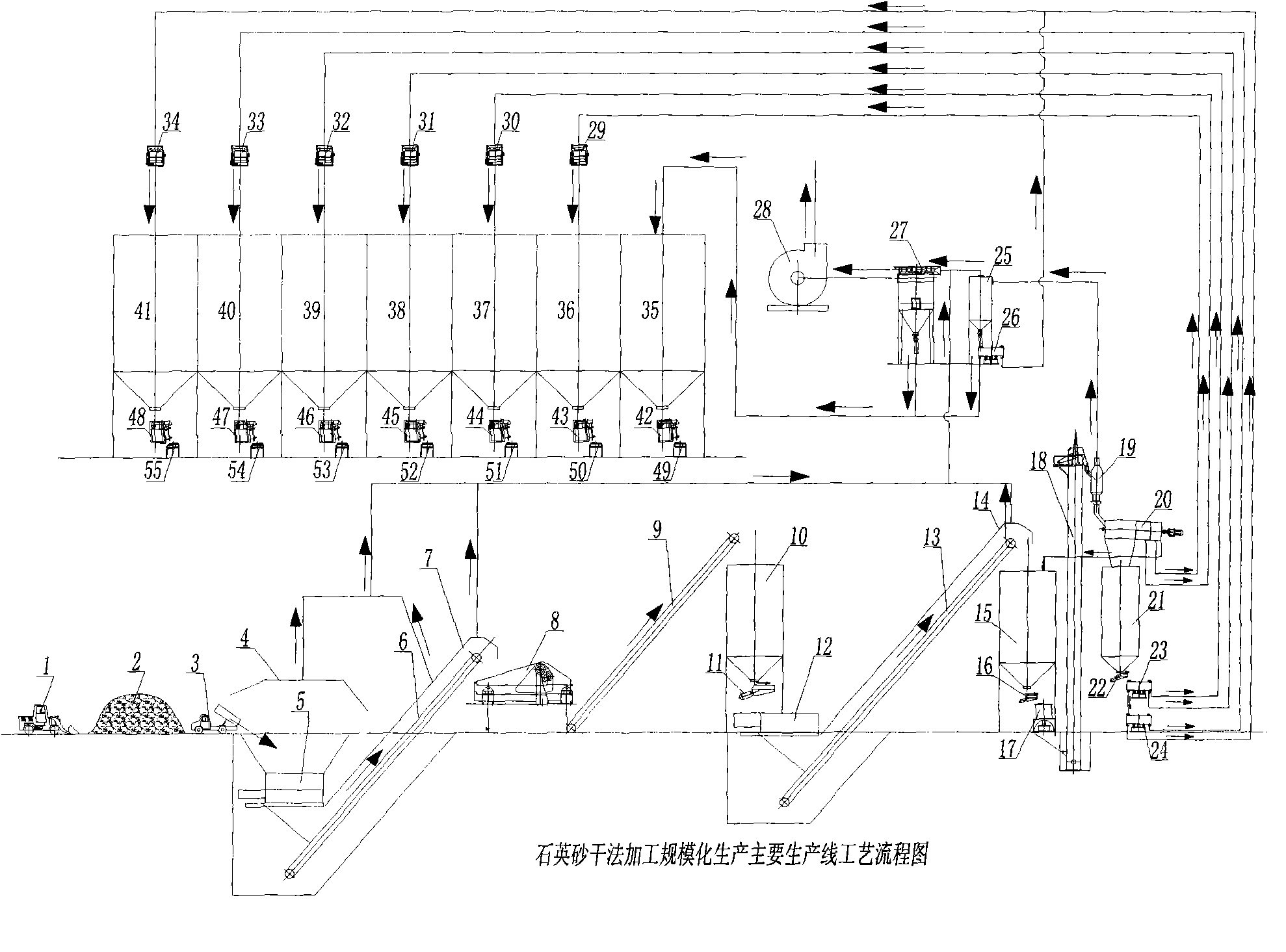

Dry process scale continuous production process of quartz sand

A production process and dry processing technology, applied in the direction of manufacturing tools, chemical instruments and methods, solid separation, etc., can solve the problems of frequent replacement of hammer heads, high labor intensity of workers, troubled large-scale production, etc., and easy to achieve process layout and feasible, the labor intensity of workers is reduced, and the effect of eliminating dust flying pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] exist figure 1 In the process, the quartz ore raw material is sent to the primary crushing and screening crusher (5) by an agricultural vehicle or loader (3) for crushing, and the crushed material is sent to the cleaning and dehydrating screen (8) by the No. 1 feeding conveyor (6). The sand and other impurities are removed from the medium, and then sent to the crushed stone drying tower (10) by the No. 2 feeding conveyor (9) for drying, and the dried material is evenly fed by the vibrating feeder (11) until it is screened and crushed by the medium crushing machine. Further broken in the machine (12), sent to crushed stone silo (15) by No. 3 feeding conveyor (13). The gravel silo (15) is an elongated silo (the distributing of the silo is realized by the material guide belt conveyor erected on the top), and the feeders (16) of multiple sets of units are set below the silo, feeding to each The HK-type sand making machine (17) feeds the material (to realize the joint opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com