Method for preparing biodiesel from enzymatic oil

A biodiesel and oil technology, applied in biofuels, fermentation and other directions, can solve the problems of increasing difficulty, poor methanol solubility, and complicated operation process, and achieve good economic and social benefits, good operation stability, and reduced use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

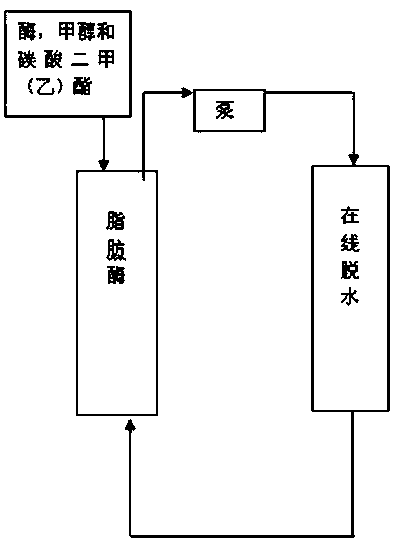

[0021] 10g of soybean oil, methanol (methanol:fat) based on a molar ratio of oil of 0.5 and dimethyl carbonate (dimethyl carbonate:fat) based on a molar ratio of fat of 3, based on 200 standard enzyme activities per unit of fat (200U / g soybean oil) derived from the lipase of Candida antarctica (Candida antarctica), placed in a single or multistage enzyme reactor suitable for enzymatic catalysis. The temperature is controlled at 35°C. During this reaction, the figure 1 In-line dehydration shown (membrane dehydration units including organic, inorganic or ceramic membranes and water absorption units including 3Å or 4Å molecular sieves). After 6 hours of reaction, the conversion rate of effective oil to biodiesel in the system was 98%, the acid value was 0.4mg KOH / g oil, and the total glycerol content was 0.18%.

Embodiment 2

[0023] With 10g lard, based on the methanol (methanol:fat) of 0.8 molar ratio of fat and dimethyl carbonate (dimethyl carbonate: fat) of 4 molar ratio of fat, based on the source of 200 standard enzyme activities per unit fat mass The lipase of Aspergillus oryzae is placed in a one-stage or multi-stage enzyme reactor suitable for enzyme catalysis. The temperature was controlled at 40° C., and in-line dehydration (including the water absorption device of the organic membrane) was carried out during the reaction. Reaction for 2 hours, reaction 8 sales, the conversion rate of effective oil to biodiesel in the system is 98.5%, the acid value is 0.3mg KOH / g oil, and the total glycerin is 0.17%.

Embodiment 3

[0025] 10g of palm oil, based on methanol (methanol: oil) with a molar ratio of oil of 0.6 and dimethyl carbonate (dimethyl carbonate: oil) based on a molar ratio of oil of 5, based on a source of 200 standard enzyme activities per unit oil mass The lipase from Thermomyces lanuginosus and the lipase from Aspergillus oryzae with 200 standard enzyme activities based on the unit oil mass are placed in a one-stage or multi-stage enzyme reactor suitable for enzyme catalysis middle. Temperature control 45 ℃, in this reaction process, carry out as follows figure 1 In-line dehydration shown (water absorption device including inorganic membrane). After 9 hours of reaction, the conversion rate of effective oil to biodiesel in the system was 98%, the acid value was 0.4mg KOH / g oil, and the total glycerol was 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com