Semi-automatic stamp making machine

A kind of stamping machine and semi-automatic technology, applied in the field of stamping machines, can solve the problems of physical exhaustion and waste of time of printing users, and achieve the effect of saving printing time and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0073] This embodiment is a concrete embodiment of the semi-automatic stamp machine of the present invention.

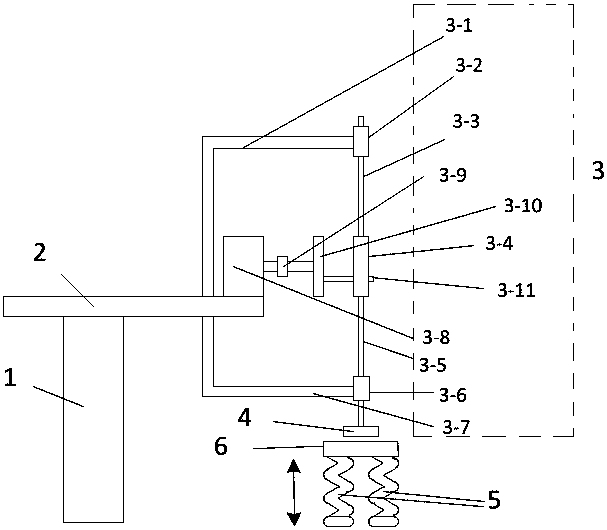

[0074] The semi-automatic stamp machine of the present embodiment, structural representation is as figure 1 As shown, it includes a bracket 1, a stage 2, a continuously controlled reciprocating intermittent motion platform 3, a stamp 4 and a two-dimensional paper clamping structure 6;

[0075] The support 1 is placed vertically, the top of the support 1 is equipped with a loading platform 2, and the front end of the loading platform 2 is equipped with a continuous control reciprocating intermittent motion platform 3;

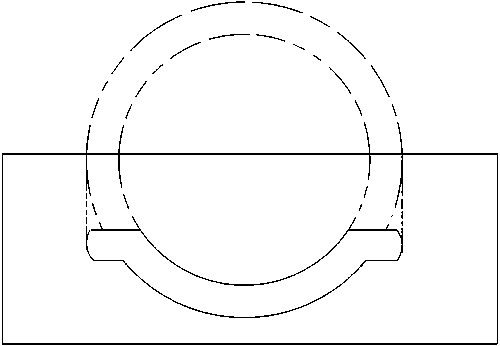

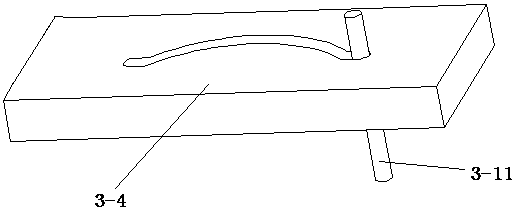

[0076] The continuous control reciprocating intermittent motion platform 3 includes an upper fixed bracket 3-1, an upper fixed end 3-2, an upper rod 3-3, a moving block 3-4, a lower rod 3-5, and a lower fixed end 3-6, Lower fixed support 3-7, motor 3-8, shaft coupling 3-9, T-type turntable 3-10 and limit projection 3-11; The position of described uppe...

specific Embodiment 2

[0083] This embodiment is a specific embodiment of the spring of the present invention.

[0084] In a semi-automatic stamp machine, the bottom of the two-dimensional paper clamping structure 6 is provided with a supporting spring 5, and when the supporting spring 5 is only compressed by the two-dimensional paper clamping structure 6, the upper surface of the two-dimensional paper clamping structure 6 is higher than that of the stamp 4 In the lowest moving position, when the support spring 5 is fully compressed, the upper surface of the two-dimensional paper clamping structure 6 is lower than the lowest moving position of the stamp 4 .

[0085] When the semi-automatic stamp machine is in motion, under the rotation of the motor 3-8, the moving block 3-4 realizes the reciprocating intermittent movement; The intermittent movement drives the stamp 4 to reciprocate intermittently; during the downward movement of the stamp 4, the two-dimensional paper clamping structure 6 is pressed,...

specific Embodiment 3

[0086] This embodiment is a specific embodiment determined by the continuous control of the reciprocating intermittent motion platform of the present invention.

[0087] The continuous control reciprocating intermittent motion platform of this embodiment, on the basis of specific embodiment one or specific embodiment two, such as Figure 4 The flow shown further defines the motion block 3-4 to determine the parameters by the following steps:

[0088] In the semi-automatic stamping machine, the movement block 3-4 determines parameters through the following steps:

[0089] Step a, according to the running time t of the motion block 3-4 1 and dead time t 2 ,Sure:

[0090] The running cycle is T=t 1 +t 2 , the operating angle is and the stagnation angle is

[0091] Step b, according to the running distance s of the moving block, determine the radius r of the inferior arc slot;

[0092] r=s / 2;

[0093] Step c, according to the radius r of the inferior arc through groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com