Maintainable alkaline zinc-manganese battery and maintaining method of alkaline zinc-manganese battery

A zinc-manganese battery and alkaline technology, which is applied in the field of alkaline zinc-manganese batteries, can solve problems such as battery leakage, high metal impurities, and affect customer brand confidence, so as to reduce loss, simplify the preparation process, and reduce battery leakage. effects of liquids or risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

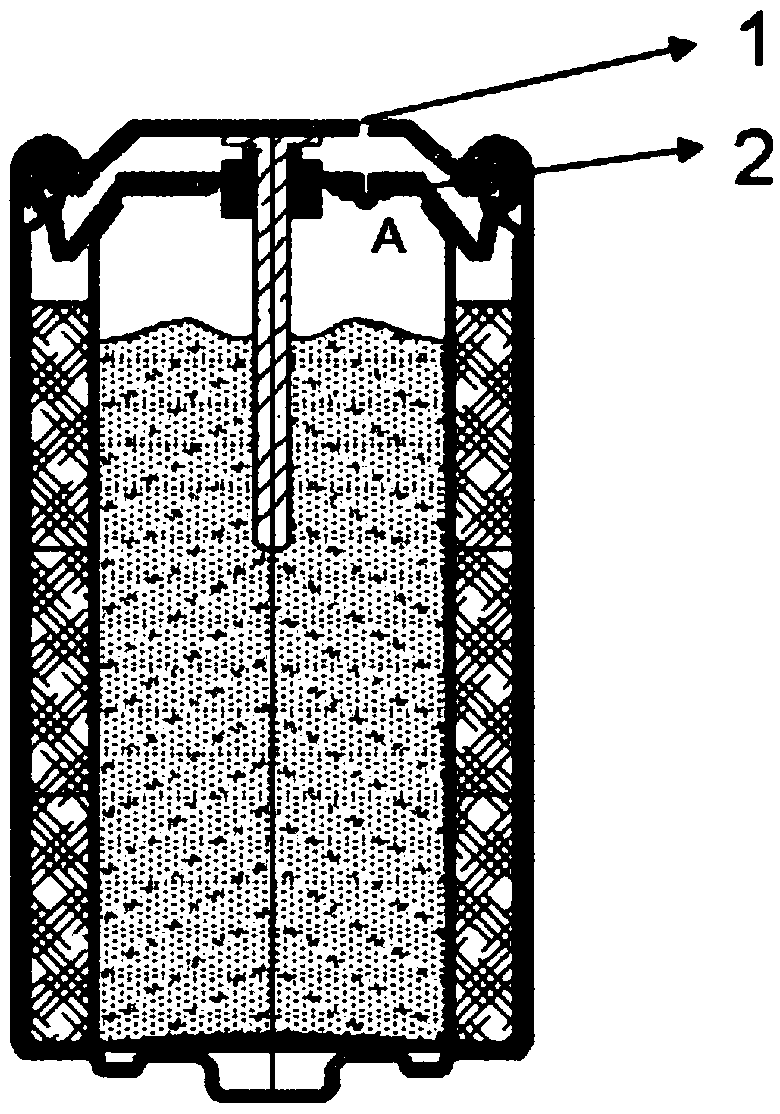

[0049] according to figure 1 Inlay the sealing ring with the reverse valve rubber block 2 made of natural rubber; stir the gel, electrolyte and zinc powder in a ratio of 1:50:100 to form a zinc paste, and then add 100ppm of iron impurities (calculated according to the mass of zinc powder ); through the FDK460 production line, after the positive electrode ring of the steel shell is embedded, the diaphragm paper is inserted, the zinc paste with impurities is injected, the current collector composed of copper nails, the bottom cover with through holes and the sealing ring containing the reverse valve is inserted, and the edge is shaped Sealing to obtain a maintainable LR6 battery;

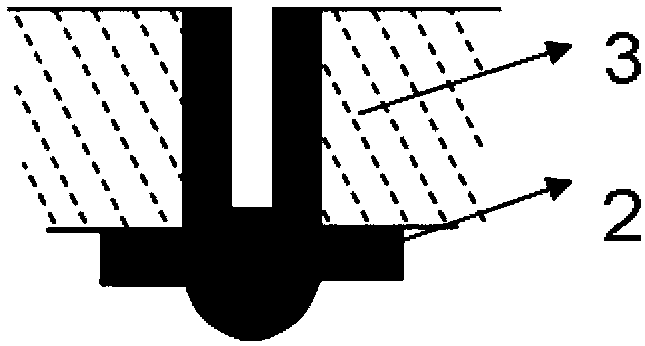

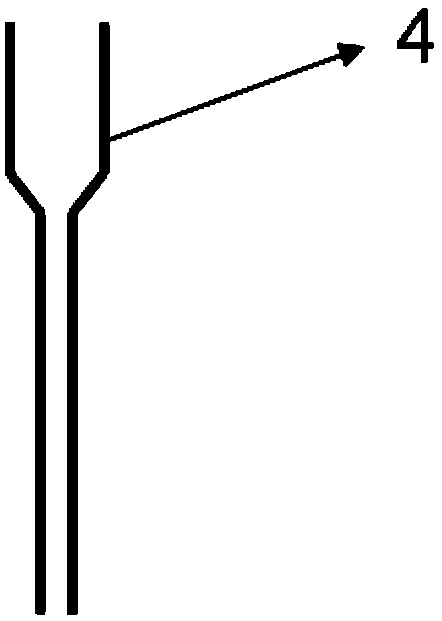

[0050] Maintenance method: injection needle 4 as figure 2 As shown, the front end is made of stainless steel, which can pierce the reverse valve 2, and the other end is connected to a three-way valve. One of the three-way valves is connected to a Hiba pump. bottle; the injection needle 4 accurately...

Embodiment 2

[0053] according to figure 1 Inlay the sealing ring with the reverse valve rubber block 2 made of nitrile rubber; stir the gel, electrolyte and zinc powder in a ratio of 1:50:100 to form a zinc paste, and then add 100ppm of iron impurities (according to the quality of zinc powder calculation); through the FDK460 production line, through the insertion of the positive electrode ring of the steel shell, the insertion of the diaphragm paper, the injection of zinc paste with impurities, the insertion of the current collector composed of copper nails, the bottom of the negative electrode and the sealing ring containing the reverse valve, curling and shaping to obtain Serviceable LR6 batteries;

[0054] Maintenance method: injection needle 4 as figure 2 As shown, the front end is made of stainless steel, which can pierce the reverse valve 2, and the other end is connected to a three-way valve. One of the three-way valves is connected to the Hiba pump, and the end of the Hiba pump i...

Embodiment 3

[0057] according to figure 1 Inlay the sealing ring with a reverse valve rubber block made of a blend of neoprene and silicone rubber; mix the gel, electrolyte and zinc powder in a ratio of 1:40:100 to form a zinc paste; pass through the FDK460 production line and pass through the steel shell Insert the positive electrode ring, insert the separator paper, inject the above-mentioned zinc paste, insert the current collector composed of copper nails, the negative electrode bottom and the sealing ring containing the reverse valve, crimp and shape the seal to obtain a maintainable LR6 battery;

[0058] Maintenance method: injection needle 4 as figure 2 As shown, the front end is made of stainless steel, which can pierce the reverse valve 2, and the other end is connected to a three-way valve. One of the three-way valves is connected to a Hiba pump, and the end of the Hiba pump is connected to an electrolyte storage tank, and the other is connected to an argon cylinder. ; The inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com