Shot blasting cleaning device

A technology of shot blasting cleaning and assembling holes, applied in explosion generating devices, abrasives, metal processing equipment, etc., can solve problems such as limited improvement, and achieve the effect of reducing the number of pieces, prolonging the replacement cycle, and reducing the amount of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

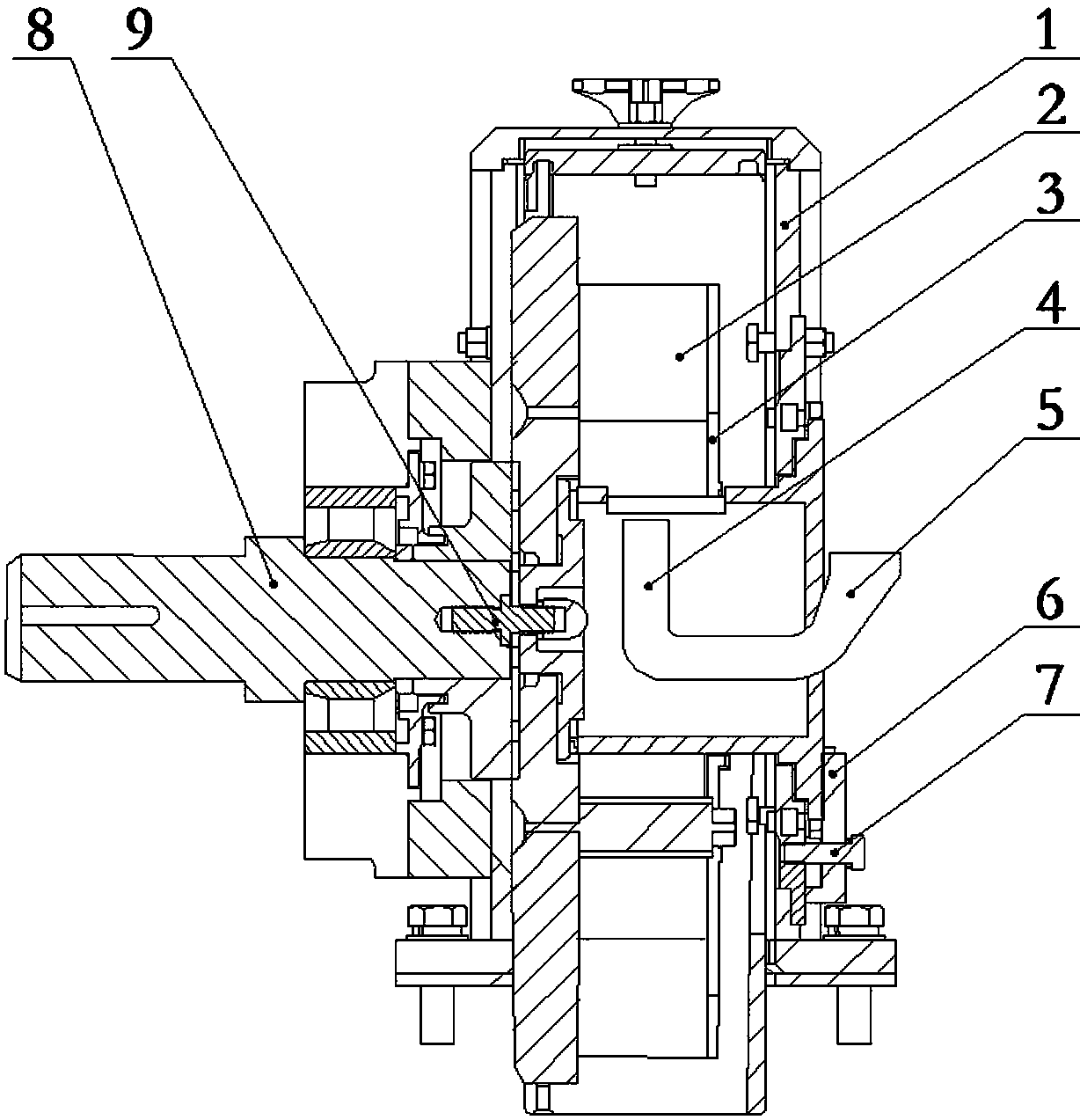

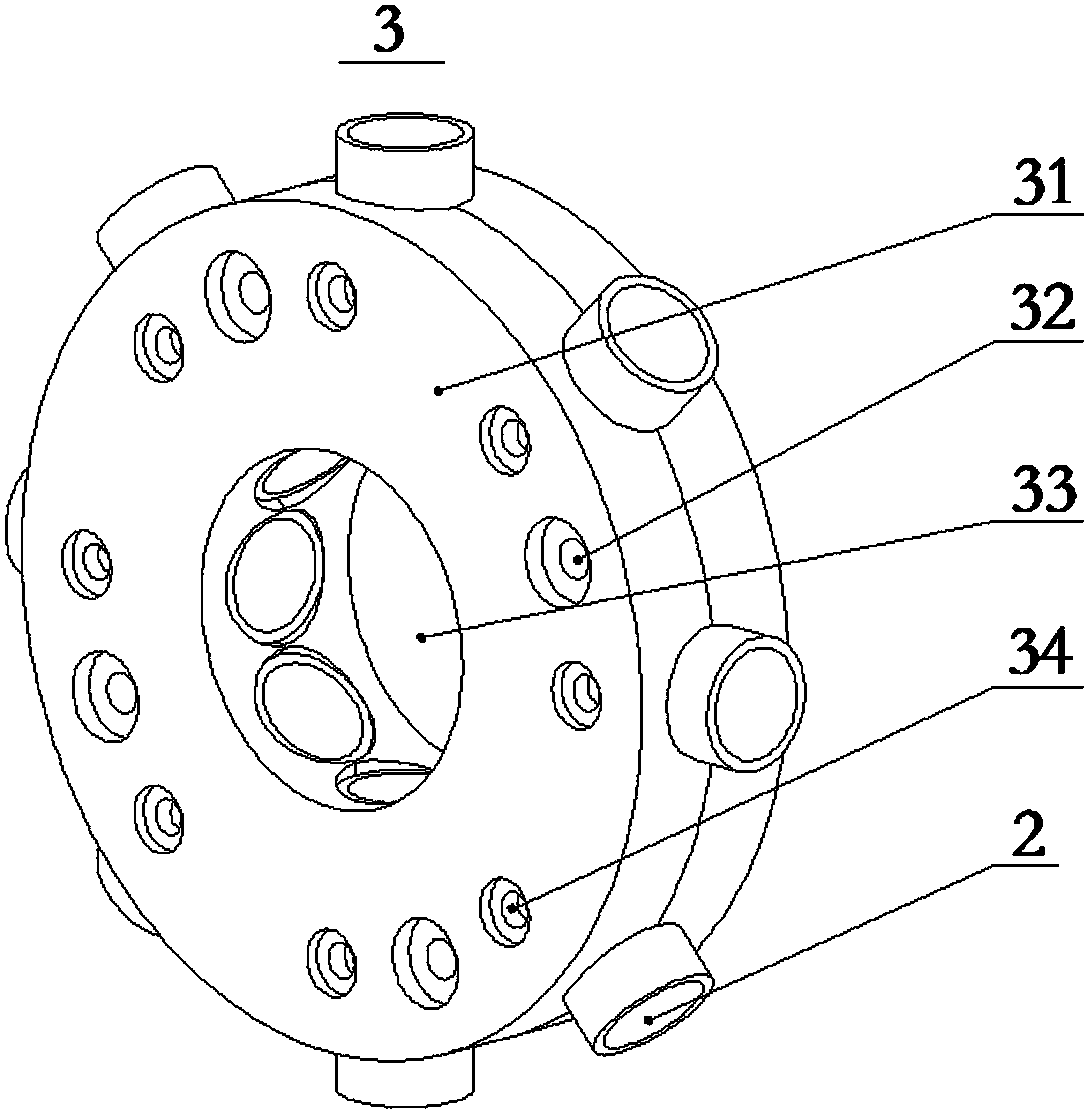

[0033] exist figure 1 In the shown structure, the main frame part of the shot blasting cleaning device is the shell 1, and the shell 1 generally includes a seat shell (not shown in the figure), and the seat shell is generally used for the installation of the shot blasting machine, for example, on the ground installed or installed on other basis. The seat shell is generally formed by casting process, and the structure is relatively simple. Therefore, it is usually necessary to configure other parts for the shell 1 to integrate into a complete shell 1. For example, in the axial direction of the impeller 3, the shell 1 usually has two End cover, one end cover is used for assembling motor, and another end cover generally has central hole, is used for introducing such as and enters pill pipe 5.

[0034] Because in the embodiment of the present invention, the shot tube 5 does not have to match the position of the shot wheel for example, therefore, the central hole for introducing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com