Method for preparing torreya grandis activated carbon

A technology of activated carbon and torreya, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low adsorption performance of iodine and methylene blue, and achieve the effect of improving adsorption performance and maintaining internal porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

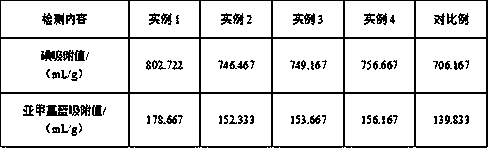

Examples

example 1

[0020] Put the torreya husk in an oven and dry to constant weight at a temperature of 110°C to obtain dried torreya husks, and put the dried torreya husks into a pulverizer. After crushing, pass a 120-mesh sieve to obtain torreya husks. Pour the obtained torreya husk powder and enzyme solution into a beaker, and move the beaker into a digital speed-measuring constant-temperature magnetic stirrer at a temperature of 40°C and a rotational speed of 500r / min. After 4 hours of constant temperature stirring, , Warm up to 95℃, keep the enzyme inactivated for 20min, filter to obtain filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to the oven, and dry to constant weight at 110℃ , Get the enzymatic hydrolysate; mix the enzymatic hydrolysate with 10% sodium fluoride solution at a mass ratio of 1:15, immerse it in an ultrasonic frequency of 55kHz for 60 minutes, and filter to obtain a filter residue. The filter residue is dried a...

example 2

[0022] Put the torreya husk in an oven and dry to constant weight at a temperature of 110°C to obtain dried torreya husks, and put the dried torreya husks into a pulverizer. After crushing, pass a 120-mesh sieve to obtain torreya husks. Pour the obtained torreya husk powder and enzyme solution into a beaker, and move the beaker into a digital speed-measuring constant-temperature magnetic stirrer at a temperature of 40°C and a rotational speed of 500r / min. After 4 hours of constant temperature stirring, , Warm up to 95℃, keep the enzyme inactivated for 20min, filter to obtain filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to the oven, and dry to constant weight at 110℃ , Get the enzymatic hydrolysate; take 100 parts of isocyanate, 30 parts of tetraethyl orthosilicate, 5 parts of nano iron powder, 10 parts of expanded perlite with a mesh size of 500 meshes in order in parts by weight. After mixing, the ultrasonic freque...

example 3

[0024] Put the torreya husk in an oven and dry to constant weight at a temperature of 110°C to obtain dried torreya husks, and put the dried torreya husks into a pulverizer. After crushing, pass a 120-mesh sieve to obtain torreya husks. Pour the obtained torreya husk powder and enzyme solution into a beaker, and move the beaker into a digital speed-measuring constant-temperature magnetic stirrer at a temperature of 40°C and a rotational speed of 500r / min. After 4 hours of constant temperature stirring, , Warm up to 95℃, keep the enzyme inactivated for 20min, filter to obtain filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to the oven, and dry to constant weight at 110℃ , Get the enzymatic hydrolysate; mix the enzymatic hydrolysate with 10% sodium fluoride solution at a mass ratio of 1:15, immerse it in an ultrasonic frequency of 55kHz for 60 minutes, and filter to obtain a filter residue. The filter residue is dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com