Oil-containing sludge smoldering treatment device

A treatment device and smoldering technology, which is applied in the direction of combustion product treatment, gas treatment, combustion methods, etc., can solve problems such as high equipment and safety requirements, secondary pollution, and complicated processes, so as to improve the efficiency of gas-liquid separation and avoid Waste of energy, effect of increasing separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

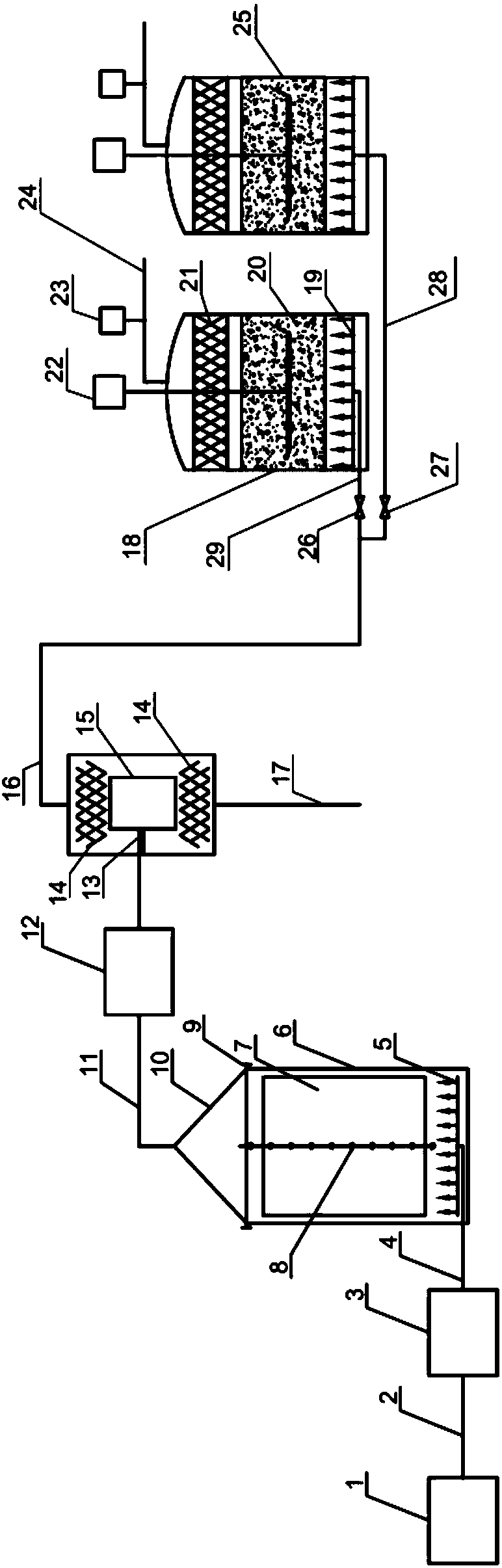

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

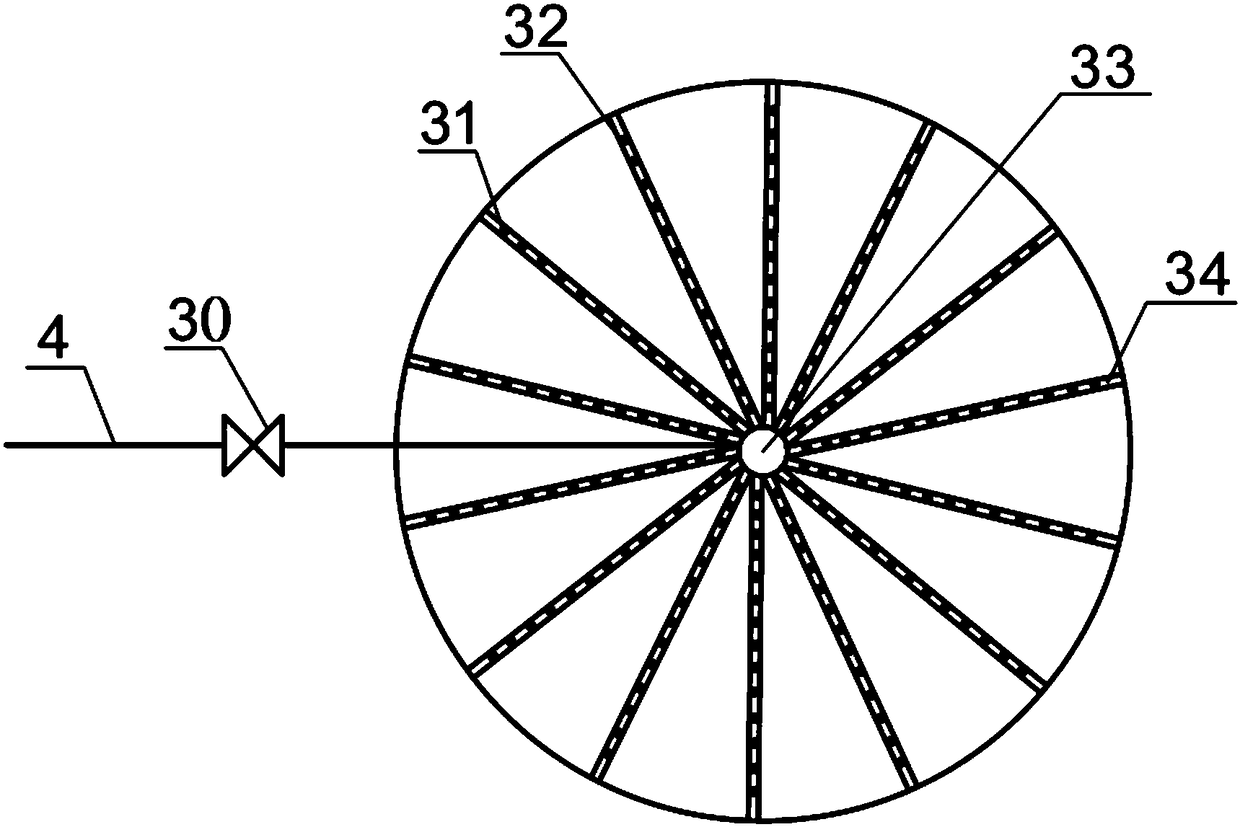

[0032] see figure 1 and figure 2, an oily sludge smoldering treatment device, including a fan 1, the outlet end of the fan 1 is connected to a heater 3 through a fan outlet pipeline 2, and the outlet end of the heater 3 is connected to a container containing oily sludge 7 through a hot gas inlet pipe 4 Smoldering furnace, the top of the smoldering furnace is connected to the cooler 12 through the steam output pipeline 11, the outlet end of the cooler 12 is connected with a gas-liquid cyclone separator, and the liquid outlet end of the gas-liquid cyclone separator is connected with clean water The gas outlet end of the exhaust pipe 17 is connected to the tail gas treatment device through the gas outlet pipeline 16 , and an exhaust pipe 24 is connected to the outlet end of the tail gas treatment device.

[0033] The smoldering furnace includes a smoldering furnace bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com