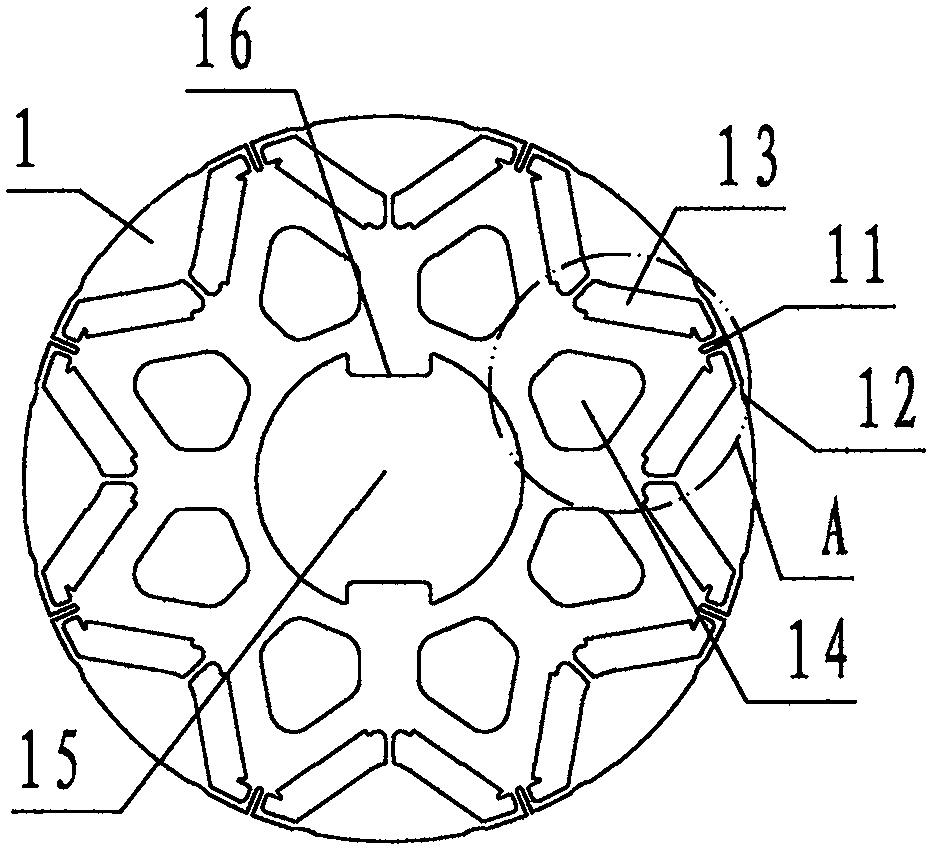

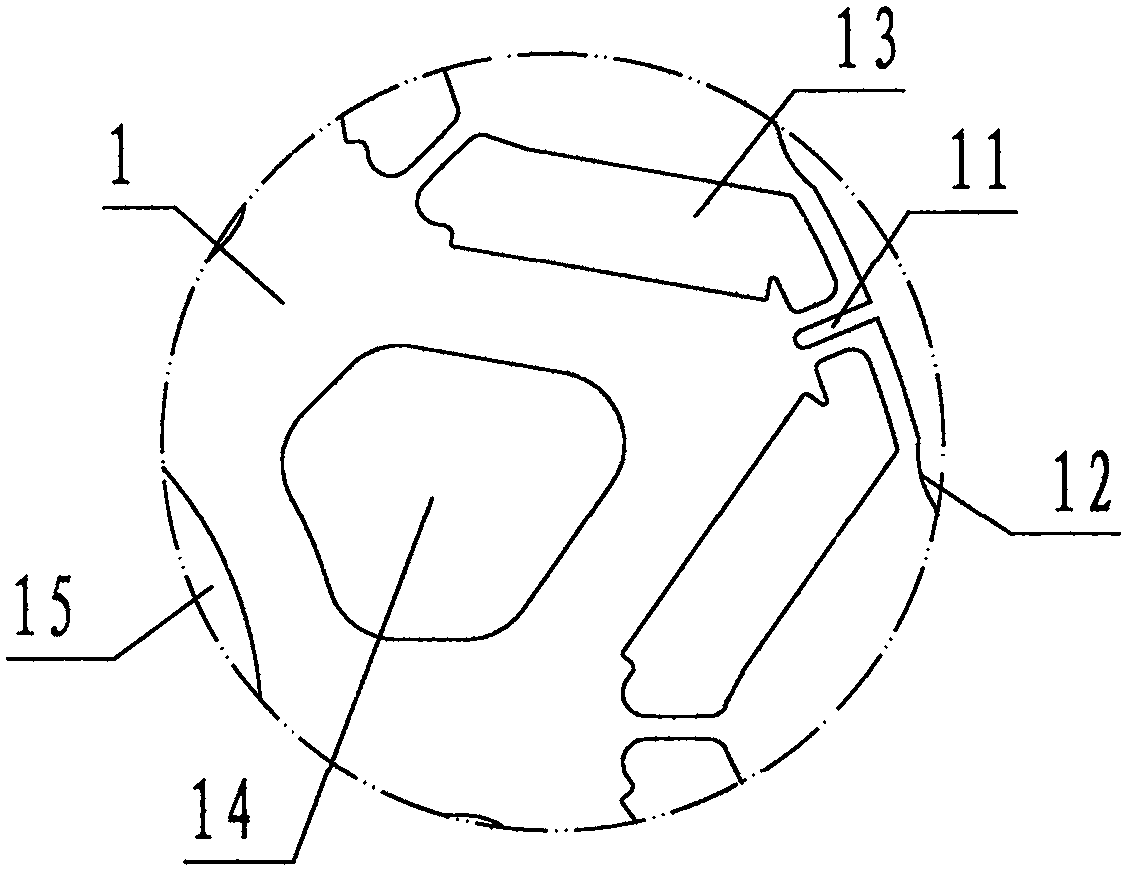

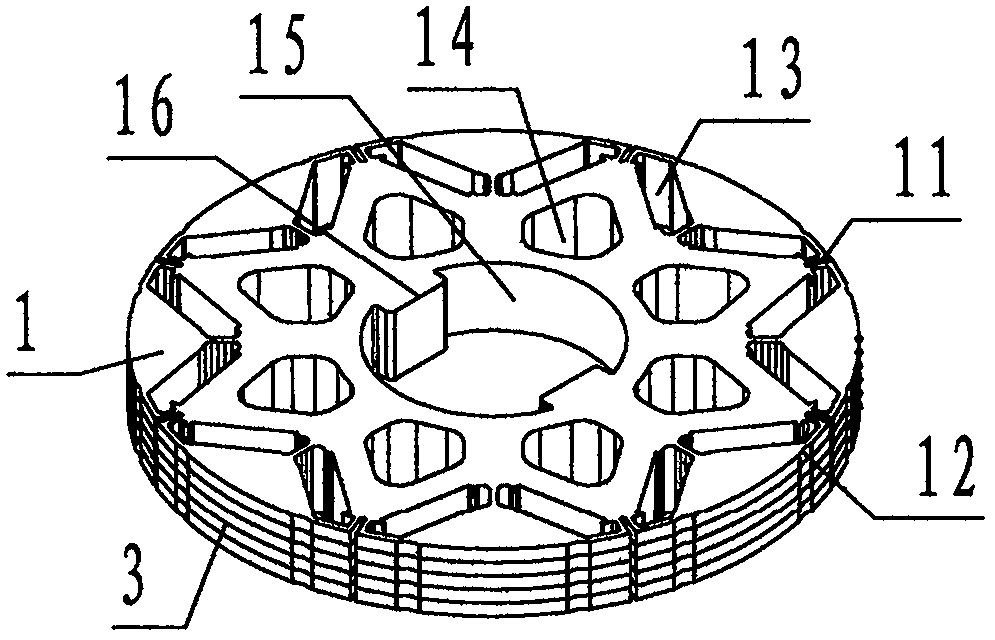

[0032] refer to Figure 1 ~ Figure 4 , a permanent magnet motor rotor punching sheet for an electric vehicle of the present invention, the rotor punching sheet is provided with a magnetic isolation groove 11, a magnetic gap notch 12, a permanent magnet hole 13, a weight reduction hole 14, a shaft hole 15 and a tenon key 16 The film base 1 is composed of; the film base 1 is an alloy permeable soft magnetic member with an insulating paint film and a circular thin sheet on the surface, and the center of the film base 1 is provided with a circular through hole called a shaft hole 15 , the upper and lower sides of the shaft hole 15 are provided with rectangular flanges called mortise keys 16; An octagonal star-shaped magnetic pole circle, the permanent magnet hole 13 is a rectangular through hole in the shape of a ∫ character; The through hole is called the weight-reducing hole 14; at the circumference of the base 1, there is a rectangular gap between two adjacent permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com