High hardness nitrile rubber and preparation method thereof

A technology of nitrile rubber and high hardness, which is applied in the field of rubber to achieve high performance and economic benefits, improve tensile strength, increase hardness and bridging density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of high hardness nitrile rubber is made by the raw material of following weight: nitrile rubber 100g, zinc oxide 3.5g, stearic acid 1g, antioxidant 1.5g, octyl phenolic tackifying resin 2.0g, carbon Black 100g, softener 6g, vulcanizing agent 2.0g, accelerator 1.5g.

[0017] Described antioxidant is made up of 0.5g antioxidant RD and 1.0g antioxidant 4010NA; Described carbon black is made up of 85 parts of carbon black SP5000 and 15 parts of carbon black N990; Described softening agent is made up of 3g DOP and 3g PL- 400 composition; the vulcanizing agent is composed of 0.5g sulfur and 1.5g vulcanizing agent DCP; the accelerator is composed of 1.0g accelerator DM and 0.5g accelerator TMTD.

[0018] Correspondingly, the preparation method of this high hardness nitrile rubber material may further comprise the steps:

[0019] Add nitrile rubber to the internal mixer, masticate for 150 seconds at 45°C, add the above-mentioned parts by weight of zinc oxi...

Embodiment 2

[0020] Embodiment 2: a kind of high hardness nitrile rubber, is made by the raw material of following weight: nitrile rubber 100g, zinc oxide 5g, stearic acid 1g, antioxidant 2.5g, octyl phenolic tackifying resin 3.0g, carbon black 115g, softener 8g, vulcanizing agent 3.5g, accelerator 2.0g.

[0021] Described antioxidant is 2.5 parts of antioxidant RD; Described carbon black is made up of 80 parts of carbon black N220 and 35 parts of carbon black N330; Described softening agent is 8 parts of DOP; Described vulcanizing agent is 3.5 parts of sulfur; The accelerator consisted of 0.9 parts of accelerator DM and 1.1 parts of accelerator CZ. Its preparation method is the same as the preparation method described in Example 1. The performance test results of the prepared high hardness nitrile rubber material are shown in Table 1.

Embodiment 3

[0022] Embodiment 3: a kind of high hardness nitrile butadiene compounded rubber, is made by the raw material of following weight: nitrile butadiene rubber 100g, zinc oxide 7g, stearic acid 1g, anti-aging agent 3.5g, octyl phenolic tackifying resin 4.0g, Carbon black 120g, softener 10g, vulcanizing agent 4.0g, accelerator 3.0g.

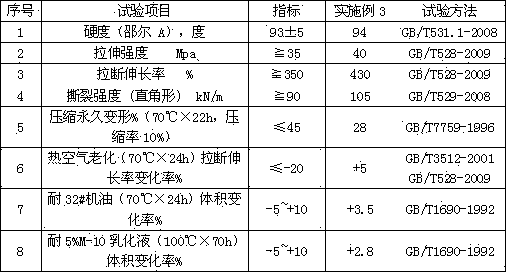

[0023] Described antioxidant is 3.5g antioxidant 4010NA; Described carbon black is made up of 90g carbon black N220 and 30g carbon black N550; Described softening agent is 10g PL-400; Described vulcanizing agent is 4.0g vulcanizing agent DCP; The accelerator is composed of 1.5g accelerator CZ and 1.5g accelerator TMTD. Its preparation method is the same as the preparation method described in Example 1. The performance test results of the prepared high hardness nitrile rubber material are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com