Preparation method of conductive polyether ether ketone composite material

A composite material, polyether ether ketone technology, applied in the field of preparation of conductive polyether ether ketone composite materials, to achieve high mechanical properties, long-term use effect improvement, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

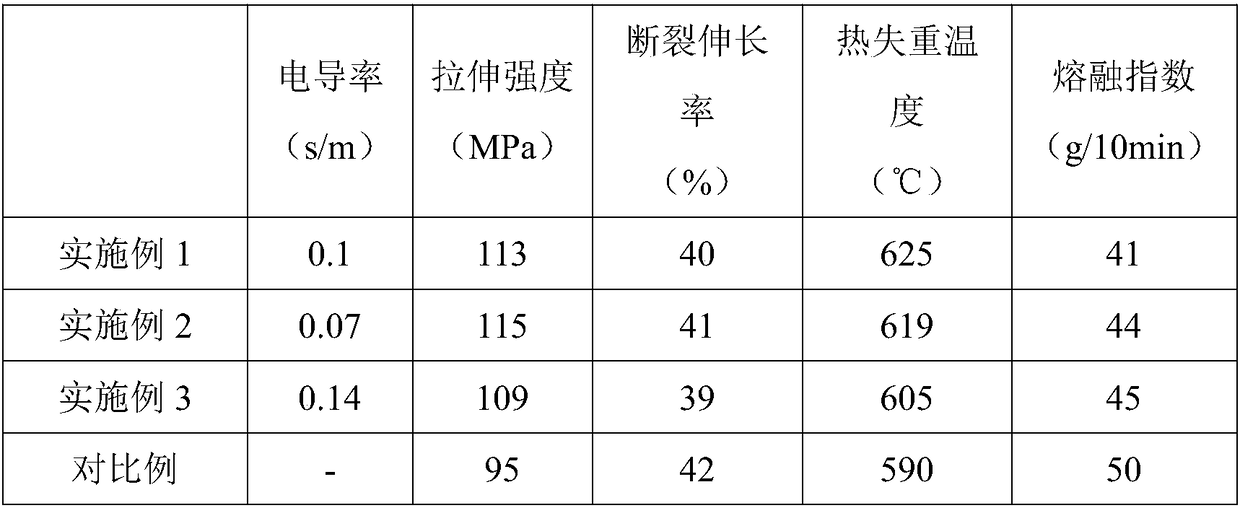

Examples

Embodiment 1

[0039] 1. Put 5 parts of multi-walled carbon nanotubes into 89 parts of dimethylacetamide, perform ultrasonication at 55°C for 30 minutes, then put 5 parts of carbon fibers into the above mixture, and carry out at 55°C Ultrasound, ultrasonic for 30min, put 1 part of polyetherimide into the above mixing system, at 60°C, continue to ultrasonicate for 480min and filter, rinse with boiling deionized water for 10 times, put the filtrate into 170°C for vacuum drying The environment is dried, and the drying time is 120min;

[0040] 2. Using a two-dimensional high-speed mixer, 5 parts of the dry material in step 1, 90 parts of polyetheretherketone micropowder, 2 parts of graphite, and 3 parts of GPPS are mixed at high speed, the mixing speed is 800r / min, and the mixing time is 60min;

[0041] 3. Put the mixed material in step 2 into an extrusion granulator for mixing and granulation, the processing temperature is 375°C, and the screw speed is 35r / min;

[0042] 4. Put the granulated p...

Embodiment 2

[0044] 1. Put 5 parts of multi-walled carbon nanotubes into 89 parts of dimethylacetamide, perform ultrasonication at 55°C for 30 minutes, then put 5 parts of carbon fibers into the above mixture, and carry out at 55°C Ultrasound, ultrasonic for 30min, put 1 part of polyetherimide into the above mixing system, at 60°C, continue ultrasonication for 480min and filter, rinse with boiling deionized water for 9 times, put the filtrate into 170°C for vacuum drying The environment is dried, and the drying time is 120min;

[0045] 2. Using a two-dimensional high-speed mixer, 10 parts of the dry material in step 1, 86 parts of polyether ether ketone micropowder, 2 parts of graphite, and 2 parts of GPPS were mixed at high speed, the mixing speed was 900r / min, and the mixing time was 60 minutes;

[0046] 3. Put the mixed material in step 2 into an extrusion granulator for mixing and granulation, the processing temperature is 375°C, and the screw speed is 35r / min;

[0047] 4. Put the gra...

Embodiment 3

[0049] 1. Put 5 parts of multi-walled carbon nanotubes into 89 parts of dimethylacetamide, perform ultrasonication at 55°C for 30 minutes, then put 5 parts of carbon fibers into the above mixture, and carry out at 55°C Ultrasound, ultrasonic for 30min, take 1 part of polyetherimide into the above mixing system, at 60°C, continue ultrasonication for 480min and filter, rinse with boiling deionized water 8 times, put the filtrate into 170°C for vacuum drying The environment is dried, and the drying time is 120min;

[0050] 2. Use a two-dimensional high-speed mixer to mix 1 part of the dry material in step 1, 90 parts of polyetheretherketone micropowder, 4 parts of graphite, and 5 parts of GPPS at a high speed. The mixing speed is 1000r / min, and the mixing time is 60 minutes;

[0051] 3. Put the mixed material in step 2 into an extrusion granulator for mixing and granulation, the processing temperature is 375°C, and the screw speed is 35r / min;

[0052] 4. Put the granulated produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com