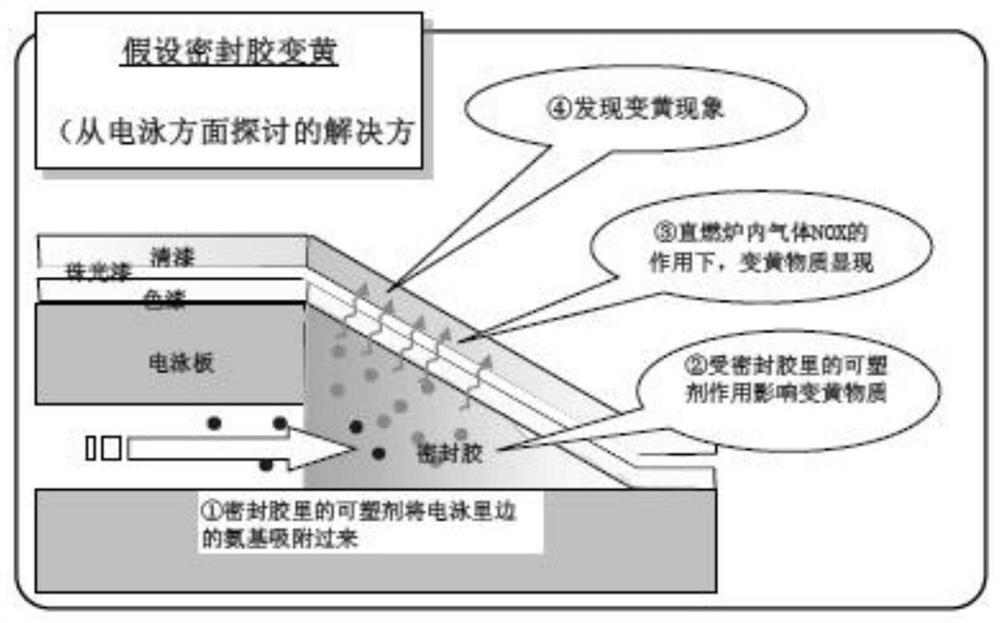

A cathodic electrophoretic coating for improving the yellowing of automobile sealant and its preparation method and application

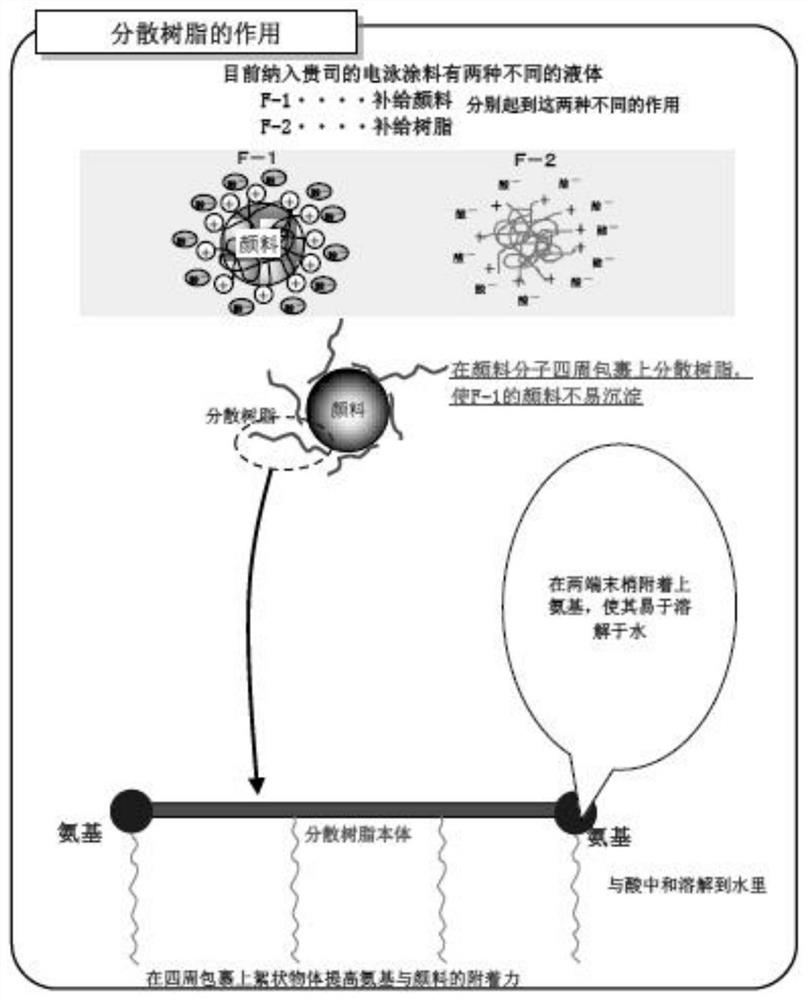

A technology of raw material and epoxy resin, which is applied in the synthesis of dispersion emulsion for cathodic electrophoretic coatings, can solve the problems of sealant yellowing, etc., and achieve the effects of reduced yellowing, reduced influence of yellowing reactivity, and good coating workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

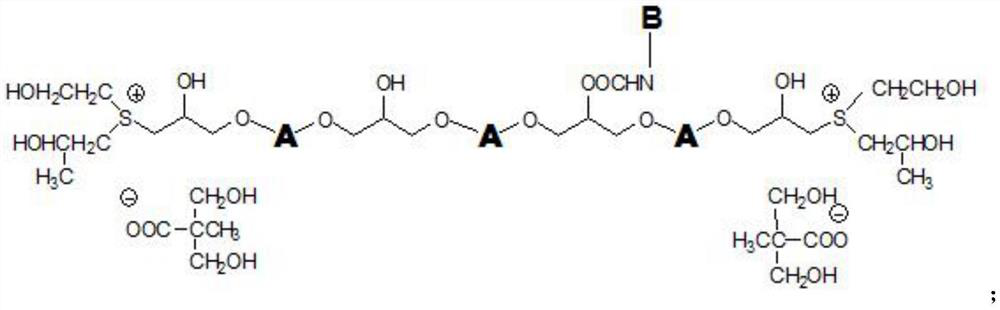

Method used

Image

Examples

Embodiment 1

[0127] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. It should be understood by those skilled in the art that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention with this.

[0128] Under the situation that the purpose of the present invention is clarified and explained by the following examples, the components of the composition are all explained in parts by weight as a general standard. Unless otherwise specified, for the sake of brevity, "parts" in the embodiments of the present invention have the same meaning as parts by weight.

[0129] Example 1

[0130] 1. Preparation of semi-blocked isocyanate (HBI), the formula is shown in the following table:

[0131] 1. The formula is shown in the table below:

[0132] Chinese name Feed weight:g Isophorone dii...

Embodiment 2

[0267] Same as Example 1, the difference is:

[0268] In the preparation of semi-blocked isocyanate (HBI):

[0269] The 2-ethylhexanol added to the blocking agent is changed to one or two of trimethylolpropane, methyl ethyl ketone oxime (MEKO), caprolactam, and ethylene glycol butyl ether, as long as the total equivalent ratio is 1:1;

[0270] The result is similar to Example 1.

Embodiment 3

[0272] Same as Example 1, the difference is:

[0273] In the preparation of semi-blocked isocyanate (HBI):

[0274] The polyisocyanate can be changed to aromatic, aliphatic, alicyclic diisocyanate or mixture thereof, such as TDI, P-MDI, IPDI, HDI and their polymers, as long as the equivalent ratio remains unchanged. ;

[0275] The result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com